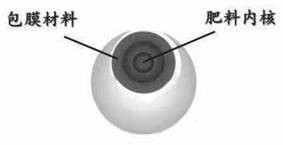

A kind of preparation method of lignin-based water-retaining double-layer slow-controlled release fertilizer

A technology of lignin-based, controlled-release fertilizers, applied in layered/coated fertilizers, fertilizer mixtures, solid/semi-solid fertilizers, etc., can solve the problem of fast nutrient release, high cost of coating materials, and materials that are too hydrophilic and other problems, to achieve the effect of simple operation, improved water absorption and water retention capacity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

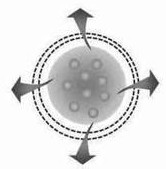

[0022] The invention is a preparation method of a lignin-based water-retaining slow-controlled release fertilizer, the steps of which are as follows:

[0023] Step (1) Preparation of the blended solution of polyvinyl alcohol and cellulose derivatives: Connect a condenser tube and a mechanical stirrer in the reaction vessel, add 1-6g of polyvinyl alcohol and 100-200 mL of distilled water, and raise the temperature of the water bath to 90-95 ℃, stir and keep warm for 1 hour until it is completely dissolved, and a 1-6% concentration of polyvinyl alcohol solution is obtained. Cool the system down to 50-60°C, stir quickly and add 0.5-2g of cellulose derivatives, and stir at this temperature for 30 minutes to obtain a blend solution of polyvinyl alcohol and cellulose derivatives with a concentration of 1-6%;

[0024] The pure polyvinyl alcohol solution prepared in step (2) is compared with the solution obtained in step (1);

[0025] Step (3) Preparation of lignin-based solution: fi...

Embodiment 1

[0042] Embodiment 1: preparation method, comprises the following steps:

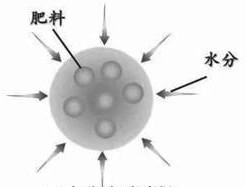

[0043] ①Inner coating: by mass parts, mechanically stir 1g of polyvinyl alcohol and 100ml of aqueous solution at 85°C at a speed of 200r / min and keep warm for 1h. Lower the temperature to 45°C, increase the rotation speed to 300r / min, add 0.5g of ethyl cellulose and stir rapidly for 30min to obtain a blended solution for later use;

[0044] ②Outer coating: Dissolve 0.25g of sodium lignosulfonate in 100ml of sodium hydroxide solution (1 mol / L) to obtain a lignin-based solution. 4.0 g of acrylic acid, 4.0 g of acrylamide and 0.31 g of N,N' methylenebisacrylamide were dissolved in 30 mL of distilled water to obtain a mixed solution. The above solution was ultrasonically oscillated at a frequency of 50 MHz for 40 min, 0.8 g of attapulgite (ATP) was added to the lignin-based solution, and then the mixed solution was added to the lignin-based solution. After the system was uniformly dispersed, HCl was added ...

Embodiment 2

[0047] Embodiment 2: preparation method, comprises the following steps:

[0048] ①Inner coating: by mass parts, mechanically stir 3.5g of polyhydroxybutyrate and 50ml of chloroform at 95°C at a speed of 500r / min and keep warm for 3h. Lower the temperature to 55°C, reduce the rotational speed to 330r / min, add 0.75g of cellulose acetate butyrate and stir rapidly for 40min to obtain a blended solution for later use;

[0049] ② Outer coating: Dissolve 0.75g of calcium lignosulfonate in 150ml of sodium hydroxide solution (1 mol / L) to obtain a lignin-based solution. 5.0 g of acrylic acid, 5.0 g of acrylamide and 0.45 g of N,N' methylenebisacrylamide were dissolved in 25 mL of distilled water to obtain a mixed solution. The above solution was ultrasonically oscillated at a frequency of 60 MHz for 30 minutes, 1.0 g of attapulgite (ATP) was added to the lignin-based solution, and then the mixed solution was added to the lignin-based solution. After the system was uniformly dispersed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com