Oxide near-infrared light-emitting material, preparation method thereof and light-emitting device

A technology for light-emitting materials and light-emitting devices, which can be applied to light-emitting materials, chemical instruments and methods, semiconductor devices, etc., can solve problems such as unstable emission spectra, and achieve the effects of wide excitation and emission ranges, low equipment cost, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

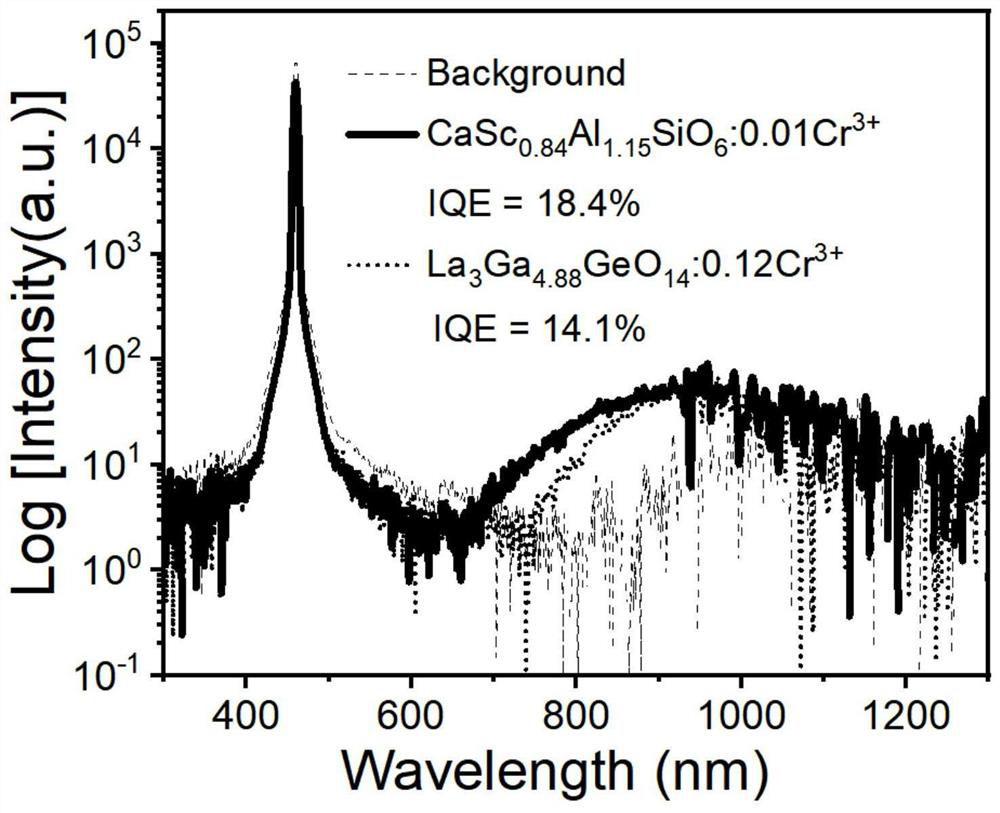

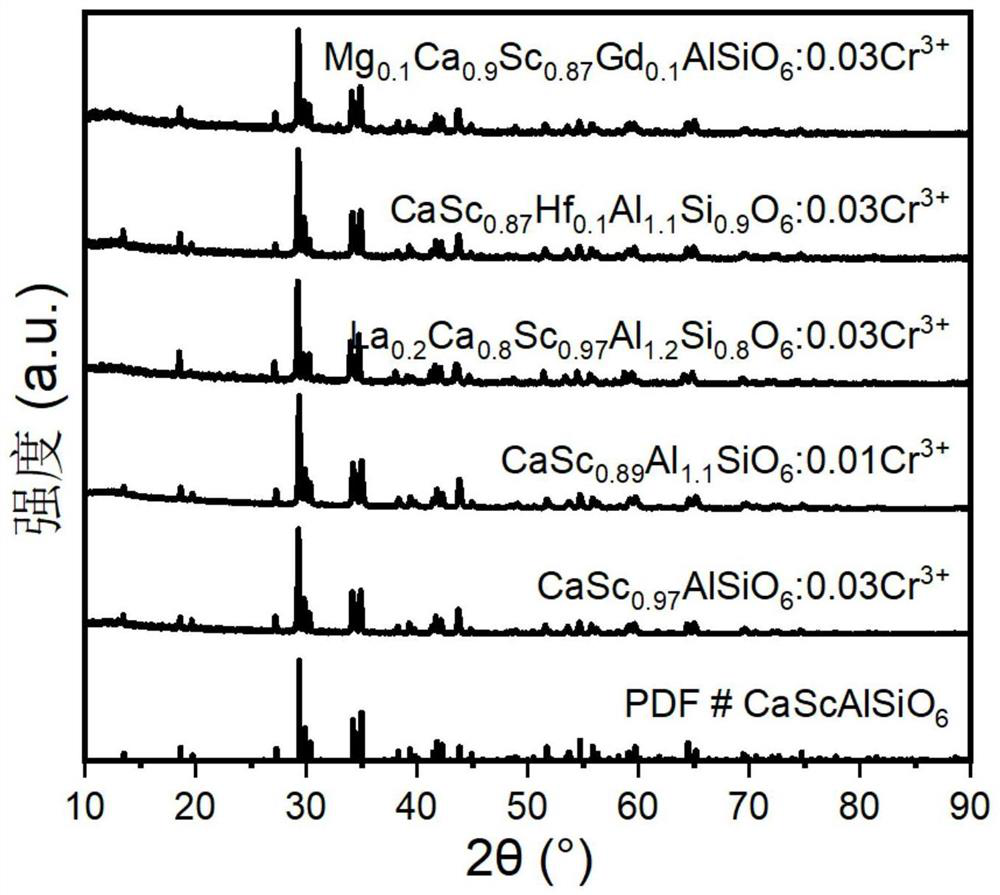

[0048] The chemical composition formula of the near-infrared fluorescent powder of this embodiment is Cr x CaS 1-x AlSiO 6 , where x=0.03. According to the stoichiometric ratio of each element in the chemical formula, accurately weigh Li 2 CO 3 ,CaCO 3 ,Sc 2 o 3 ,Al 2 o 3 , SiO 2 ,Cr 2 o 3 High-purity powder raw materials are placed in an agate mortar and ground for about 30 minutes to fully mix the raw materials evenly. Transfer the mixed raw materials to an alumina crucible, cover and place in 20% H 2 +80%N 2 Sinter at 1500°C for 8 hours in an atmosphere high-temperature reaction furnace, take it out after natural cooling, and grind again for about 10 minutes