Al (at) (TiB2+Ti4O7)-PbO2+CeO2 composite anode plate and preparation method thereof

A composite anode and composite plate technology, applied in electrodes, electrolytic coatings, coatings, etc., can solve the problems of metal Al acid resistance, alkali resistance, poor corrosion resistance, etc., and achieve the effects of low cost, wide adaptability and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

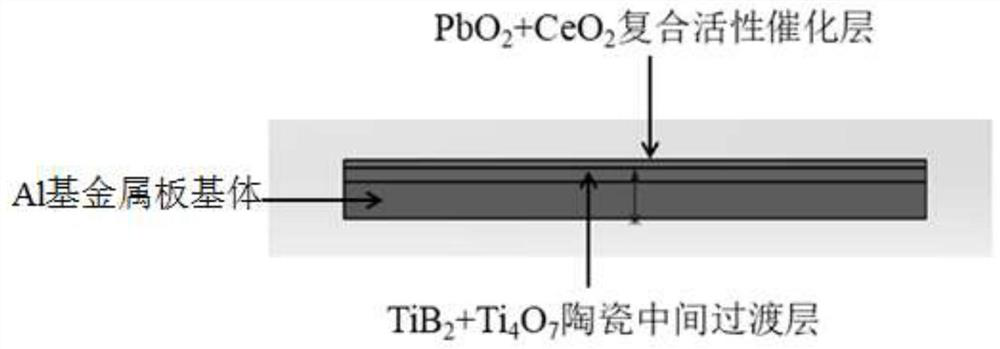

[0026] A kind of core-shell structure Al@(TiB 2 +Ti 4 o 7 )-PbO 2 +CeO 2 Composite anode plates, such as figure 1 As shown, including Al-based metal plate substrate, TiB 2 +Ti 4 o 7 Ceramic interlayer, PbO 2 +CeO 2 Composite active catalytic layer, Al base metal plate is pure Al plate, thickness is 3mm, TiB 2 +Ti 4 o 7 The dusting thickness of the mixed powder is 1mm, and the total thickness of the composite anode plate is 6-8mm. The specific preparation process includes the following steps:

[0027] (1) Pretreatment of Al-based metal plate: Cut an aluminum plate with a thickness of 3 mm into a small sample of 60 mm × 30 mm with a shearing machine, and use a 16 mm benchtop drilling machine to polish the small sample to remove surface oxide film and impurities, and cut the small sample Ultrasonic cleaning in 3% NaOH solution for 2 hours, finally washing with distilled water and drying for later use;

[0028] (2)Al@(TiB 2 +Ti 4 o 7 ) Preparation of layered compos...

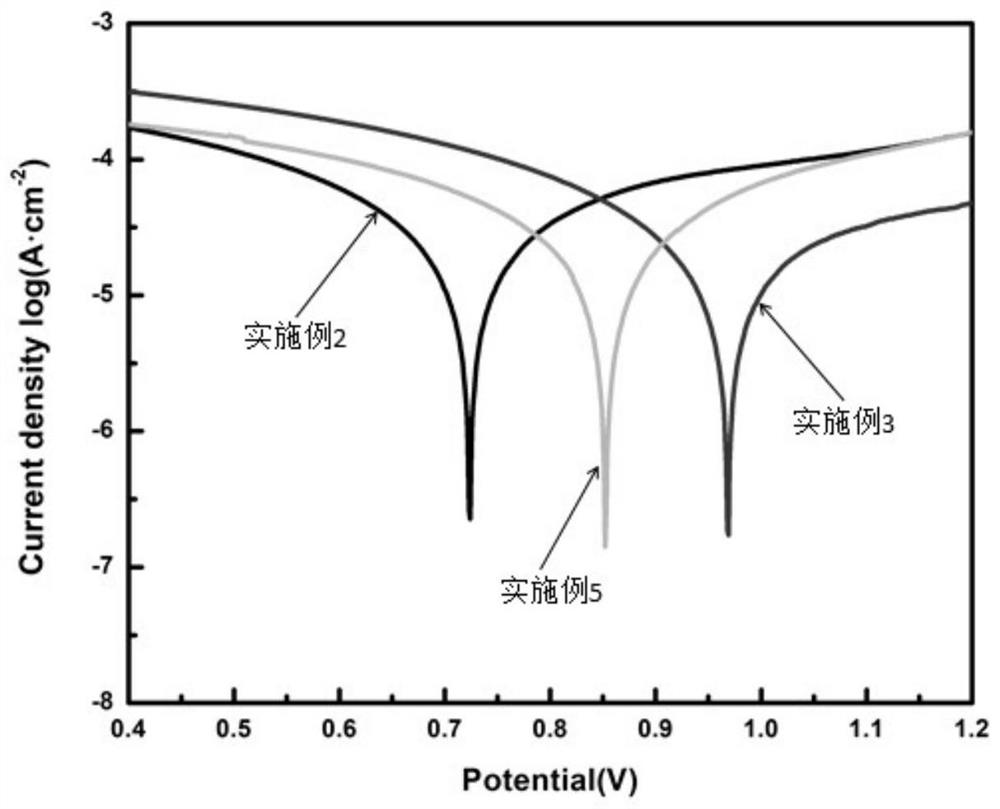

Embodiment 2

[0032] A kind of core-shell structure Al@(TiB 2 +Ti 4 o 7 )-PbO 2 +CeO 2 Composite anode plate, including Al-based metal plate matrix, TiB 2 +Ti 4 o 7 Ceramic interlayer, PbO 2 +CeO 2 Composite active catalytic layer, Al base metal plate is pure Al plate, thickness is 4mm, TiB 2 +Ti 4 o 7 The dusting thickness of the mixed powder is 2mm, and the total thickness of the composite anode plate is 6-8mm. The specific preparation process includes the following steps:

[0033] (1) Pretreatment of Al-based metal plate: Cut an aluminum plate with a thickness of 4mm into a small sample of 60mm×30mm with a wire cutting machine, and use a steel wire to polish the small sample to remove surface oxide film and impurities, and place the small sample in quality Ultrasonic cleaning in 3% NaOH solution for 2 hours, finally washing with distilled water and drying for later use;

[0034] (2)Al@(TiB 2 +Ti 4 o 7 ) Preparation of layered composite board: use a ball mill to grind TiB ...

Embodiment 3

[0038] A kind of core-shell structure Al@(TiB 2 +Ti 4 o 7 )-PbO 2 +CeO 2 Composite anode plate, including Al-based metal plate matrix, TiB 2 +Ti 4 o 7 Ceramic interlayer, PbO 2 +CeO 2Composite active catalytic layer, Al base metal plate is pure Al plate, thickness is 5mm, TiB 2 +Ti 4 o 7 The dusting thickness of the mixed powder is 2mm, and the total thickness of the composite anode plate is 6-8mm. The specific preparation process includes the following steps:

[0039] (1) Pretreatment of Al-based metal plate: Cut an aluminum plate with a thickness of 5 mm into a small sample of 60 mm × 30 mm with a shearing machine, and use a 16 mm benchtop drilling machine to polish the small sample to remove surface oxide film and impurities. Place in a 3% NaOH solution by ultrasonic cleaning for 2 hours, and finally wash with distilled water and dry for later use;

[0040] (2)Al@(TiB 2 +Ti 4 o 7 ) Preparation of layered composite board: use a ball mill to grind TiB 2 and Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com