Coal-fired boiler with low carbon dioxide emission and combustion method

A low carbon dioxide, coal-fired boiler technology, applied in the field of boiler combustion, can solve the problems of large emission of pollutants, high post-processing cost, large processing load, etc. load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

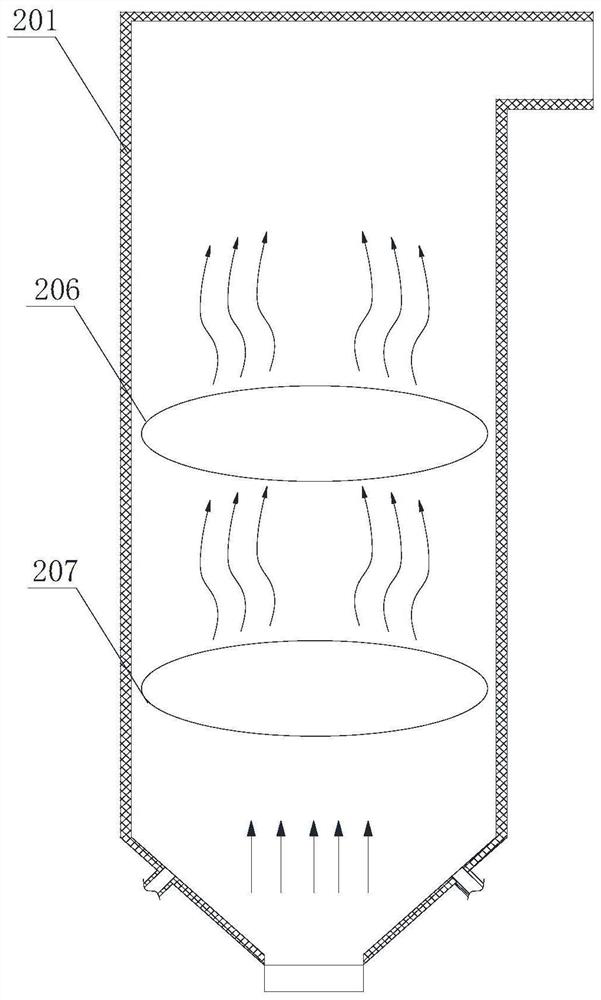

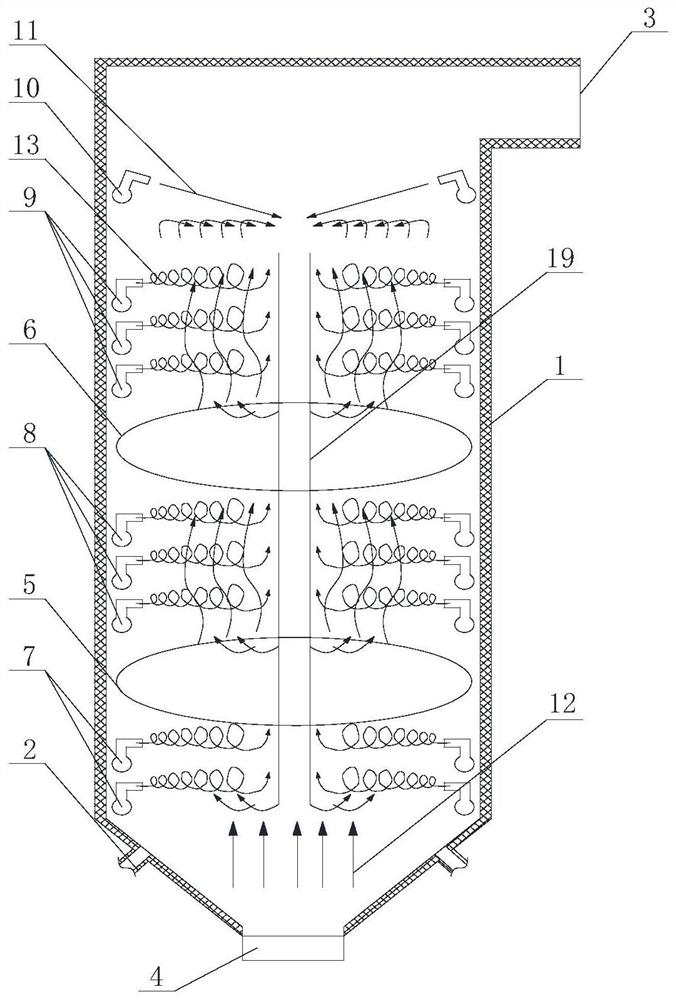

[0057] Such as Figure 3 to Figure 5 The shown coal-fired boiler with low carbon dioxide emissions includes a furnace body 1, and the furnace body 1 is provided with a bottom air inlet 2, an air exhaust port 3, a combustion air supply area 5 and a burnout air supply area 6, so that The diagonal air inlets 14 of the combustion air supply area 5 and the burnout air supply area 6 supply air to the furnace body 1 to form a tangential wind field, and also include a sunken air supply area above the burnout air supply area 6 10. The sunken air supply area 10 is used to inject a downdraft airflow 11 to the center of the furnace body 1, and the downdraft airflow 11 passes through the central windless area 17 of the tangential wind field and sinks to the bottom and the bottom of the boiler Updraft 12 mixing.

