Polyfluorene-based side-chain anion exchange membrane and preparation method thereof

An anion exchange membrane and side chain technology, applied in the field of polyfluorene-based side chain type anion exchange membrane and its preparation, to achieve the effects of enhancing flexibility, improving flexibility and solubility, and reducing inductive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

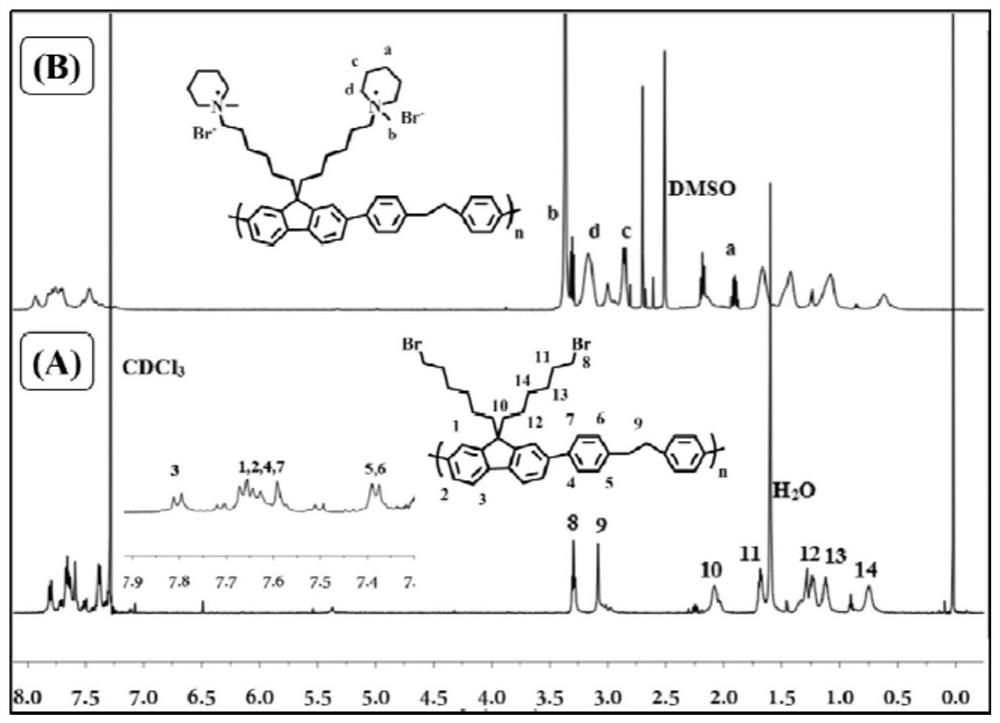

Method used

Image

Examples

Embodiment 1

[0029] 2,7-dibromofluorene (5.0g, 15mmol), 1,6-dibromohexane (30ml) and tetrabutylammonium bromide (0.1g) were dissolved in tetrahydrofuran with stirring at 60°C. Under nitrogen protection, NaOH solution (30ml, 50wt%) was added slowly. The mixture was reacted for 8 hours. Then the reaction solution was extracted with dichloromethane, and the dried organic layer was collected. The crude product was separated and purified by column chromatography with n-hexane to obtain 9,9-dibromohexyl-2,7-dibromofluorene with a yield of 82%.

[0030] 9,9-dibromohexyl-2,7-dibromofluorene, bis(pinacol and) diboron (3.0 g, 12 mmol), potassium acetate (3.5 g, 35.5 mmol) and (PdCl 2 )(dppf) (250mg) was dissolved in 50ml of toluene. Under the protection of nitrogen, the reaction was stirred at 85° C. for 24 hours. The reaction solution was extracted with dichloromethane and water, and the dried organic layer was collected. The crude product was separated and purified by column chromatography wi...

Embodiment 2

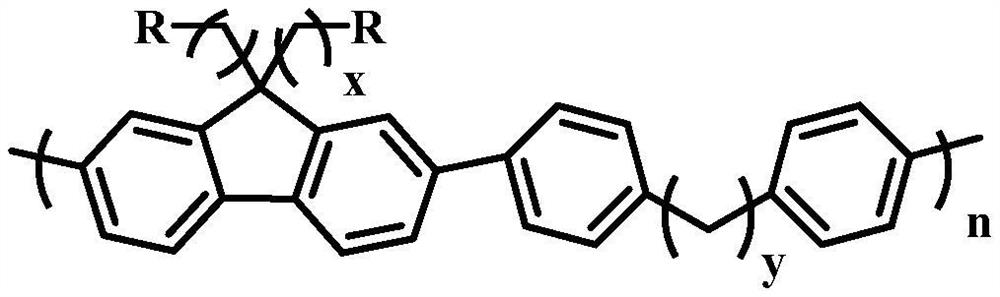

[0036] This example is similar to Example 1, except that 1,4-dibromobutane is used to substitute and graft the 9th position of fluorene, and the structure of the finally prepared polyfluorene-based side chain anion exchange membrane is:

[0037]

[0038] The prepared polyfluorene-based side-chain anion exchange membrane has an ion conductivity of 70.24 mScm at 80 °C -1 , The degree of swelling at 80°C is only 8.48%. When the film was soaked in 2M KOH solution at 80 °C for 30 days, the conductivity lost only 8%, showing excellent alkali resistance stability.

Embodiment 3

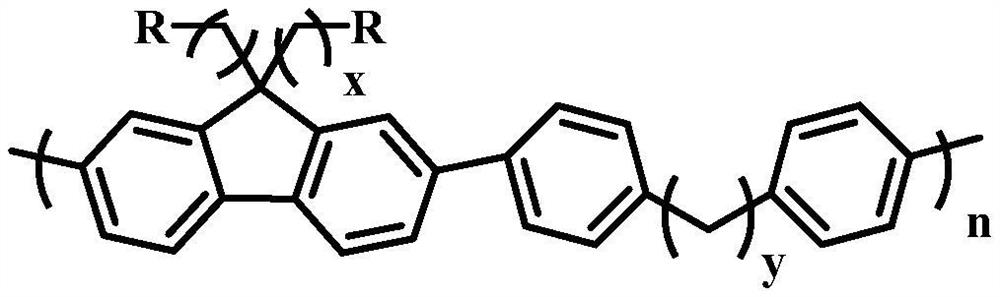

[0040] This example is similar to Example 1, except that in the final quaternization process, 1,2-dimethylimidazole is selected, and the structure of the finally prepared polyfluorene-based side chain anion exchange membrane is:

[0041]

[0042] The prepared polyfluorene-based side-chain anion exchange membrane has an ion conductivity of 78.24 mScm at 80 °C -1 , The degree of swelling at 80°C is only 7.18%. When the film was soaked in 2M KOH solution at 80 °C for 30 days, the conductivity lost only 8%, showing excellent alkali resistance stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com