Sound insulation polyvinyl acetal resin and preparation method and application thereof

A technology of polyvinyl acetal resin and polyvinyl alcohol, which is applied in the field of sound-insulating polyvinyl acetal resin and its preparation and application, and can solve the problem of reducing sound insulation performance and safety performance, reducing the mechanical properties, safety and processing performance of PVB resin Influence and other problems, to achieve the effect of simple process, easy operation, and improved plasticizer absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0038]A preparation method of sound-insulating polyvinyl acetal resin (or new polyvinyl acetal resin), the steps are: adding 1000 kg of polyvinyl alcohol and 10000 kg of deionized water into a dissolution kettle at normal temperature, raising the temperature to 95°C, Stir to make it completely dissolve into an aqueous solution of polyvinyl alcohol, then filter, then cool down to 40°C, add a certain amount (see Table 1 for specific dosage) of long-chain aliphatic aldehyde, 6kg of antioxidant 1010, and stir at high speed for 30 minutes to prepare uniform polyethylene Alcohol / long-chain fatty aldehyde mixed solution; the above-mentioned polyvinyl alcohol / long-chain fatty aldehyde mixed solution and hydrochloric acid aqueous solution with a mass concentration of 1.0% are passed through each of them within 8 minutes at the ratio of 100:20 by volume at 30°C. The pipeline continuously enters the tubular reactor with heating and cooling functions, reacts for 20 minutes, and then transf...

Embodiment 8-14

[0046] Put the ordinary PVB resin powder in the amount of 1100KG / H at the screw speed of 700RPM-900RPM, and add it through the automatic feeding system with weight loss scale In the twin-screw extruder, at the same time, plasticizers containing UV agents (ie: ultraviolet absorbers), antioxidants and pigments are passed through at a rate of 400KG / H The liquid material injection port on the barrel of the type twin-screw extruder is injected into the extruder, and the liquid material containing the cohesive force regulator is injected into the extruder synchronously through another liquid material injection port, etc., and the processing temperature is set Between 90 and 170°C, various materials are melted and plasticized through twin-screw shearing; in addition, 200KG of new polyvinyl acetal resin powder is 210KG / H at 300RPM-400RPM screw speed, through a weight loss scale. The automatic feeding system is added In the type twin-screw extruder, the plasticizer is passed throug...

Embodiment 15

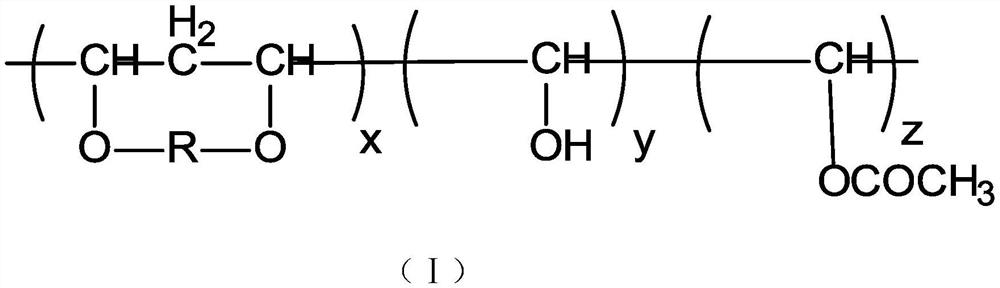

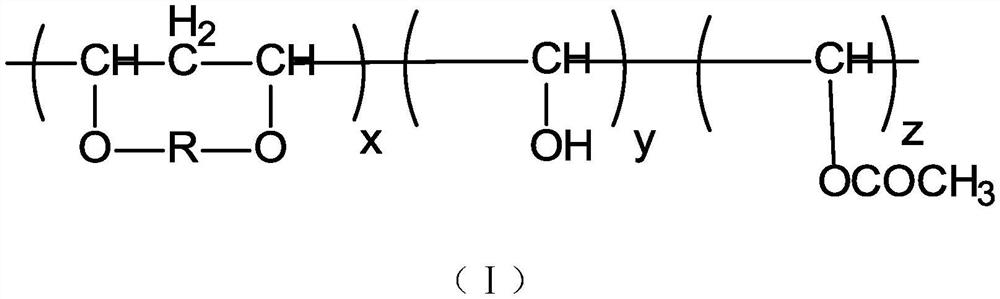

[0053] A sound-insulating polyvinyl acetal resin, the compound has the chemical structural formula shown in (I):

[0054]

[0055] In formula (I): x=550-620, y=440-500, z=3-24;

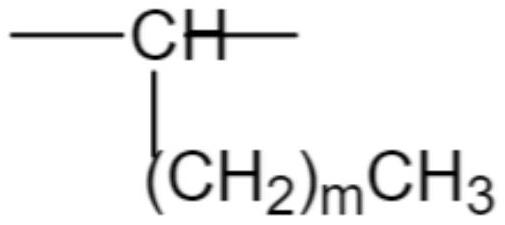

[0056] The chemical structural formula of R is:

[0057]

[0058] In the formula: m=6, 7, 8, 9, 10, 11 or 12.

[0059] The physical and chemical data of the sound-insulating polyvinyl acetal (resin) are: a viscosity of 1500-2000 mPa·s, a hydroxyl content of 18%-21%, a glass transition temperature of 65°C-75°C, and is in the state of white powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com