Rapid preparation method of boron nitride/carbon nitride/silver monatomic antibacterial agent

A technology of carbon nitride and boron nitride, which is applied in the field of nanomaterial preparation, can solve the problem of low efficiency in killing bacteria and viruses, and achieve the effects of high antibacterial and antiviral efficiency, simple operation, and improved antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

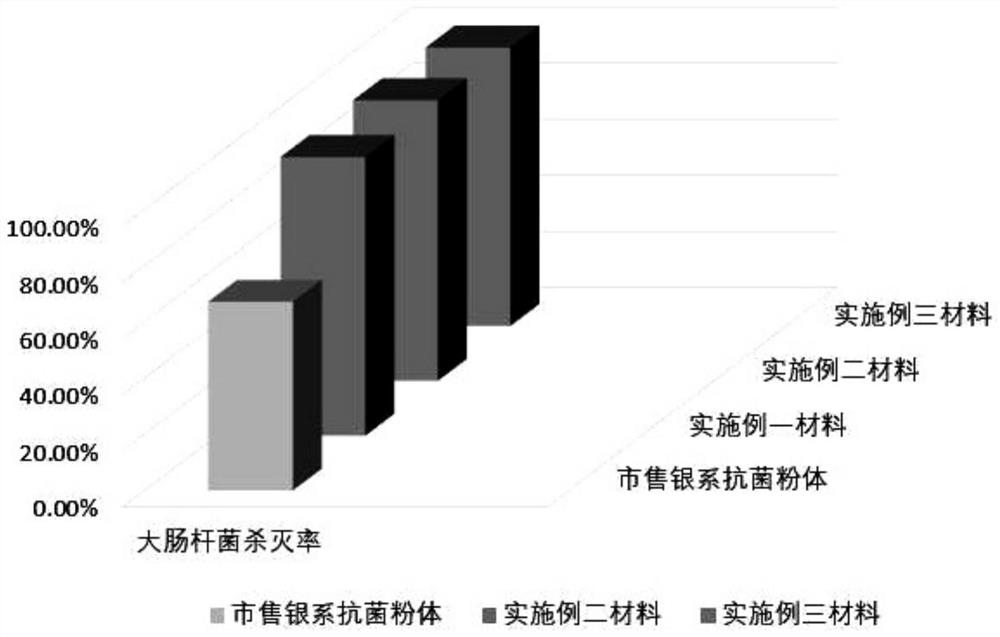

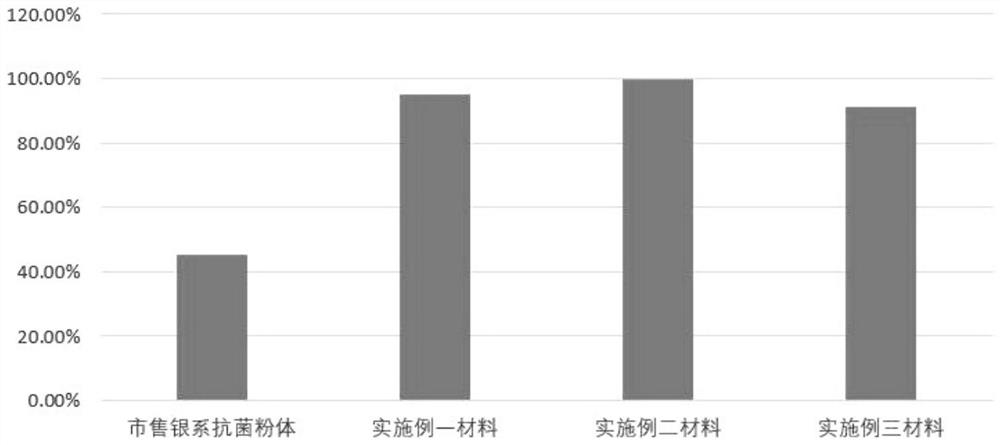

Embodiment 1

[0022] Accurately weigh the nitrogen source, boron source, and carbon sources (nitrogen source is melamine; boron source is boric acid; carbon source is chitosan; the mass ratio of nitrogen source and boron sources is 1: 1; nitrogen source and carbon source mass ratio In a 1: 0.5), first put it into a beaker and add a solvent (the solvent is water; the mass ratio of the nitrogen source and the solvent is 1: 100) makes it fully dissolved, then add it to the supercritical reactor, and passed The high pressure pump is inserted into the carbon dioxide gas, and the pressure is maintained at a certain temperature (40 ° C) and a certain pressure (100 bar) for a certain amount of time (12h); after the reaction is completely stressed by ultrafine nozzles, through the RESS (supercritical fluid fast expansion) The method was prepared by the boron nitride / carbon nitride heterojunction precursor. After drying it, put it into the ceramic crucible and cover the cover, and then heat (the temper...

Embodiment 2

[0024] Accurately weigh the nitrogen source, boron source, and carbon source (nitrogen source is urea; boron source is borax; carbon source is sucrose; the mass ratio of nitrogen source and boron source is 1: 0.2; nitrogen source and carbon source mass ratio 1 : 2), first put it into a beaker and add a solvent (solvent is ethanol; the mass ratio of nitrogen source and solvent is 1: 200), which is sufficiently dissolved, then add it to the supercritical reactor, and passes through the high pressure pump The carbon dioxide gas is introduced, and the pressure is maintained at a certain temperature (60 ° C) and a certain pressure (200 bar). After a certain amount of pressure (5h); after the reaction is completed, the pressure is quickly charged by ultrafine nozzles, through the RESS (supercritical fluid fast expansion) method. The boron nitride / carbon nitride heterojunction precursor was prepared. After drying it, placed in a ceramic crucible and covered a cover, and then heat (heat...

Embodiment 3

[0026] Accurately weigh the nitrogen source, boron source, and carbon sources (nitrogen source is monanlam; boron source is sodium borate; the carbon source is a phenolic resin; the mass ratio of nitrogen source and boron is 1: 1; nitrogen source and carbon source The mass ratio is 1: 0.5), first put it into the beaker and add solvent (solvent is propionate; the mass ratio of nitrogen source and solvent is 1: 500) make it fully dissolved, then add it to supercritical reactor In the middle, and the carbon dioxide gas is introduced by the high pressure pump, and the pressure is maintained at a certain temperature (80 ° C) and a certain pressure (150 bar); 56h); after the reaction is completed, quickly vent pressure through the ultrafine nozzle, through RESS (super Rapid expansion of critical fluids) A boron nitride / carbon nitride heterojunction precursor was prepared. After drying it, placed in a ceramic crucible and covered a cover, and then heat (temperature rate of 3 ° C / min)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com