Self-repairing gutta-percha shape memory elastomer as well as preparation method and application thereof

A technology of eucommia gum and elastomer is applied in the field of shape memory material preparation to achieve the effect of simple preparation method and excellent self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a method for preparing a self-reinforcing, self-repairing, and recyclable Eucommia gum shape-memory elastomer, including:

[0048] (1) Dissolving 10 g of Eucommia gum in the organic solvent toluene to make a 3% solution, adding 18 mmol of acetic acid and 27 mmol of hydrogen peroxide, reacting at 30° C. for 6 h, and obtaining the product A modified Eucommia gum through precipitation, washing and drying;

[0049] (2) 10g modified Eucommia gum, 1g Eucommia gum, 0.1g oxalic acid, 0.2g tetrabutylammonium chloride, 0.2g zinc nitrate are dissolved in toluene, fully mixed;

[0050] Precipitate with organic solvent ethanol, wash, dry, and finally vulcanize at 180°C and 15MPa for 20 minutes to obtain the shape memory elastomer of Eucommia gum.

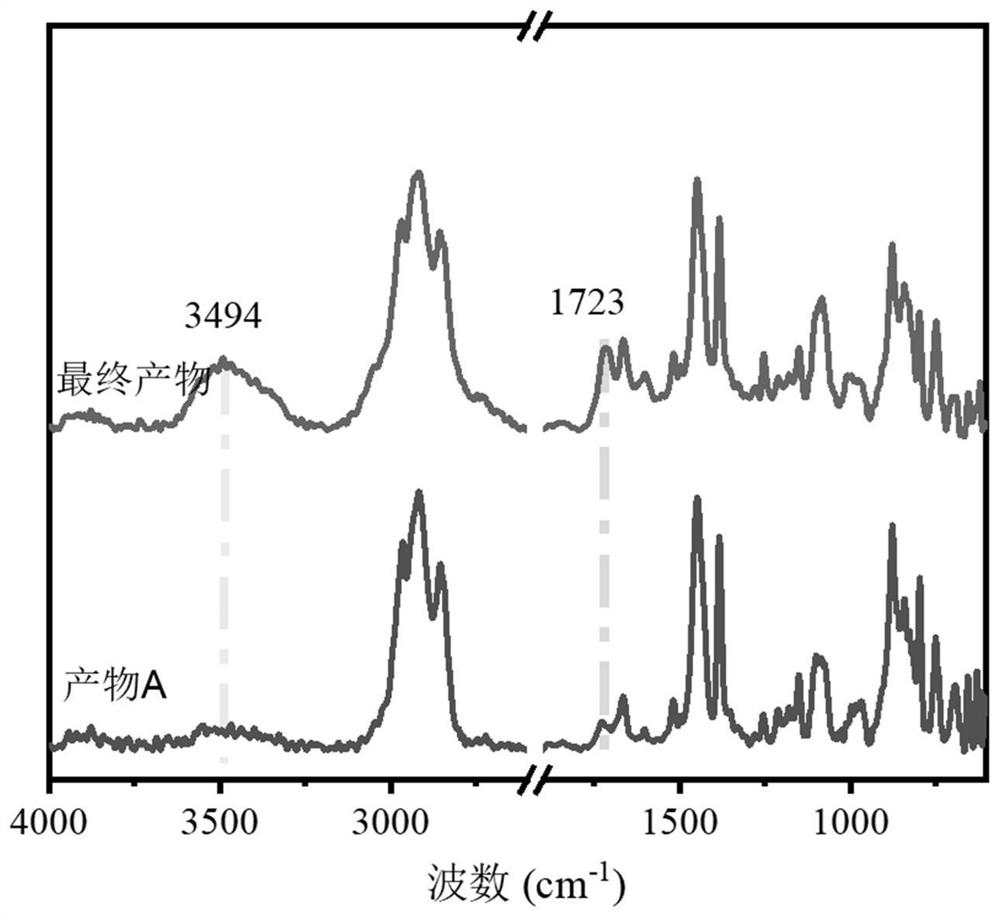

[0051] Such as figure 1 As shown, compared with product A modified Eucommia gum, the final product Eucommia gum shape memory elastomer obtained after vulcanization is 1723cm -1 (C=O stretching vibration) and 349...

Embodiment 2

[0053] This embodiment provides a method for preparing a self-reinforcing, self-repairing, and recyclable Eucommia gum shape-memory elastomer, including:

[0054] (1) Dissolve 10 g of eucommia gum in organic solvent xylene to make a 5% solution, add 10 mmol of formic acid and 30 mmol of peracetic acid, react at 40° C. for 5 hours, precipitate, wash, and dry to obtain the product A modified eucommia glue;

[0055] (2) 10g product A modified eucommia gum, 3g eucommia gum, 0.15g glutaric acid, 0.25g imidazole, 0.1g zinc sulfate are dissolved in xylene, fully mixed;

[0056] Precipitate with organic solvent ethanol, wash, dry, and finally vulcanize at 170°C and 15MPa for 30 minutes to obtain the shape memory elastomer of Eucommia gum.

