Self-crosslinking graphene dispersing agent, preparation method and nano carbon material dispersion liquid

A graphene dispersant and nano-carbon material technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as low dispersion concentration, unsatisfactory production and life, and large amount of dispersant, so as to avoid experimental steps , the effect of excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

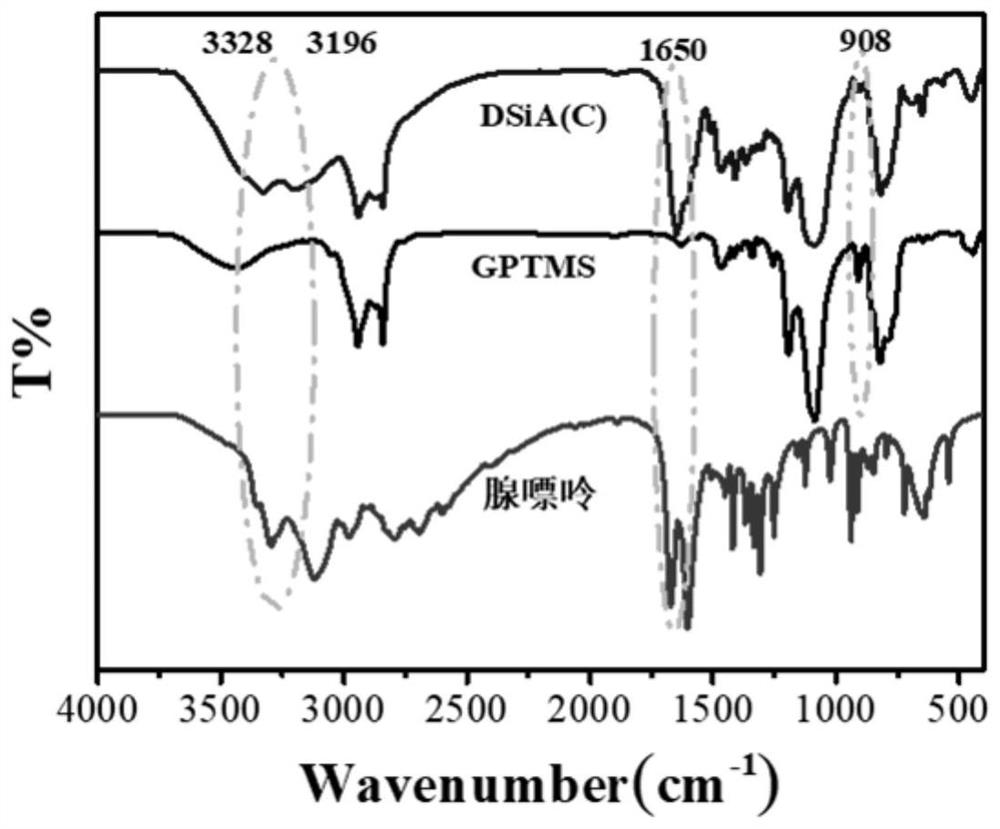

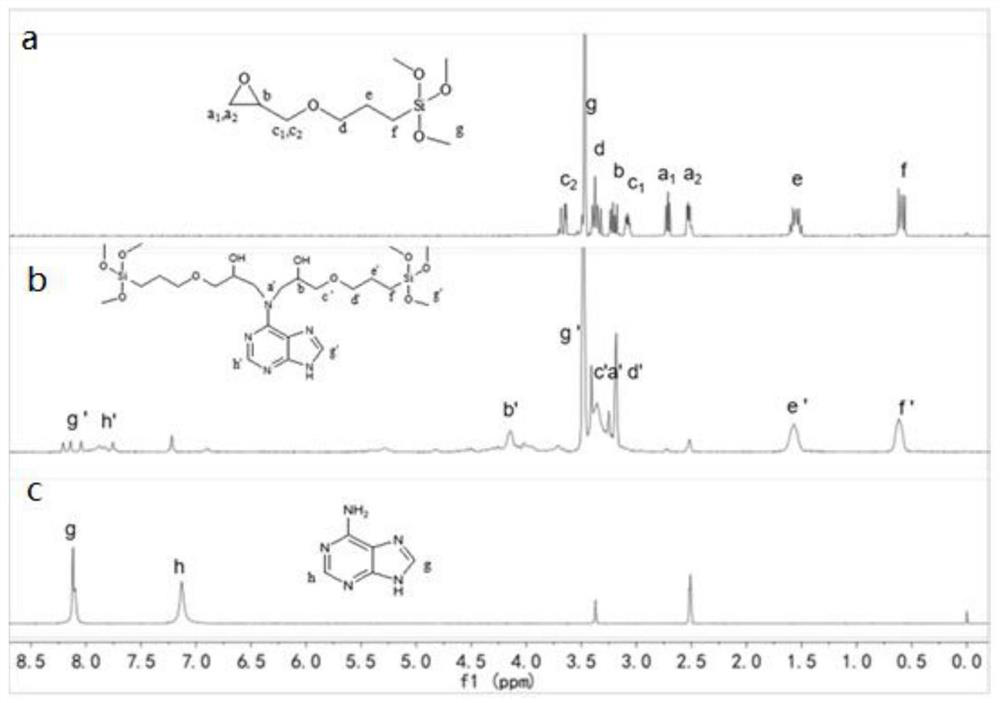

[0043] The invention discloses a graphene dispersant, its structure is:

[0044]

[0045] The preparation method of above-mentioned graphene dispersant, concrete steps are as follows:

[0046] 1) Add 1g of adenine and 3.5g of 3-glycidyloxypropyltrimethoxysilane to 50ml of anhydrous methanol reagent, put them in a flask, stir and react at 65°C for 36h, and take out the product after the reaction , cooled to room temperature, and then the cooled solution was transferred to a rotary evaporator, and methanol was removed by rotary evaporation at 40° C. in a vacuum state, thereby obtaining a dispersant precursor.

