Degradable bio-based polyester as well as preparation method, degradation method and application thereof

A technology based on polyester and biotechnology, applied in the field of bio-based polyester and its preparation, can solve the problems of single degradation mechanism and slow degradation rate, and achieve the effects of rapid degradation, excellent mechanical properties and thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention also provides a kind of preparation method of described degradable bio-based polyester, comprising:

[0057] S1, itaconic acid or its esterified product, dibasic acid with 3-20 carbon atoms having a ring structure or its esterified product, dihydric alcohol with 2-20 carbon atoms, esterification catalyst, polymerization inhibitor The reagents are mixed and subjected to an esterification reaction to obtain the first intermediate product, wherein the mole of the itaconic acid or its esterified product and the dibasic acid with a ring structure of 3-20 carbon atoms or its esterified product The ratio is 1:1-1:9;

[0058] S2, performing a polycondensation reaction on the first intermediate product to obtain a degradable bio-based polyester.

[0059] The itaconic acid produced by biological fermentation has an aliphatic segment structure, so itaconic acid or its esters can be used to prepare bio-based polyesters, however, due to the poor structural reg...

Embodiment 1

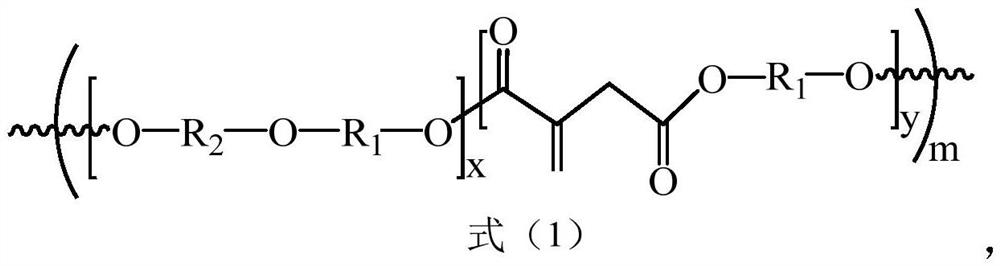

[0088]Add dimethyl terephthalate, dimethyl itaconate, and 1,4-butanediol into the reactor according to the molar ratio of 0.7:0.3:1.6, and then add dimethyl terephthalate in a molar amount of 4‰ The esterification catalyst anhydrous zinc acetate and 10‰ polymerization inhibitor p-hydroxyanisole, under the condition of nitrogen protection, the temperature was gradually raised to 170°C for esterification reaction for 3 hours, and then the molar amount of dimethyl terephthalate was added 5.0‰ polycondensation catalyst antimony trioxide and 3.0‰ stabilizer trimethyl phosphate, gradually increase the temperature to 210°C, gradually reduce the vacuum degree to 10Pa, and react for 3 hours to obtain polybutylene terephthalic acid / itaconate Ester, its structure is as shown in formula (1-1):

[0089]

[0090] Wherein, x, y, and m are all integers, x=1-10, y=1-10, m=20-100.