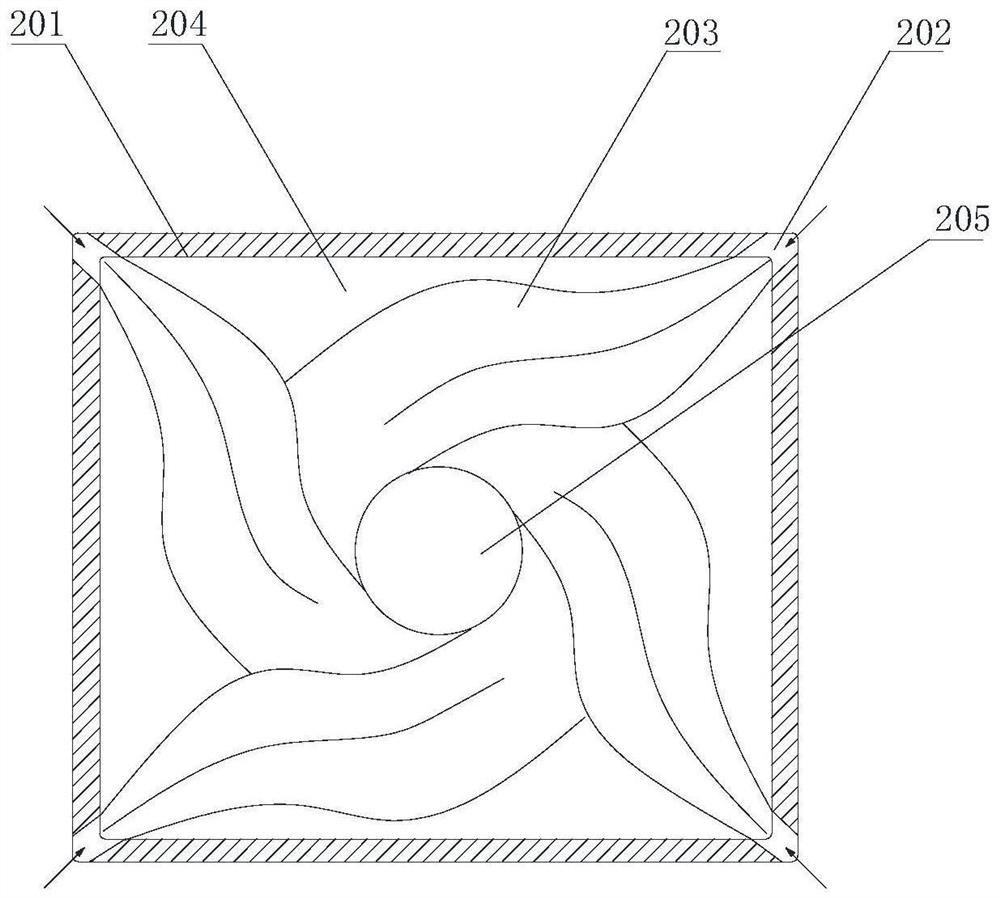

[0058] In some embodiments, such as Figure 4 As shown, the sunken air supply area 10 includes a first air supply pipe 15 installed on the inner wall of the furnace body 1, the ...

Embodiment 2

[0064] On the basis of Example 1, such as image 3 As shown, the furnace body 1 is also provided with a lower air supply area 7 and a middle air supply area 8, the lower air supply area 7 is located below the combustion air supply area 5, and the middle air supply area 8 is located at Between the combustion air supply area 5 and the burnout air supply area 6, the lower air supply area 7 includes two sets of air supply assemblies, and the middle air supply area 8 includes three sets of air supply assemblies, such as Figure 5 As shown, the air supply assembly includes diagonal air inlets 14, which are used to supply air into the furnace body 1 to form a tangential wind field, and two adjacent diagonal air inlets 14 are arranged between There is a second air supply pipe 16, and the second air supply pipe 16 is used to distribute air to the tangential wind field; the air supply volume of the central air supply area 8 is 25% to 35% of the total air volume entering the furnace body...

Embodiment 3

[0072] Such as Figure 7 to Figure 9As shown, on the basis of the above-mentioned embodiments, the nozzle 18 is detachably connected to the air outlet 163 of the first air supply pipe 15 and the second air supply pipe 16, and the nozzle 18 includes a nozzle body 181. The nozzle main body 181 is provided with a helical groove 182 extending helically along the inner wall of the nozzle main body 181. The nozzle main body 181 is provided with a partition 185, and the partition 185 divides the inner space of the nozzle main body 181 into an air inlet connected to the inlet port. area and the cyclone area connected to the gas outlet, the partition 185 is provided with a chamfered hole 186 connecting the inlet area and the cyclone area, the central axis of the chamfered hole 186 has an included angle with the central axis of the partition 185, and the nozzle The main body 181 is also provided with at least one swirl-assisting tube 184, the inside of which swirl-assisting tube 184 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com