Method for preferentially extracting lithium and recycling valuable metals from waste ternary lithium ion battery positive electrode materials

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of resource recycling of waste batteries, can solve problems such as high cost of recycling lithium elements, low-quality lithium products, and complicated processes, and achieves low prices, strong hydrophobicity, and high-efficiency treatment processes. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

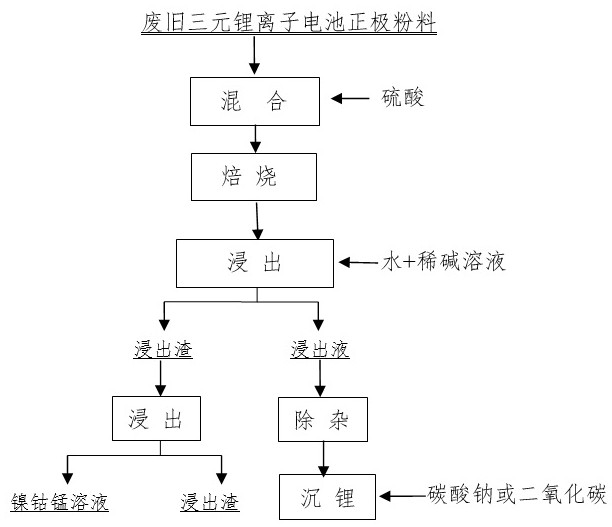

Method used

Image

Examples

Embodiment 1

[0036] Weigh 50g of waste nickel-cobalt-manganese ternary lithium-ion battery positive electrode material, add 24mL of 60% concentrated sulfuric acid, mix well, the material is loose granular after mixing, put the material into the material boat and calcinate with a calciner, the calcining temperature is 400°C, Calcined for 3h, then cooled naturally. After the calcined material is taken out, 150mL of pure water is added for leaching at room temperature. During the leaching process, 5% sodium hydroxide solution is added to adjust the pH value of the leaching solution to 10.4. The leaching time is 1h. After leaching is completed, filter, and the filtrate and filter residue are sampled for detection. The filtrate is subjected to precipitation and ion exchange. After removing impurities, sodium carbonate is added to produce lithium carbonate product. After slurrying the filter residue at a solid-to-liquid ratio of 1:5, heat it to 60°C, add sulfuric acid solution to adjust the pH t...

Embodiment 2

[0038] Weigh 500g of waste nickel-cobalt-manganese ternary lithium-ion battery positive electrode material, add 145mL98% concentrated sulfuric acid, mix well, the material is loose granular after mixing, put the material into the material boat and use a calciner for calcination, the calcination temperature is 600°C, Calcined for 1h, then cooled naturally. After the calcined material is taken out, 2500mL of pure water is added for leaching at room temperature. During the leaching process, 10% sodium hydroxide solution is added to adjust the pH value of the leaching solution to 10, and the leaching time is 100 minutes. After removing impurities, sodium carbonate is added to produce lithium carbonate product. After the filter residue is slurried at a solid-to-liquid ratio of 1:3, heat to 60°C, add sulfuric acid solution to adjust the pH to 0.9, react for 15 minutes, add sulfuric acid and hydrogen peroxide in parallel, control the pH to about 1.0 during the process, react for 60 m...

Embodiment 3

[0040] Weigh 1000g of waste nickel-cobalt-manganese ternary lithium-ion battery positive electrode material, add 920mL of 30% concentrated sulfuric acid, mix well, after mixing well, the material is loose granular, put the material into the material boat and use a calciner for calcination, the calcination temperature is 500°C, Calcined for 4h, then cooled naturally. After the calcined material is taken out, 4000mL of pure water is added for leaching at room temperature. During the leaching process, 20% lithium hydroxide solution is added to adjust the pH value of the leaching solution to 10.5. The leaching time is 2 hours. After the leaching is completed, filter, and the filtrate and filter residue are sampled and tested. The filtrate is subjected to precipitation and ion exchange. After removing impurities, sodium carbonate is added to produce lithium carbonate product. After the filter residue is slurried at a solid-to-liquid ratio of 1:4, heat to 60°C, add sulfuric acid sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com