Parallel treatment device and method for flue gas of garbage furnace and coal-fired furnace

A treatment device and coal-fired furnace technology, applied in the direction of combustion method, combustion product treatment, incinerator, etc., can solve the high chlorine corrosion hazard of combustion temperature level, limit the amount of solid waste mixed combustion of coal-fired boilers, and extend the original investment cycle and other issues, to avoid comprehensive utilization, shorten the construction cycle, and reduce the original investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

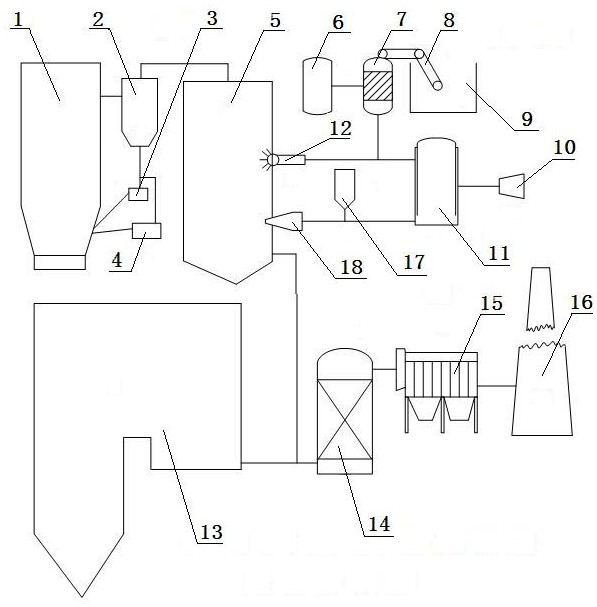

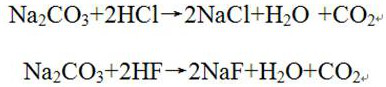

[0023] A parallel treatment device for flue gas from a garbage furnace and a coal-fired furnace, which comprises: a solid waste furnace 1, the flue gas port of the solid waste furnace is connected to a separator 2, and the hot ash port of the separator is respectively connected to the return material The separator 3 and the external bed 4 are connected, the flue gas port of the separator is connected with the tail flue 5, and the outlet of the tail flue is respectively connected with the coal-fired furnace 13 and the desulfurization tower 14, and the tail flue is respectively installed with Sprayer 12, injector 18, described sprayer is connected with lye tank 7, gas storage tank 11 respectively, described lye tank is connected with soda ash storehouse 9 by conveyor 8, described lye tank is connected with soft water tank 6 connected, the injectors are respectively connected with the activated carbon bin 17 and the air storage tank, and the air storage tank is connected with the ...

Embodiment 2

[0025] According to the waste gas furnace and coal-fired furnace flue gas parallel processing device described in embodiment 1, the described return device and the external bed are respectively connected to the return port of the solid waste furnace, and the described desulfurization tower and Dust collector 15 is connected, and described dust collector is connected with chimney 16.

Embodiment 3

[0027] According to the treatment method of the garbage furnace and coal-fired furnace flue gas parallel treatment device described in embodiment 1 or 2, the method comprises the following steps:

[0028] First, the solid waste is incinerated in the solid waste furnace, and the flue gas generated enters the separator through the flue gas port set by the solid waste furnace to separate the flue gas from the larger particle fly ash. The separator is also equipped with a hot ash port and a flue gas The air port, the separated fly ash enters the feeder and the external bed respectively from the hot ash port, and a high-temperature heating surface is set in the feeder, and the hot ash exchanges heat with the steam to increase the steam temperature, thereby improving the boiler efficiency, and the feeder Connect the solid waste furnace with the outlet of the external bed and set a return port. After the hot ash stays in the return device and the external bed for a certain period of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com