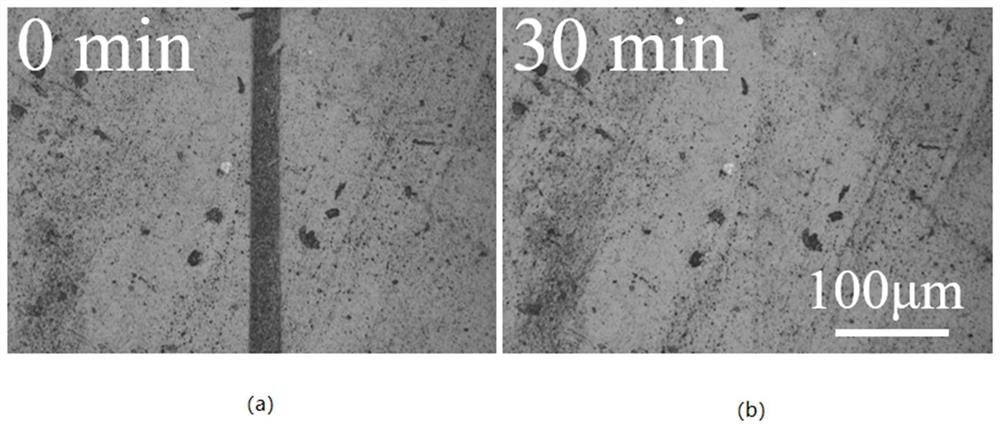

[0057] Such as figure 2 As shown, use a razor blade to make a scratch on the surface of the sample, such as figure 2 As shown in (a); and the sample was placed in a 120°C oven for 30 minutes of self-repair, and the scratches basically disappea...

Embodiment 3

[0059] This embodiment provides a method for preparing a self-reinforcing, self-repairing, and recyclable Eucommia gum shape-memory elastomer, including:

[0060] (1) Dissolve 10 g of eucommia gum in the organic solvent chloroform to make a 2% solution, add 10 mmol of benzoic acid and 35 mmol of hydrogen peroxide, react at 50 ° C for 4 hours, and obtain the product A modified eucommia by precipitation, washing and drying glue;

[0061] (2) Dissolve 10 g of product A modified eucommia gum, 0.5 g of eucommia gum, 0.05 g of ethylenediamine, 0.05 oxalic acid, 0.1 g of tetrabutylammonium chloride, and 0.1 g of zinc sulfate in chloroform, and mix thoroughly;

[0062] Precipitate with organic solvent methanol, wash, dry, and finally vulcanize at 180°C and 10MPa for 25 minutes to obtain the shape memory elastomer of Eucommia gum.

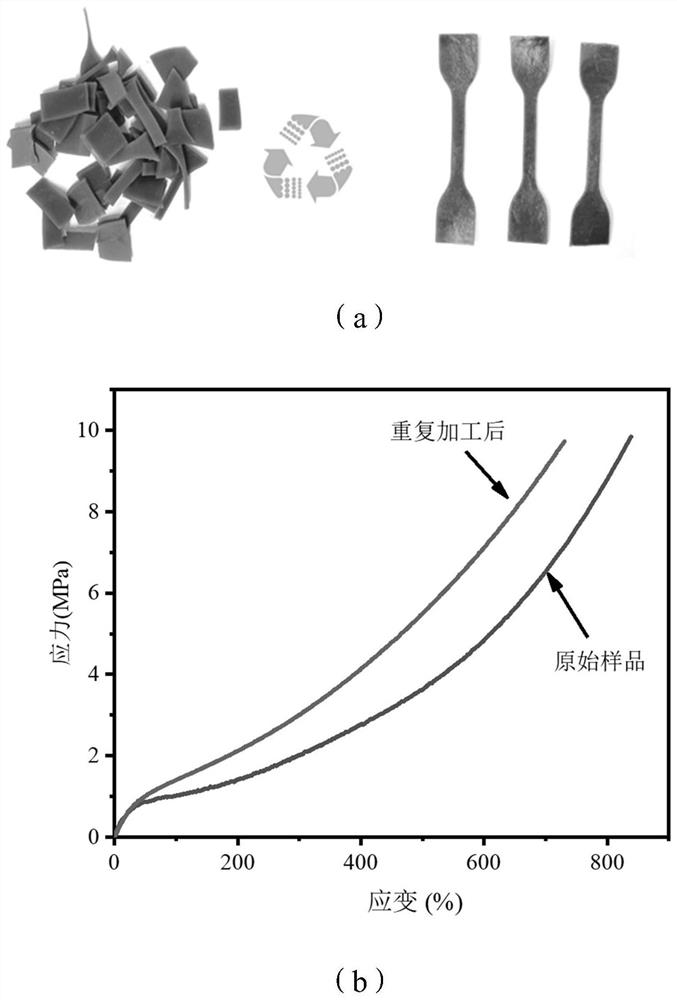

[0063] Such as image 3 As shown in (a), cut the prepared original sample Eucommia gum shape memory elastomer into pieces, as shown in the left figure, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap