Novel integrated microbial fuel cell for leachate treatment

A technology of fuel cells and microorganisms, applied in the field of new integrated microbial fuel cells, can solve the problems of low operating costs, high mass transfer resistance, high cost membranes, etc., to reduce consumption and waste, realize regeneration, and reduce the area occupied by the device Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

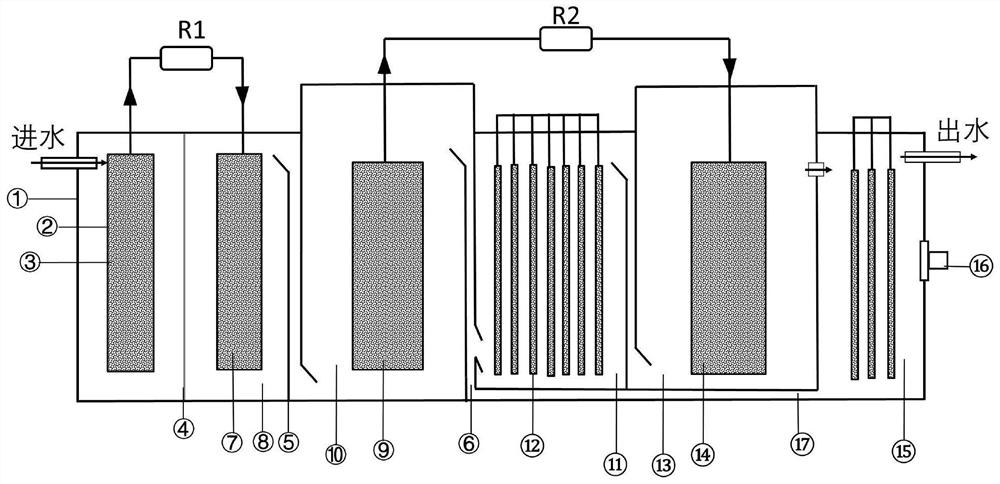

[0021] Such as figure 1 As shown, a new type of integrated microbial fuel cell for leachate treatment, including anaerobic No. 1 anode chamber 1, anaerobic No. 1 cathode chamber 8, anaerobic methane denitrification No. Oxygen ammonium oxidation chamber 11, anaerobic methane denitrification No. 2 cathode chamber 13 and nitrosation reaction chamber 15, anaerobic No. 1 anode chamber 1 is provided with a water inlet on the left side, anaerobic No. The electrode partitions are carried out between the chambers 8 through the cation exchange membrane 4, the protons are transferred with the flow state of the reactor through the baffle 5 between the anaerobic No. 1 cathode chamber 8 and the anaerobic methane denitrification No. Nitrification No. 2 anode chamber 10 and anammox chamber 11, and anammox chamber 11 and anaerobic methane denitrification No. 2 cathode chamber 13 are all connected by overflow channel 6, and nitrosation reaction chamber 15 is set There is a micro-aeration syste...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap