A method, bacterial strain and application for reducing by-product succinic acid in L-malic acid fermentation process

A fermentation process, malic acid technology, applied in the field of bioengineering, can solve the problems of rapid equipment depreciation, high content, low product conversion rate or production efficiency, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Example 1: frd A gene and frd Construction of B gene knockout vector

[0076] This embodiment includes the following steps:

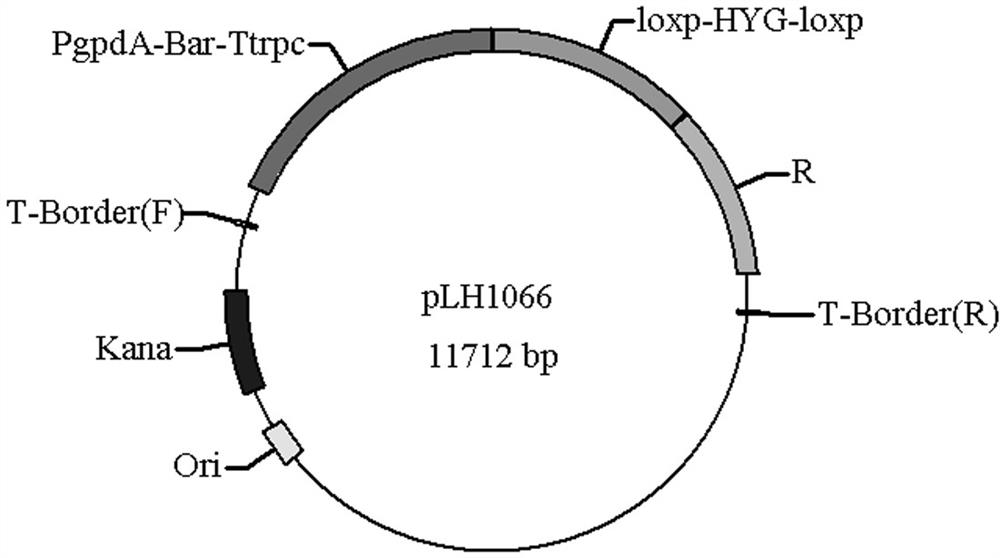

[0077] (1) frd Construction of A gene knockout vector

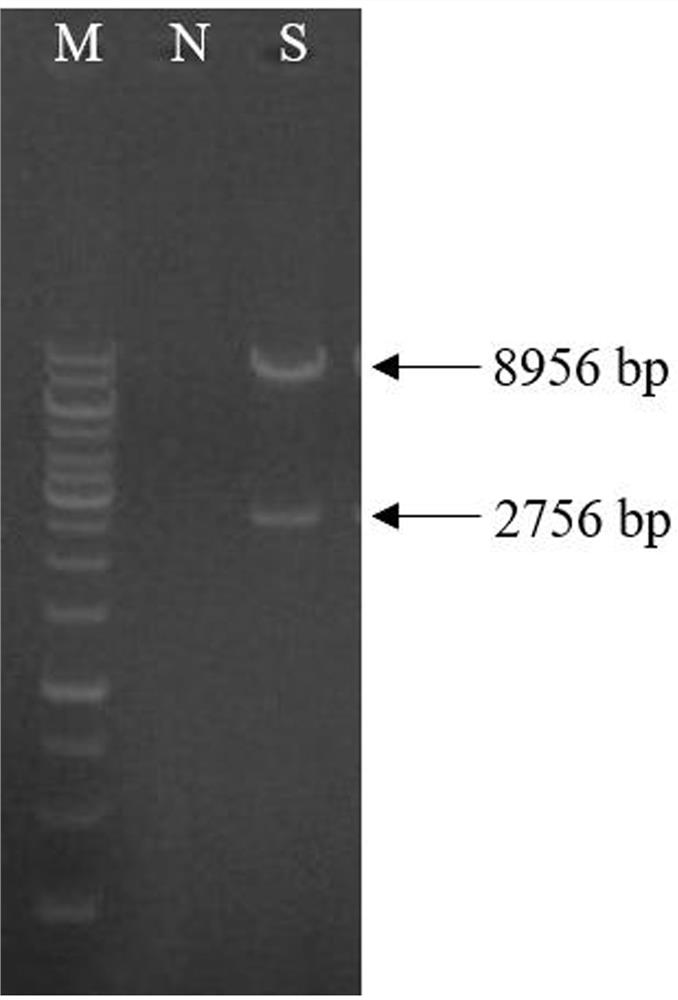

[0078] for amplification frd The downstream sequence fragment of A gene, using the Aspergillus niger ATCC1015 genome as a template to design amplification primers frd A-F-F and frd A-F-R, recovered by PCR amplification frd A gene downstream sequence fragment, via Xba I and Speech After I double enzyme digestion and gel recovery, it was ligated with the vector pLH594 obtained by the same restriction endonuclease treatment with the help of the One-Step Clone Kit kit, and the ligated product was transformed into E. coli In JM109 competent cells, spread evenly in LB solid medium containing 100 µg / mL kanamycin resistance, culture upside down at 37°C overnight, pick a single clone and verify it by colony PCR and plasmid double enzyme digestion ( figure 2 ), get a successful c...

Embodiment 2

[0094] Embodiment 2: Aspergillus niger frd A and frd Obtaining of B gene knockout strain

[0095] This embodiment is realized through the following steps:

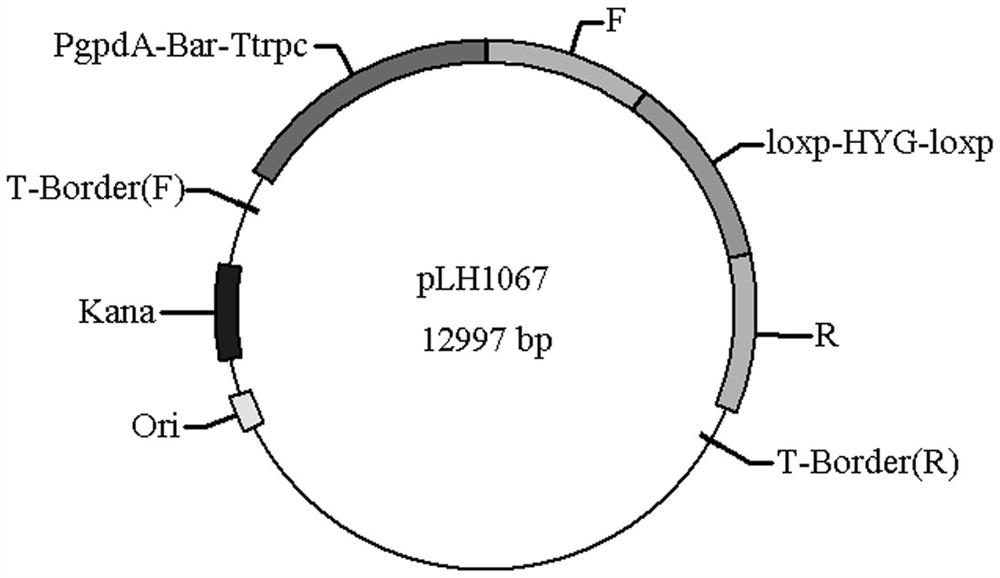

[0096] (1) frd Construction of A Gene Knockout Strain K1

