Silicon-carbon-carbon nanotube composite negative electrode material and preparation method and application thereof

A carbon nanotube composite and negative electrode material technology, which is applied in the direction of carbon nanotubes, negative electrodes, nanocarbons, etc., can solve the problems of silicon negative electrode electrochemical activity and low volume expansion effect, so as to improve electrochemical activity and stability, realize Effect of high-volume preparation, good electrical conductivity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention proposes a method for preparing a silicon-carbon-carbon nanotube composite negative electrode material, which is characterized in that it comprises the following steps:

[0021] S1: Add nano-silica powder into the mixed solution containing surfactant, stir and sonicate, then add resorcinol and formaldehyde solution in sequence, heat and stir, filter, wash and dry to obtain the precursor powder of phenolic-wrapped silicon; The mixed solution is composed of water, alcohol and ammonia water.

[0022] A surfactant is added to disperse the nano-silicon more uniformly, so that the coating of the phenolic resin is more uniform.

[0023] The mixed solution is composed of water, alcohol and ammonia water. Resorcinol and formaldehyde must react in this environment to form phenolic resin, which is slowly and evenly coated on the surface of nano-silicon.

[0024] Preferably, the mol ratio of described resorcinol and formaldehyde is 1:(1~2), reacts more evenly under t...

Embodiment 1

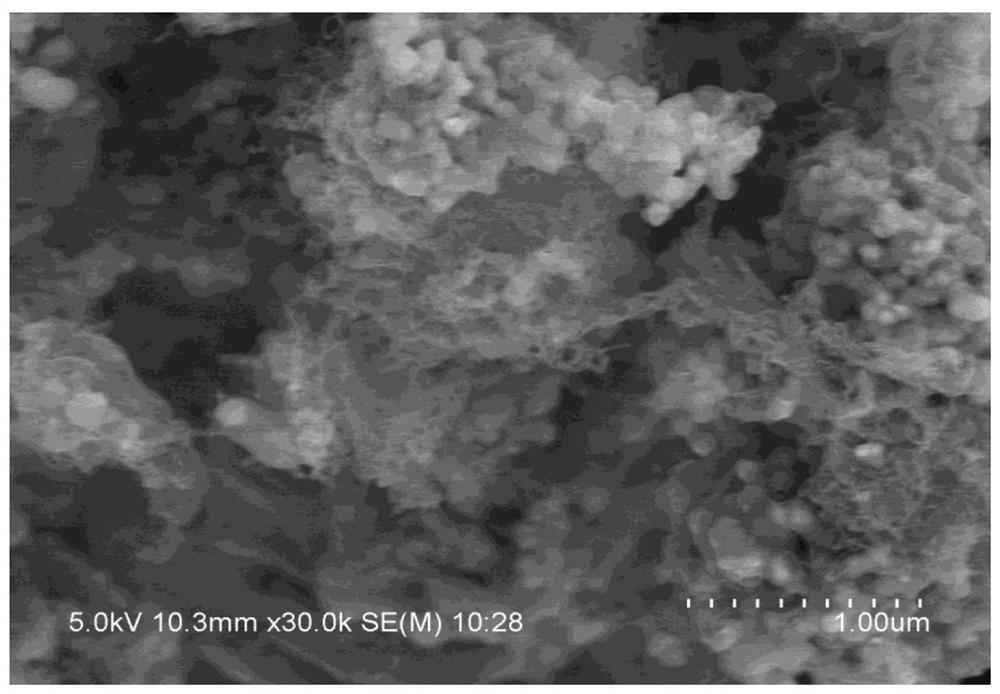

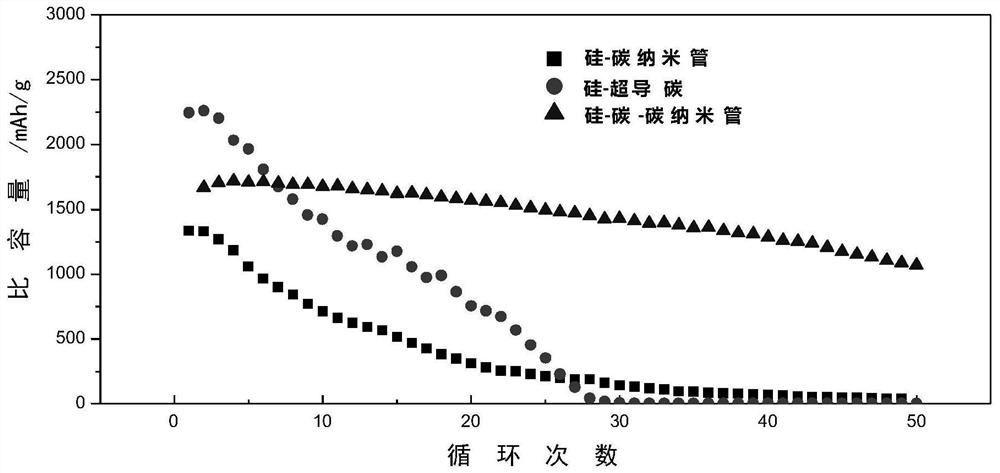

[0040] This embodiment provides a silicon-carbon-carbon nanotube composite negative electrode material, which is composed of carbon-wrapped nano-silicon and carbon nanotubes grown in situ, and has a three-dimensional network structure; the three-dimensional network structure is composed of carbon nanotubes grown in situ Nanotubes are built; carbon-wrapped nano-silicon is dispersed in the three-dimensional network structure. The particle size of the nano-silicon is 30-80nm, the diameter of the in-situ grown carbon nanotube is 10-50nm, and the length is 1-10μm.

[0041]This embodiment also provides a method for preparing the silicon-carbon-carbon nanotube composite negative electrode material described above, comprising the following steps:

[0042] (1) Add 0.50g of nano-silica powder (30-80nm in particle size) to a mixed solution containing 0.1g of dodecyltrimethylammonium bromide in 40ml of water, 360ml of ethanol and 4ml of ammonia and stir, and ultrasonically disperse evenly...

Embodiment 2

[0049] This embodiment provides a silicon-carbon-carbon nanotube composite negative electrode material, which is composed of carbon-wrapped nano-silicon and carbon nanotubes grown in situ, and has a three-dimensional network structure; the three-dimensional network structure is composed of carbon nanotubes grown in situ Nanotubes are built; carbon-wrapped nano-silicon is dispersed in the three-dimensional network structure. The particle size of the nano-silicon is 100-150nm, the diameter of the in-situ grown carbon nanotube is 50-200nm, and the length is 1-10 μm.

[0050] This embodiment also provides a method for preparing the silicon-carbon-carbon nanotube composite negative electrode material described above, comprising the following steps:

[0051] (1) Add 0.50g of nano-silica powder (100-150nm in particle size) to a mixed solution containing 0.02g of dodecyltrimethylammonium bromide in 80ml of water, 320ml of ethanol and 4ml of ammonia and stir, and ultrasonically dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com