Preparation method for continuously growing tungsten selenide film through MOCVD

A tungsten selenide and thin film technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of increasing selenium atom desorption, reducing nucleation density, reducing crystal quality, etc., to promote epitaxial growth, avoid Carbon pollution, effects of controlling nucleation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

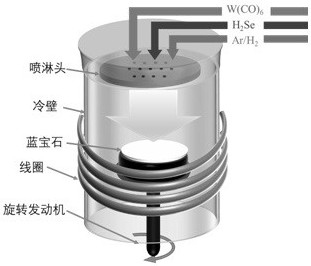

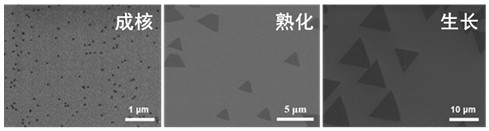

[0022] A method proposed in this embodiment uses MOCVD to continuously grow high-quality two-dimensional semiconductor thin films (WSe 2 ) preparation method, which comprises the following steps:

[0023] Step 1: cleaning the c-plane sapphire substrate;

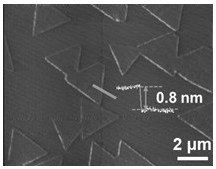

[0024] Step 2: Put the cleaned substrate into the MOCVD reaction chamber, perform high-temperature pretreatment on the substrate, and then use tungsten hexacarbonyl (W(CO) 6 ) and hydrogen selenide (H 2 Se) is used as a precursor, and WSe is deposited on sapphire by continuous growth of MOCVD 2 film;

[0025] Step 3: WSe grown on sapphire 2 After the film is annealed, a continuous, large-area and high-quality crystalline finished product is obtained. Annealed at 400°C in hydrogen (H 2 ) and argon (Ar) mixed atmosphere for 2 hours, and the heating and cooling rate during the annealing process is 40°C / hour.

[0026] The specific process of step 1 is: immerse the sapphire substrate in acetone, sonicate it for 10 minutes, ...

Embodiment 2

[0033] A method proposed in this embodiment uses MOCVD to continuously grow high-quality two-dimensional semiconductor thin films (WSe 2 ) preparation method, which comprises the following steps:

[0034] Step 1: cleaning the c-plane sapphire substrate;

[0035] Step 2: Put the cleaned substrate into the MOCVD reaction chamber, perform high-temperature pretreatment on the substrate, and then use tungsten hexacarbonyl (W(CO) 6 ) and hydrogen selenide (H 2 Se) is used as a precursor, and WSe is deposited on sapphire by continuous growth of MOCVD 2 film;

[0036] Step 3: WSe grown on sapphire 2 After the film is annealed, a continuous, large-area and high-quality crystalline finished product is obtained. Annealed at 400°C in hydrogen (H 2 ) and argon (Ar) mixed atmosphere for 2 hours, and the heating and cooling rate during the annealing process is 40°C / hour.

[0037] The specific process of step 1 is as follows: immerse the sapphire substrate in acetone, ultrasonically tr...

Embodiment 3

[0044] A method proposed in this embodiment uses MOCVD to continuously grow high-quality two-dimensional semiconductor thin films (WSe 2 ) preparation method, which comprises the following steps:

[0045] Step 1: cleaning the c-plane sapphire substrate;

[0046] Step 2: Put the cleaned substrate into the MOCVD reaction chamber, perform high-temperature pretreatment on the substrate, and then use tungsten hexacarbonyl (W(CO) 6 ) and hydrogen selenide (H 2 Se) is used as a precursor, and WSe is deposited on sapphire by continuous growth of MOCVD 2 film;

[0047] Step 3: WSe grown on sapphire 2 After the film is annealed, a continuous, large-area and high-quality crystalline finished product is obtained. Annealed at 400°C in hydrogen (H 2 ) and argon (Ar) mixed atmosphere for 2 hours, and the heating and cooling rate during the annealing process is 40°C / hour.

[0048] The specific process of step 1 is as follows: immerse the sapphire substrate in acetone, ultrasonically tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com