Gear oil composition and preparation method thereof

A technology of gear oil and composition, applied in the field of lubricating oil, to achieve the effect of excellent thermal oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0061] Phosphonothioate compound, prepared according to the method of CN 111057107A Example 2

[0062] Nitrogen-containing derivatives of sulfuric acid, Jinzhou Kangtai Lubricating Oil Additive Company, industrial product T561, Beijing Xingpu Fine Chemical Technology Development Co., Ltd., industrial product

[0063] T106, Wuxi South Petroleum Additive Co., Ltd., industrial products

[0064] T706, Nanjing Jinling Chemical Synthetic Reagent Factory, industrial product

[0065]T901, Danyang Tianyu Petroleum Additive Factory, industrial products

[0066] T903, Danyang Tianyu Petroleum Additive Factory, industrial product T534, Beijing Xingpu Fine Chemical Technology Development Co., Ltd., industrial product

[0067] Lubricating base oil E-1 includes 25% of HVI 100SN mineral oil and 75% of HVI 120BS mineral oil, plus 1.0% of T803 and 0.6% of T602 in the total mass of the above mineral oil mixture.

[0068] Lubricating base oil E-2, including 45% HVI 350SN mineral oil and 55% GT...

Embodiment 1

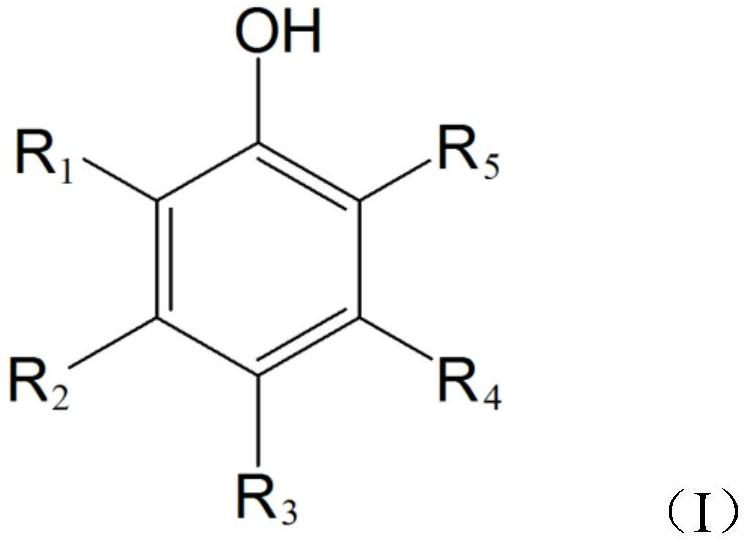

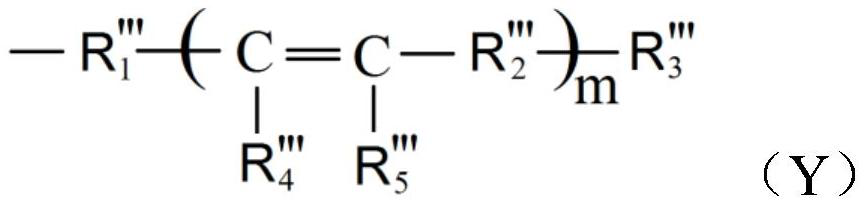

[0073] Example 1 Meta-substituted C 3 ~ 15 Preparation of isomeric alkylphenols

[0074] Put 100g cardanol and 15g isomerization catalyst into a 200ml autoclave, close the autoclave, feed hydrogen to 6MPa, start stirring and heating. The reaction temperature was 320° C., and the reaction was carried out for 5 hours. After the reaction, the temperature was lowered to 60°C, and the yellow liquid reaction mixture was taken out, and distilled under reduced pressure at 100 Pa and 160°C for 1 hour, and the meta-substituted C with a purity of more than 98% was obtained after cooling. 3 ~C 15 isomeric alkylphenols. The reaction conversion rate was 95.6%. An example reaction equation is as follows:

[0075]

[0076] Example 2 Meta-substituted C 3 ~C 15 Preparation of isomeric alkylphenols

[0077] Put 100g cardanol and 3g isomerization catalyst into a 200ml autoclave, close the autoclave, feed hydrogen to 18MPa, start stirring and heating. The temperature was 420°C, and th...

Embodiment 3

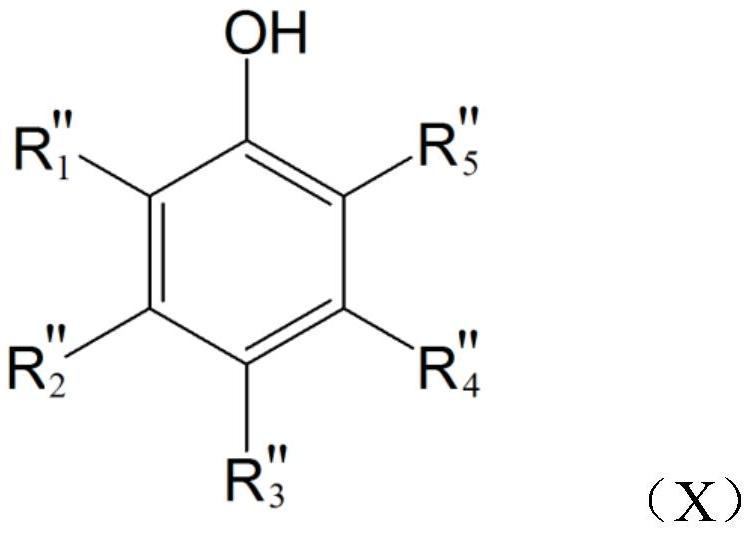

[0078] Example 3 Preparation of 3-isomeric alkyl-6-tert-butylphenol

[0079] Dissolve 30 g of the product of Example 1 into 100 ml of cyclohexane, put it into a 250 ml three-neck reaction flask after dissolving, add 1.5 g of zinc chloride catalyst, start stirring and heating. Maintaining the reaction temperature at 50°C, 9.5 g of tert-butyl chloride was slowly added dropwise into the reaction flask, and the reaction was continued for 5 hours after the dropwise addition was completed. After the reaction, the temperature was lowered to obtain a brown-red transparent liquid. After filtering the reaction product, wash it with 5% KOH solution for alkali, then wash it with distilled water to neutrality, distill under reduced pressure at 1000Pa and 120°C for 1h, remove the solvent, water and unreacted raw materials, and obtain a brown-yellow liquid after cooling down . Product conversion was 81.3%. An example reaction equation is as follows:

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com