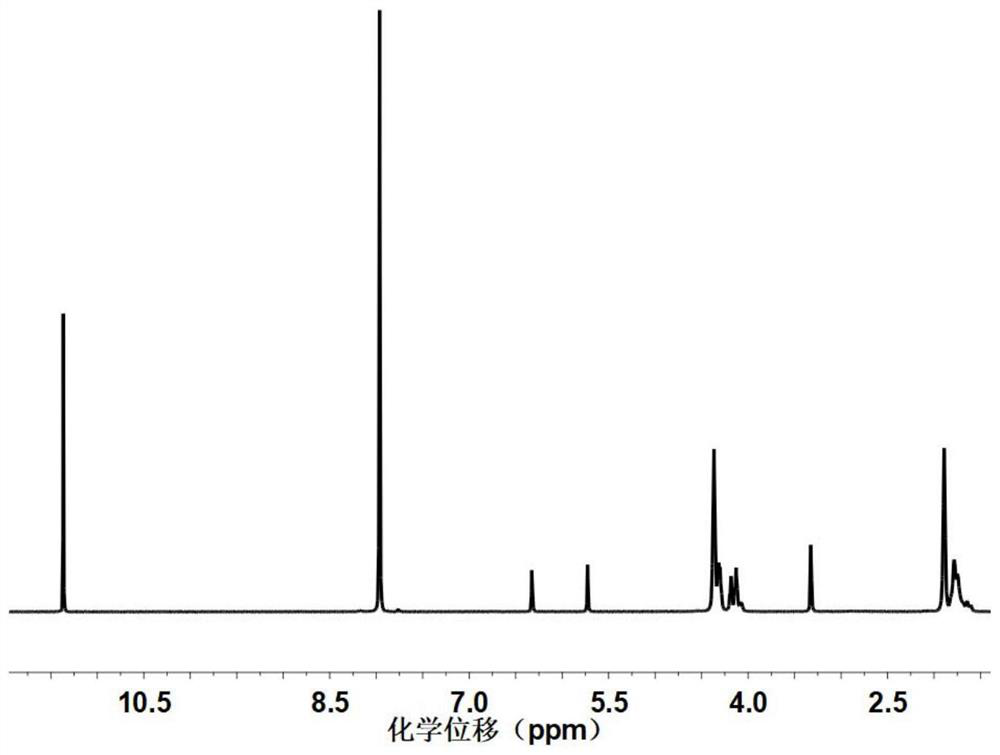

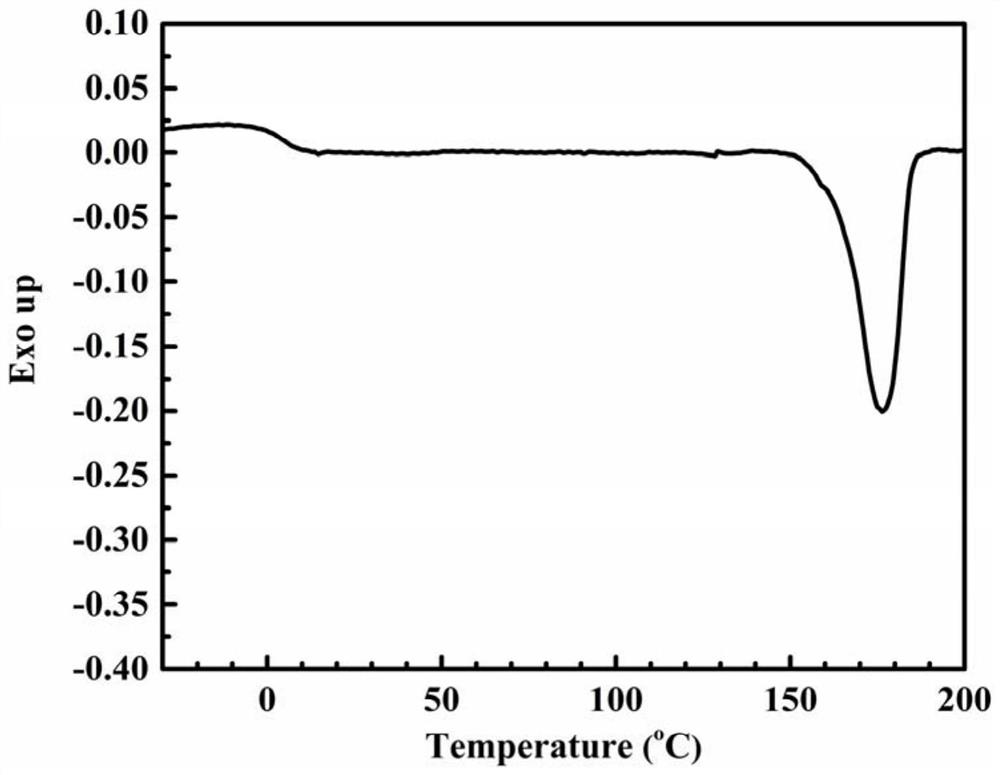

[0091] The polybutylene terephthalate / itaconate was subjected to tests such as proton nuclear magnetic resona...

Embodiment 2

[0096] Add dimethyl 2,5-furandicarboxylate, itaconic acid, and neopentyl glycol into the reactor in a molar ratio of 0.7:0.3:1.4, and then add dimethyl 2,5-furandicarboxylate in a molar amount of 4‰ The esterification catalyst is anhydrous zinc acetate and 6‰ polymerization inhibitor hydroquinone, under the condition of nitrogen protection, the temperature is gradually raised to 165°C for esterification reaction for 4 hours, and then dimethyl 2,5-furandicarboxylate is added The polycondensation catalyst dibutyl tin oxide with a molar weight of 5.0‰ and the stabilizer trimethyl phosphate of 3.0‰ are gradually heated up to 200°C, the vacuum degree is gradually reduced to 15Pa, and the reaction is carried out for 4 hours to obtain new polyfurandicarboxylic acid / itaconic acid Pentylene glycol ester, its structure is shown in formula (1-2):

[0097]

[0098] Wherein, x, y, and m are all integers, x=1-10, y=1-10, m=20-100.

[0099] It can be seen from the proton nuclear magnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com