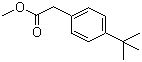

Production method of methyl p-tert-butylphenylacetate

A technology of tert-butylbenzene and methyl acetate, applied in the field of food additive production, can solve the problems of large residues of tert-butyl phenylacetic acid, unreasonable process design, increase of factory cost, etc., so as to shorten the reaction time, improve the product quality, The effect of increasing conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

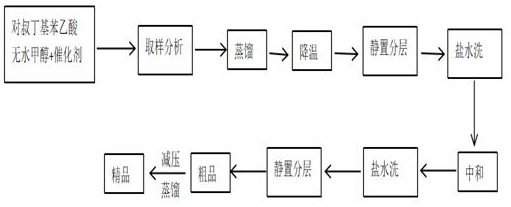

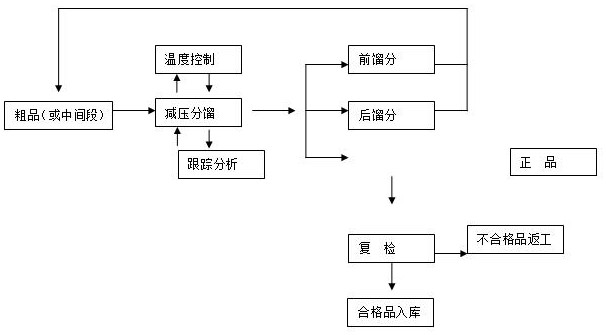

[0031] Method for preparing - methyl tert-butylbenzoacetate: anhydrous methanol and a starting material for t-butyl phytic acid as a starting material, a catalyst for trifluoromethanesulfonic acid, and is prepared by the following reaction operation. Methyl ester:

[0032] 1) Take 1000 ml of three bottles, add anhydrous methanol 300g and 200g of t-butyl phytic acid, catalyst 2G, add, heated reflux reaction, 4 hours, sampling analysis, control to tert-butyl phytic acid ≤ 0.1%, reflow reaction Finish.

[0033] 2) After the reaction is completed, the stream is changed to distillation, and the methanol is recovered at normal pressure to the bottom temperature 80 ° C, and the recovery of 240 g.

[0034] 3) Cooling, standing in layers, removes the lower acid water, the upper organic phase is washed once with 100 g of saturated salt water, and then the organic phase is neutralized with a pure alkaline solution and to pH = 7 ~ 8, then use saturated brine 50 ml × 3 wash To neutral. The cru...

Embodiment 2

[0037] Method for preparation of methyl ester of t-butyl phytate: anhydrous methanol and a starting material for t-butyl phenylacetic acid, trifluoromethanesulfonic acid is a catalyst, and is prepared by the following reaction operation. Phenylacetate:

[0038] 1) Take 1000 ml of three bottles, add 300g of anhydrous methanol and 200g of t-butyl phytic acid, 3G, addition, heating reflow reaction for 4 hours, sampling analysis, control to tert-butyl phytic acid ≤ 0.1%, reflow reaction 5.5 In the end, the reflow reaction ended.

[0039] 2) After the reaction is completed, the stream is changed to distillation, and the methanol is recovered at normal pressure to the bottom temperature 80 ° C, and the recovery of 240 g.

[0040] 3) Cooling, standing in layers, removes the lower acid water, the upper organic phase is washed once with 100 g of saturated salt water, and then the organic phase is neutralized with a pure alkaline solution and to pH = 7 ~ 8, then use saturated brine 50 ml × ...

Embodiment 3

[0043] Method for preparation of methyl ester of t-butyl phytate: anhydrous methanol and a starting material for t-butyl phenylacetic acid, trifluoromethanesulfonic acid is a catalyst, and is prepared by the following reaction operation. Phenylacetate:

[0044] 1) Take 1000 ml of three bottles, add 300g of anhydrous methanol and 200g of t-butyl phytate, 4G, addition, heating reflux for 4 hours, sampling analysis, control to tert-butyl phytic acid ≤ 0.1%, reflow reaction 5.3 In the end, the reflow reaction ended.

[0045] 2) After the reaction is completed, the stream is changed to distillation, and the methanol is recovered at normal pressure to the bottom temperature 80 ° C, and the recovery of 240 g.

[0046] 3) Cooling, standing in layers, removes the lower acid water, the upper organic phase is washed once with 100 g of saturated salt water, and then the organic phase is neutralized with a pure alkaline solution and to pH = 7 ~ 8, then use saturated brine 50 ml × 3 wash To neu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com