Tin smelting intermediate material treatment system and treatment method thereof

A processing system and feeding system technology, applied in the tin smelting intermediate material processing system and its processing field, can solve the problems of difficult sales and transportation of hazardous waste materials, loss of operating profits, low valuation coefficient, etc., and achieve saving of procurement costs and high value Full recovery and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

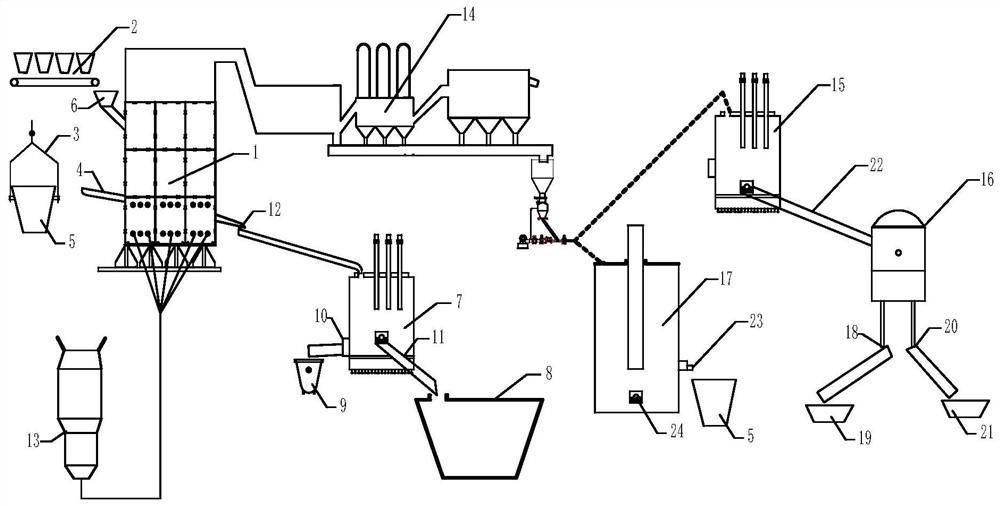

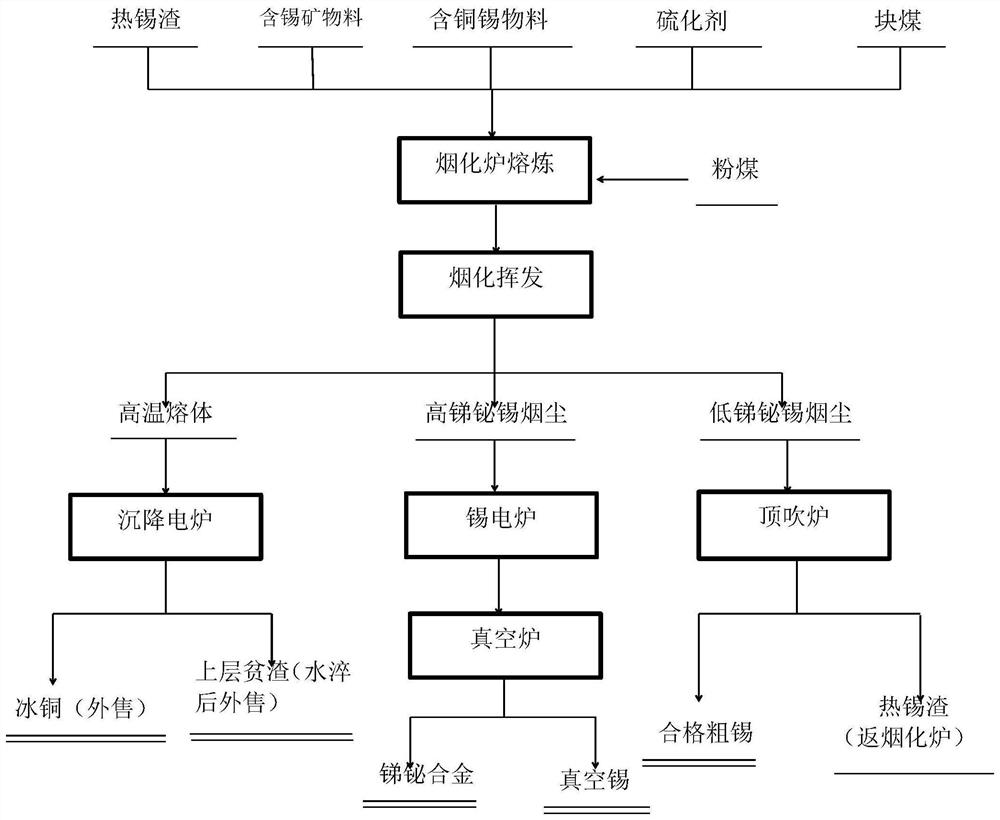

[0038] Such as figure 1 As shown, this embodiment provides a tin smelting intermediate material processing system, including: fuming furnace 1, settling electric furnace 7, poor slag water quenching pool 8, matte copper bag 9, pulverized coal injection system 13, flue gas treatment system and secondary air supply system;

[0039] The fuming furnace 1 is respectively connected with the subsidence electric furnace 7, the pulverized coal injection system 13, the flue gas treatment system and the secondary air supply system;

[0040] The settling electric furnace 7 is also connected with the poor slag water quenching pool 8 and the matte copper bag 9 respectively.

[0041] Furnace top belt feeding system 2 and hook scale system 3; intermediate materials for tin smelting include hot tin slag, tin-containing copper mineral materials and lump coal; hot tin slag is fed into fuming furnace 1 through hook scale system 3, containing tin Copper ore materials and lump coal are fed into t...

Embodiment 2

[0050] Utilize the processing system that embodiment 1 provides, take fuming furnace as an example according to the high-temperature melt amount of processing 100 tons, processing method is:

[0051] (a) Preparation of the fuming furnace: before the fuming furnace is ready, keep the temperature of the flue gas in the furnace at 600°C;

[0052] (b) Receiving hot tin slag: through the hook scale system, lift the hot tin slag transfer slag package, feed the hot tin slag into the chute to introduce the hot tin slag into the fuming furnace, and weigh and measure the hot tin slag weight with the hook scale ;

[0053] (c) Furnace top belt feeding: After receiving the hot tin slag in the fuming furnace, start the furnace top belt feeding system, and add mixed tin-containing mineral materials, copper-tin-containing materials, and high-sulfur copper concentrate to the fuming furnace , Lump coal, evenly added within 60 minutes;

[0054] (d) Heating up smelting: After the top belt feedi...

Embodiment 3

[0063] Utilize the treatment system that embodiment 1 provides, take fuming furnace as an example according to the high-temperature melt amount that handles 120 tons:

[0064] (a) Preparation of the fuming furnace: before the fuming furnace is ready, keep the temperature of the flue gas in the furnace at 700°C;

[0065] (b) Receiving hot tin slag: through the hook scale system, lift the hot tin slag transfer slag package, feed the hot tin slag into the chute to introduce the hot tin slag into the fuming furnace, and weigh and measure the hot tin slag weight with the hook scale ;

[0066] (c) Furnace top belt feeding: After receiving the hot tin slag in the fuming furnace, start the furnace top belt feeding system, and add mixed tin-containing mineral materials, copper-tin-containing materials, and high-sulfur copper concentrate to the fuming furnace , Lump coal, evenly added within 70min;

[0067] (d) Heating up smelting: After the top belt feeding of the fuming furnace is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com