[0047] 2) Take 2g of the dispersant precursor, add it to 40ml of 0.1mol / L formic acid aqueous solution, ultrasonicate the mixed solution for 5 minutes in a water bath to make it evenly mixed, then transfer it to a flask, stir and react at 25°C for 72h, Thus a DSiA solution is obtained. The DSiA solution obtained by the reaction was configured to 10 mg / mL with deionized...

Embodiment 2

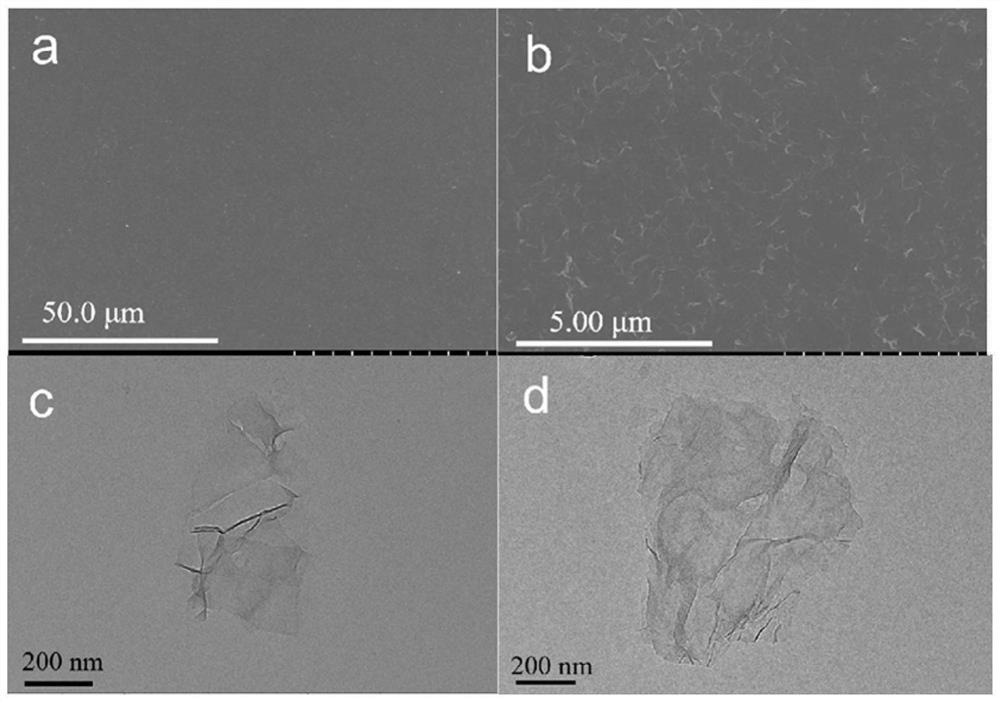

[0051] A kind of preparation method of graphene dispersion liquid has used dispersant described in embodiment 1, and concrete preparation method is as follows:

[0052] Take 5mg of graphene powder, add 1mL, 0.5mL, 0.25mL, 0.17mL, 0.13mL of 10mg / mL DSiA solution respectively, use deionized water to prepare a 0.5mg / mL graphene dispersion, and ultrasonicate it in a water bath Preliminary dispersion was carried out for 5 minutes, and further ultrasonic dispersion was carried out for 30 minutes with an ultrasonic cell pulverizer to obtain the corresponding graphene dispersion. The ultrasound power was 350W during ultrasound, and the ultrasound was stopped for 3 seconds every 3 seconds for 30 minutes.

[0053] A series of 0.5mg / mL GR dispersions were configured with a mass ratio of DSiA:GR of 2:1, 1:1, 1:2, 1:3 and 1:4, and were dispersed by an ultrasonic cell pulverizer to obtain the table A very homogeneous dispersion. Under the condition that the ratio of DSiA:GR is 1:1, the GR...

Embodiment 3

[0055] A kind of preparation method of carbon nanotube dispersion liquid, has used dispersant described in embodiment 1, and concrete preparation method is as follows:

[0056] Take 5mg of multi-walled carbon nanotube powder and add them to 0, 0.5mL, 0.25mL, 0.17mL, 0.13mL, 0.1mL of DSiA solution, and then add deionized water to 10mL to configure a 0.5mg / mL dispersion solution, the prepared dispersion liquid was ultrasonicated in a water bath for 5 minutes, and then ultrasonically dispersed for 30 minutes using an ultrasonic cell pulverizer to obtain the corresponding multi-walled carbon nanotube dispersion. The ultrasonic power is 350W, and the ultrasound is stopped for 3 seconds every 3 seconds, and the time is 30 minutes.

[0057] The DSiA:CNT ratios were 0:1, 1:1, 1:2, 1:3, 1:4, and 1:5 respectively, and the CNT dispersion liquid with a CNT concentration of 0.5mol / L was prepared. When the DSiA:CNT ratio of the newly prepared dispersion is 1:5, the dispersion is still unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com