High-stability nano platinum-based intermetallic compound direct methanol fuel cell electrocatalyst and preparation method thereof

A methanol fuel cell and electrocatalyst technology, applied in battery electrodes, nanotechnology, nanotechnology and other directions, can solve the problems of complex preparation, growth, easy agglomeration of nanoparticles, and achieve simple and feasible preparation methods, overcome removal difficulties, The effect of inhibiting migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

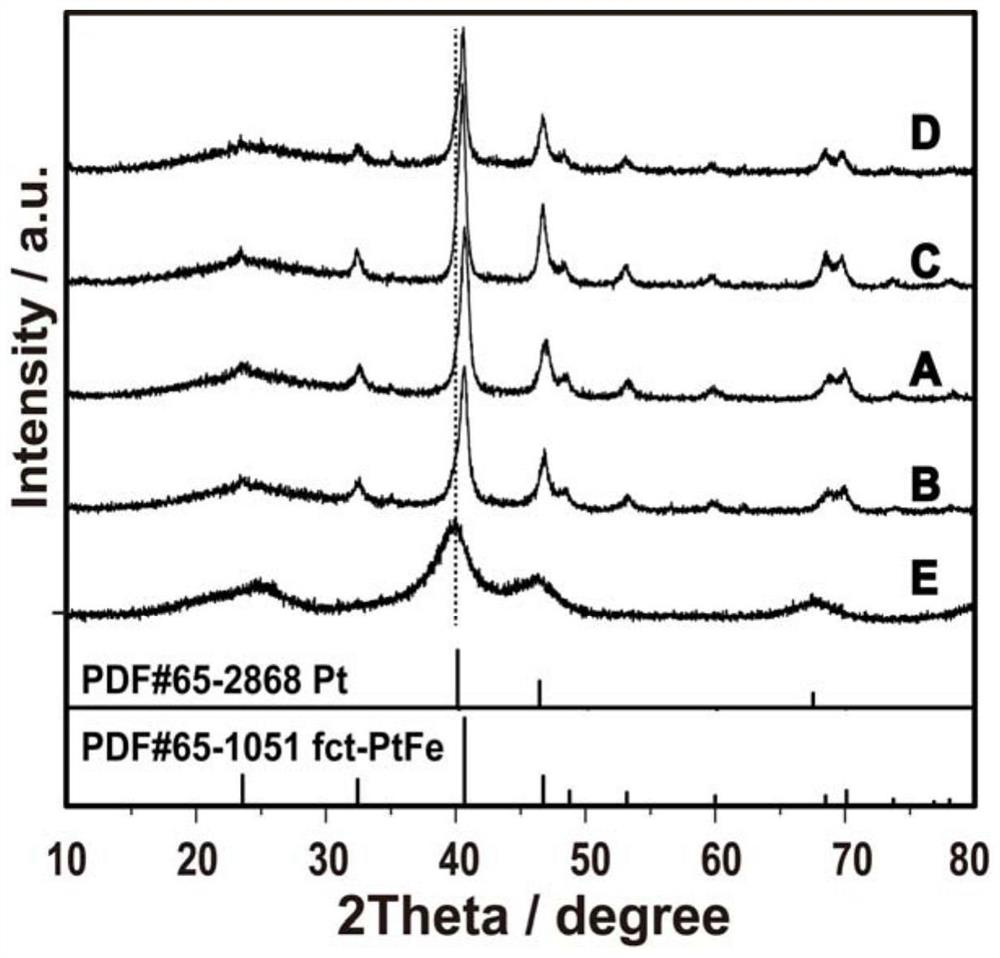

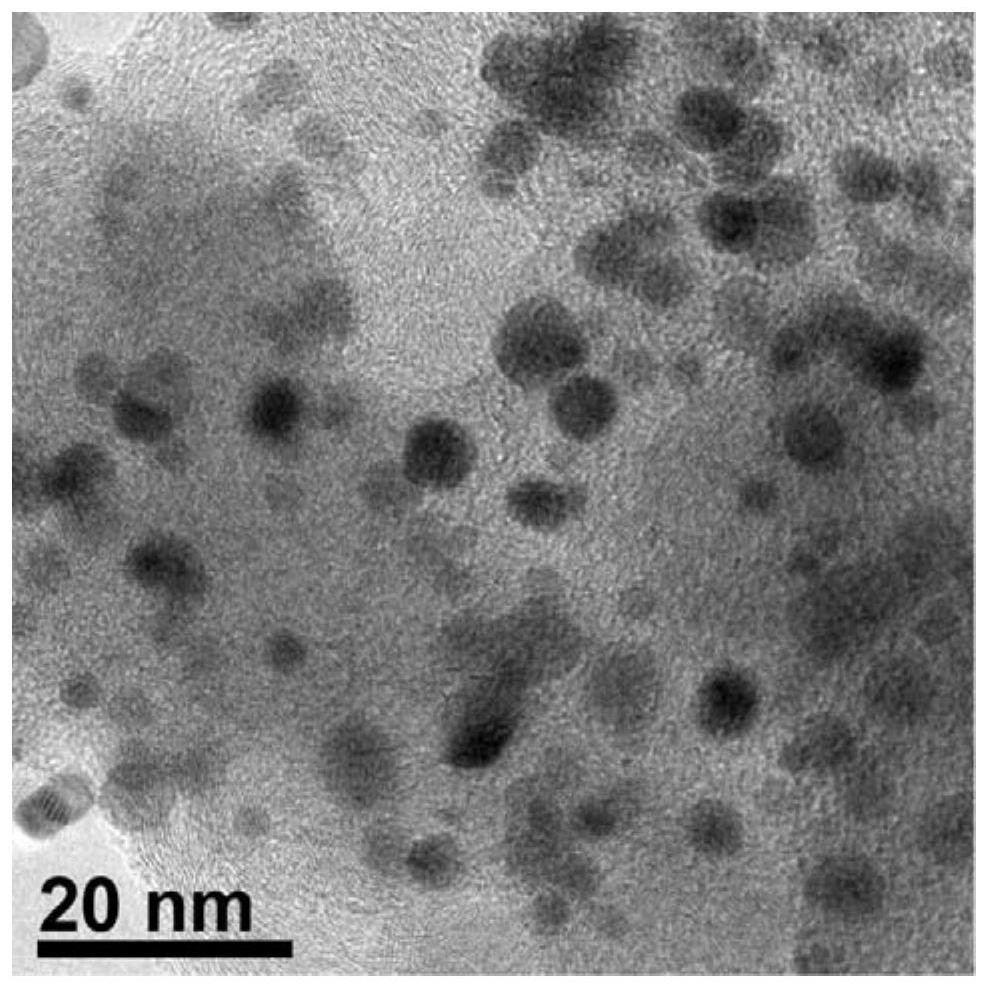

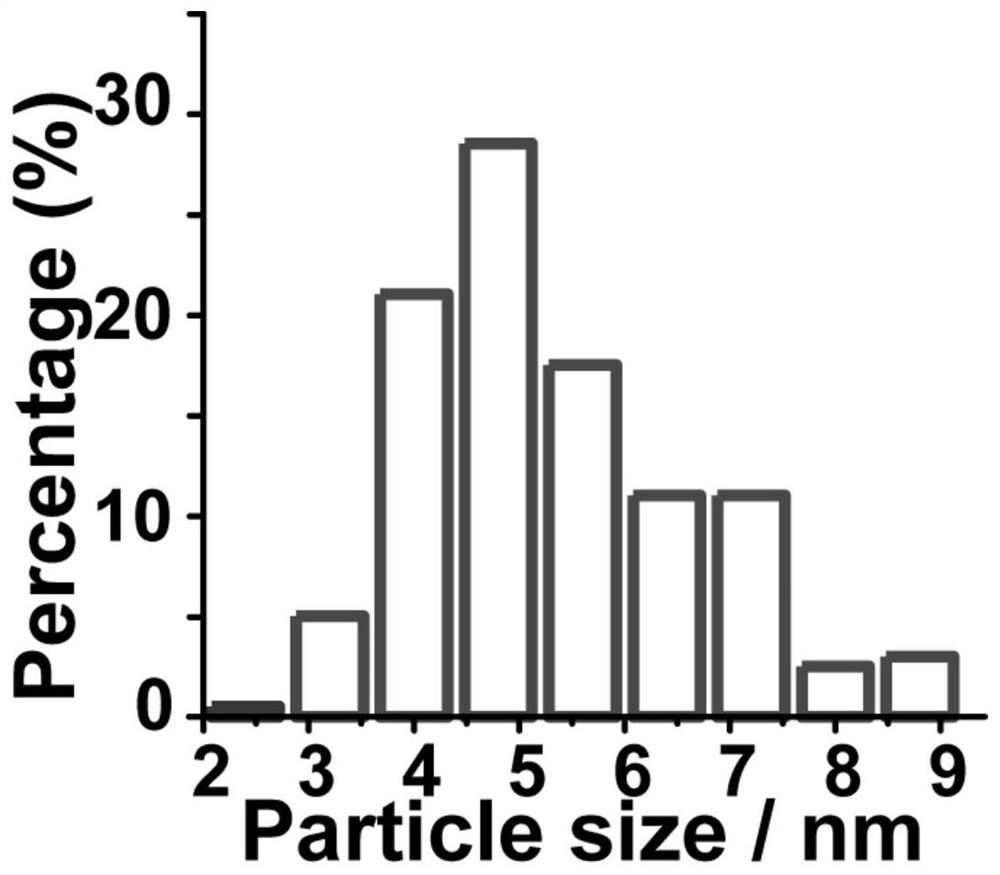

[0050] The purpose of the present invention is to provide a highly stable nano-platinum-based intermetallic compound direct methanol fuel cell electrocatalyst for the shortcomings of the existing intermetallic compound nano-catalyst direct methanol fuel cell electrocatalyst preparation complexity, nano-particles are easy to agglomerate, grow up, etc. A preparation method comprising the steps of:

[0051] First, a layer of polyaniline (PANI) is oxidized and polymerized on the surface of the Pt / C catalyst in situ, and a certain amount of transition metal ions is adsorbed, and then solidified