[0097] The vector pLH1067 was transferred to Agrobacterium, and then the Agrobacterium was co-cultured with Aspergillus niger host strain S489 on IM medium for Agrobacterium-mediated transformation. After 2.5 days of culture, the culture product was evenly spread on CM medium for cultivation Until the transformants grow out, the transformants are transferred to different media for screening, and their phenotypes on different media should be resistant to hygromycin and sensitive to glufosinate-ammonium. Genome verification of such transformants is carried out. The primers for verification were designed (Table 1), and the amplification results met the negative amplification of the left and right homology arms ( Figure 12 (P1 / P2), Figure 13 (P3 / P4)), the le...

Embodiment 3

[0108] Example 3: Application of engineering strains to produce L-malic acid by fermentation

[0109] Aspergillus niger constructed by the present invention frd A gene and frd The method for producing malic acid by fermenting B gene knockout engineering strains K1 and K2 in shake flasks, its concrete steps are as follows:

[0110] First, the obtained engineering strains K1 and K2 were inoculated on PDA medium and placed in an incubator at 28°C for upside-down culture for 5 days until sufficient conidia were produced;

[0111] Then, the conidia of strains K1 and K2 were collected and inoculated in malic acid fermentation medium, wherein the final concentration of spores was 1*10 8 cells / mL, the shake flask was placed at 28°C, 200 rpm and cultured for 5 days.

[0112] The composition of the malic acid fermentation medium is: glucose 100g / L, bacto-peptone 6 g / L, anhydrous potassium dihydrogen phosphate 0.15 g / L, anhydrous dipotassium hydrogen phosphate 0.15 g / L, calcium chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com