to obtain Cr 0.03 CaS 0.97 AlSiO 6 Phosphor powder, its XRD and fluorescence spectra are as follows image 3 and Figure 4 shown, from image 3 It can be seen that the phosphor is a single phase, from Figure 4 It can be seen that the phosphor can perfectly match the 460nm blue light chip, and emit n...

Embodiment 2-20

[0052] The chemical composition formula, calcination temperature, time and grinding time of Examples 2-20 are shown in Table 1; refer to Example 1 for the preparation method.

[0053] The XRD of the near-infrared fluorescent material prepared in Examples 1, 8, 12, 14 and 16 and the comparison chart of the standard card are shown in image 3 , it can be seen from the figure that the prepared phosphor is a single phase, and the phosphor obtained in other embodiments is also a single phase;

Embodiment 2

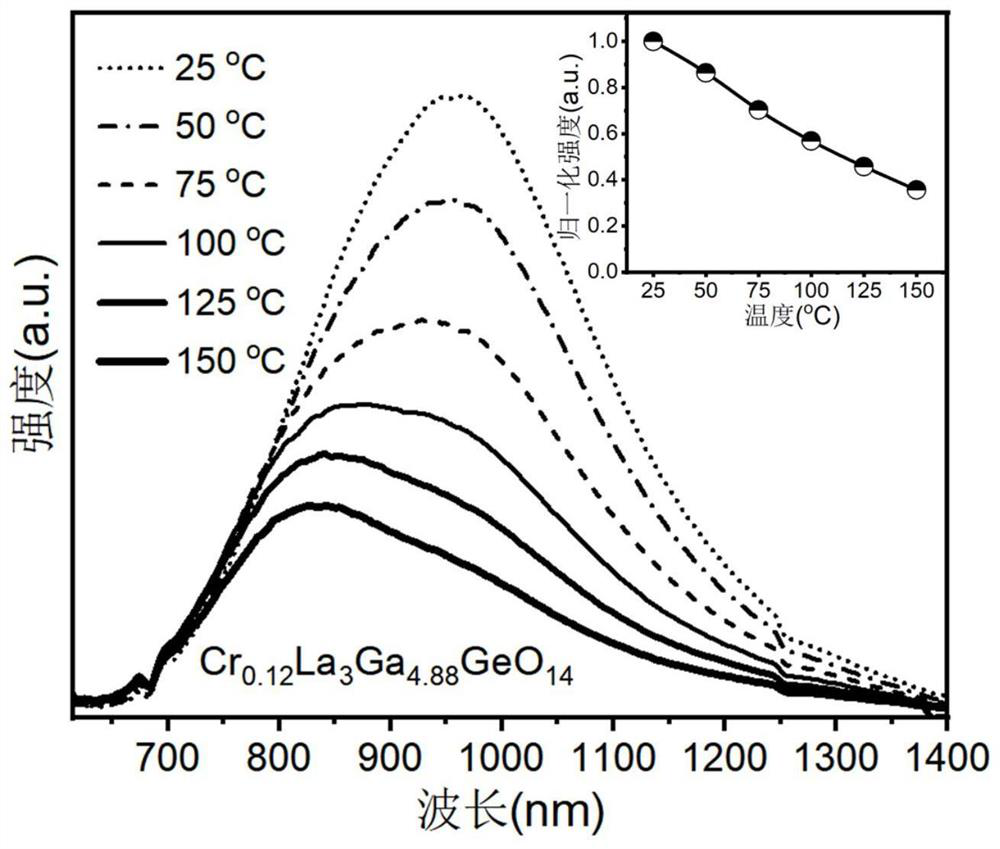

[0054] The Cr prepared by embodiment 2 0.01 CaS 0.84 al 1.15 SiO 6 The fluorescence thermal stability test chart of Figure 5 , it can be seen from the figure that the stability of the phosphor is good, and the luminous intensity at 100°C and 150°C is 69% and 44% of that at room temperature, respectively;

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com