Oxidation desulfurization method and device for coal in overheated near-critical water

A technology of near-critical superheating and water oxidation, applied in solid fuel, petroleum industry, fuel, etc., to achieve the effects of reducing economic losses, reducing material requirements, and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

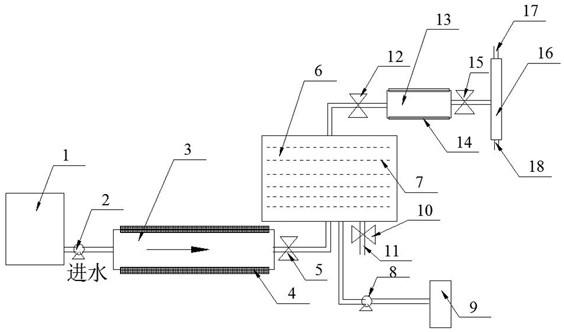

Image

Examples

Embodiment 1

[0029] The coal sample is Taiyuan steam coal, with a combustible sulfur content of 1% on a dry, ash-free basis.

[0030] Take 1000g of coal sample, uniformly pulverize the average particle size of about 0.5~1mm, and put it into the reactor 6. The preheater 3 generates high-temperature superheated steam, and the high-temperature superheated steam passes into the reactor to heat the pulverized coal to 420°C. Then the water in the preheater is heated to 480°C through the external heating jacket 4, and the pressure is increased to 10MPa. The superheated and near-critical fluid enters the reactor through the back pressure valve 5, and then the reactor is fed with oxygen to control the overheating. The oxygen coefficient is 1.3. React for 5 minutes, the gas discharged from the gas-liquid separator gas phase outlet in the reaction process is passed in the solvent bottle 1 that sodium hydroxide solution is housed, and the liquid collection flowing into the clean solvent bottle 2 from...

Embodiment 2

[0032] The coal sample is Datong raw coal with a combustible sulfur content of 1.1% on a dry ash-free basis.

[0033] The operation process and method are the same as the implementation example 1. The main parameters differ as follows. Coal sample 800g, uniformly crushed with an average particle size of about 1~2mm. First pass high-temperature superheated steam to heat the pulverized coal to 420°C. The water in the preheater is heated to 480°C, the pressure is maintained at 15MPa, oxygen is introduced into the reactor, the oxygen peroxide coefficient is 1.2, and the reaction is carried out for 4 minutes.

[0034] Sulfate and sulfite ions were not detected in the solution of solvent bottle 1 where the gas phase was collected. Sulfate and sulfite ions were detected in the solvent bottle 2 where the liquid phase solution was collected, and the mass of sulfur in the liquid phase solution was calculated to be about 8g based on the measured values. Analyzing and measuring the pu...

Embodiment 3

[0036] The coal sample is Changzhi anthracite, with a combustible sulfur content of 0.8% on a dry, ash-free basis.

[0037] The operation process and method are the same as the implementation example 1. The main parameters differ as follows. The coal sample is 1300g, and the average particle size of uniform grinding is about 1~2mm. The pulverized coal is heated to 420°C by introducing high-temperature steam. The water in the preheater is heated to 520°C, the pressure is maintained at 20MPa, oxygen is introduced into the reactor, the oxygen peroxide coefficient is 1.5, and the reaction is carried out for 8 minutes.

[0038] Sulfate and sulfite ions were not detected in the solution of solvent bottle 1 where the gas phase was collected. Sulfate and sulfite ions were detected in the solvent bottle 2 where the liquid phase solution was collected, and the mass of sulfur in the liquid phase solution was calculated to be about 9.8 g based on the measured values. Analyze and measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com