and packaged with an inorganic salt solution to obtain a salt-sealed and cured sample; the salt-sealed solidified Driven by high temperature, the transition metal ions are reduced to transition metal atoms by the reduction of nitrogen-doped carbon (NC) formed by carbonization of polyaniline, and the transition metal atoms gradually diffuse into the Pt lattice to form a Pt-based alloy; Pt At ...

Embodiment 1

[0086] (1), Pt / C catalyst surface coated with polyaniline (PANI)

[0087] Weigh the Pt / C catalyst and aniline according to the mass ratio of Pt / C catalyst:aniline as 1:1, and weigh the ammonium persulfate according to the mass ratio of aniline:ammonium persulfate as 1:3. First add aniline monomer to 0.5mol / L sulfuric acid aqueous solution, after ultrasonic stirring for 20 minutes, add Pt / C catalyst, continue ultrasonic stirring for 20 hours, after the Pt / C catalyst is uniformly dispersed, under the condition of stirring at 0°C, put Ammonium persulfate dissolved in 0.5mol / L sulfuric acid aqueous solution was slowly added dropwise to the mixed solution of Pt / C catalyst and aniline, and the dropping time was controlled at 30 minutes. After the dropping was completed, the reaction was continued for 24 hours; then the product was dried and ground to obtain a polyaniline-coated Pt / C catalyst (PANI@Pt / C).

[0088] (2), metal iron salt adsorption and inorganic salt solution recrystal...

Embodiment 2

[0103] (1), Pt / C catalyst surface coated with polyaniline (PANI)

[0104] Weigh the Pt / C catalyst and aniline according to the mass ratio of Pt / C catalyst:aniline as 1:1, and weigh the ammonium persulfate according to the mass ratio of aniline:ammonium persulfate as 1:3. First add aniline monomer to 0.5mol / L sulfuric acid aqueous solution, after ultrasonic stirring for 20 minutes, add Pt / C catalyst, continue ultrasonic stirring for 20 hours, after the Pt / C catalyst is uniformly dispersed, under the condition of stirring at 0°C, put Ammonium persulfate dissolved in 0.5mol / L sulfuric acid aqueous solution was slowly added dropwise to the mixed solution of Pt / C catalyst and aniline, and the dropping time was controlled at 30 minutes. After the dropping was completed, the reaction was continued for 20 hours; then the product was dried and ground to obtain a polyaniline-coated Pt / C catalyst (PANI@Pt / C).

[0105] (2), metal iron salt adsorption and inorganic salt solution recrystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com