Adsorption desulfurizer capable of being thermally regenerated and having COS hydrolysis function as well as preparation method and application of adsorption desulfurizer

A technology of adsorption desulfurization and thermal regeneration, applied in the direction of sulfur preparation/purification, chemical instruments and methods, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

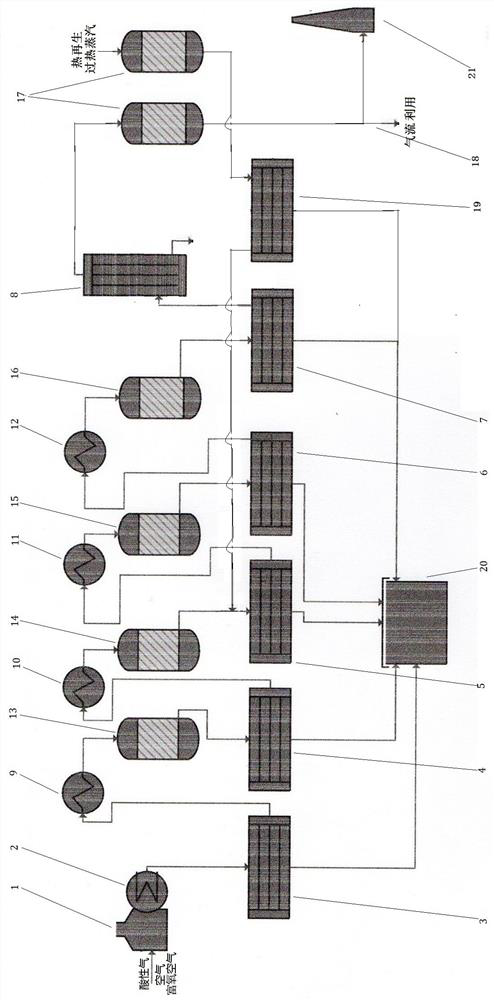

Method used

Image

Examples

Embodiment 1-8、 comparative example 1-6

[0043] Prepare the adsorption desulfurizer of the ratio of Table 1 as follows:

[0044] A. Coal-based columnar activated carbon carrier with large pores is 100g, the pore volume is 0.65mL / g, and the specific surface area is 420m 2 / g, outer diameter 3.0mm, length 4-7mm, equal volume impregnated ferric nitrate solution of required concentration, dried at 120°C for 5 hours, cooled and equal volume impregnated with required concentration of sodium hydroxide solution, airtightly placed for reaction for 10 hours and washed with water until Wash out water Na + The concentration is lower than 40ppm, and dried at 130°C for 3 hours to produce ferric hydroxide / activated carbon semi-finished product; the amount of alkali in the sodium hydroxide solution is 1.10 times the amount required to completely react with the iron salt to form ferric hydroxide;

[0045] B. Measure the water absorption of ferric hydroxide / activated carbon semi-finished products, impregnate the required concentratio...

Embodiment 9-10

[0050] 50g of the adsorption desulfurizers of Examples 1 and 3 were each taken, and heat-treated in a tube furnace and 320°C normal-pressure superheated steam flow for 80hr, as the adsorption desulfurizers of Examples 9-10; Last change.

Embodiment 11

[0052] Using a tube furnace, take homemade (BDBU) PF 6 Two portions of 5.00g each were placed in a porcelain boat, and were treated in a 320°C normal-pressure nitrogen flow and a 320°C normal-pressure superheated steam flow for 80 hours respectively, and the weight loss by heat measurement was less than 1%; the samples before and after treatment were analyzed by infrared, and the results were The comparison shows that there is no thermal decomposition or generation of other substances, which is also consistent with the standard spectrum of the substance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com