Portland cement

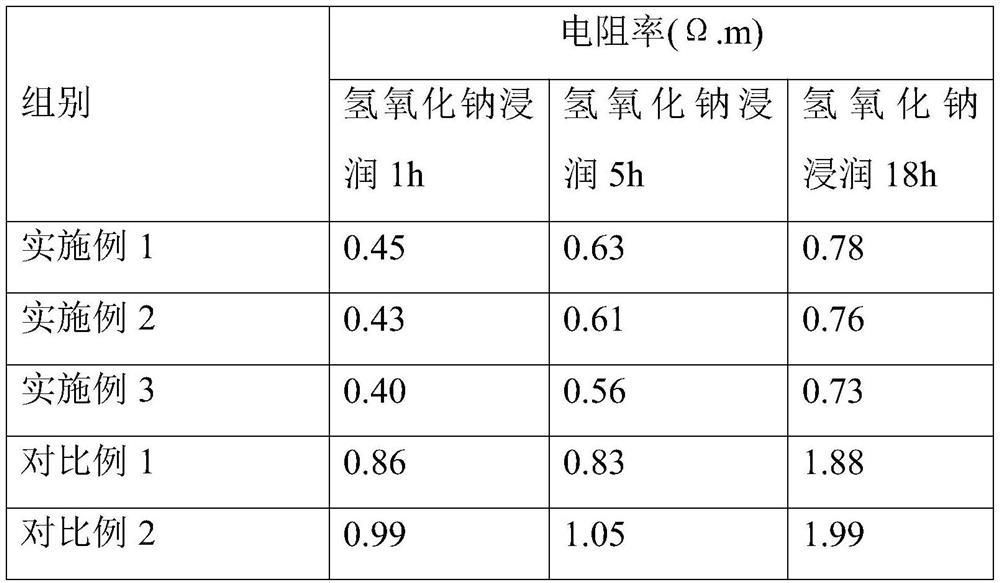

A Portland cement and acrylic emulsion technology, which is applied in cement production, sustainable waste treatment, solid waste management, etc., can solve the problems of reducing cement use efficiency and poor anti-corrosion performance, and achieve improved electrical conductivity and increased shrinkage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of Portland cement of the present embodiment comprises the following raw materials in parts by weight:

[0033] 50 parts of Portland cement, 15 parts of polyurethane composite cyclodextrin modified grafted bentonite, 10 parts of synergistic additives, 5 parts of dispersed polyaniline, 1 part of surfactant sodium lauryl sulfate;

[0034] The preparation method of the polyurethane composite cyclodextrin modified grafted bentonite of the present embodiment is:

[0035] Step 1, modification of bentonite: send bentonite to calcination at 200°C for 10 minutes, after calcination, cool to room temperature naturally, send it into acrylic emulsion at a weight ratio of 1:3, and then add 10% of the total amount of bentonite to silane The joint agent KH560, the reaction speed is 100r / min, the reaction temperature is 75°C, and the reaction time is 20min; then add the initiator azobisisobutyronitrile with 2% of the total amount of bentonite, and continue to stir for 20min. Afte...

Embodiment 2

[0048]A kind of Portland cement of the present embodiment comprises the following raw materials in parts by weight:

[0049] 60 parts of Portland cement, 25 parts of polyurethane composite cyclodextrin modified grafted bentonite, 20 parts of synergistic additives, 15 parts of dispersed polyaniline, 6 parts of surfactant sodium lauryl sulfate;

[0050] The preparation method of the polyurethane composite cyclodextrin modified grafted bentonite of the present embodiment is:

[0051] Step 1, modification of bentonite: send bentonite to 300°C for calcination for 20 minutes, after calcination, cool to room temperature naturally, send it into acrylic emulsion according to the weight ratio of 1:3, and then add 20% of the total amount of bentonite to silane coupling Joint agent KH560, the reaction speed is 500r / min, the reaction temperature is 85°C, and the reaction time is 30 minutes; then add the initiator azobisisobutyronitrile with 5% of the total amount of bentonite, continue to ...

Embodiment 3

[0063] A kind of Portland cement of the present embodiment comprises the following raw materials in parts by weight:

[0064] 50-60 parts of Portland cement, 15-25 parts of polyurethane composite cyclodextrin modified grafted bentonite, 10-20 parts of synergistic additives, 5-15 parts of dispersed polyaniline, surfactant lauryl sulfate Sodium 1-6 parts;

[0065] Preferably, the Portland cement includes the following raw materials in parts by weight:

[0066] 55 parts of Portland cement, 20 parts of polyurethane composite cyclodextrin modified grafted bentonite, 15 parts of synergistic additives, 10 parts of dispersed polyaniline, and 3 parts of surfactant sodium lauryl sulfate.

[0067] The preparation method of the polyurethane composite cyclodextrin modified grafted bentonite of the present embodiment is:

[0068] Step 1, modification of bentonite: send bentonite to calcination at 200-300°C for 10-20min, after calcination, cool to room temperature naturally, send it into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com