Lithium titanate/lithium ion conductor/carbon composite material and preparation method and application thereof

A carbon composite material and composite material technology, which is applied in secondary battery repair/maintenance, active material electrodes, electrical components, etc., can solve problems such as flatulence conductivity, achieve good high and low temperature characteristics, mild conditions, and suppress gas production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

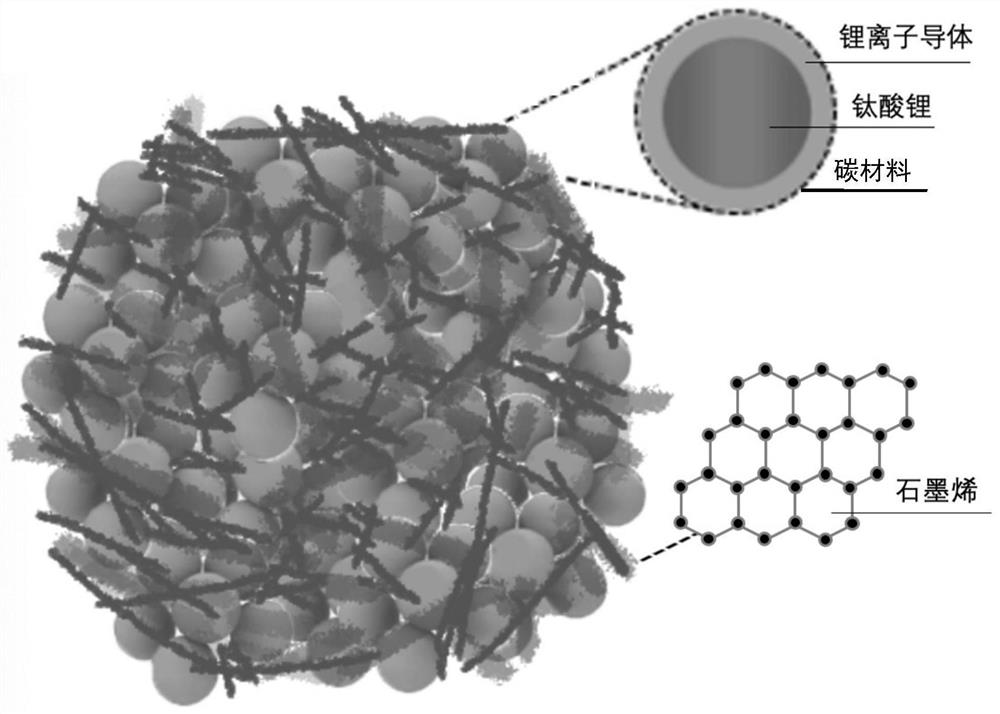

[0036] The second aspect of the embodiment of the present application provides a preparation method of lithium titanate / lithium ion conductor / carbon composite material, comprising the following steps:

[0037] Dissolving the lithium source and other source compounds in a solvent, adding a complexing agent for thermal mixing reaction, to obtain a lithium ion conductor precursor;

[0038] Lithium titanate is mixed with the lithium ion conductor precursor solution, then a precipitant is added for precipitation, and the co-precipitated substance is separated;

[0039] Calcining the co-precipitated material under an inert atmosphere to obtain a lithium titanate / lithium ion conductor composite material, wherein the lithium ion conductor is coated on the outer surface of the lithium titanate;

[0040] After mixing the lithium titanate / lithium ion conductor composite material and the solution of the carbon material, drying treatment and low temperature heat treatment are carried out i...

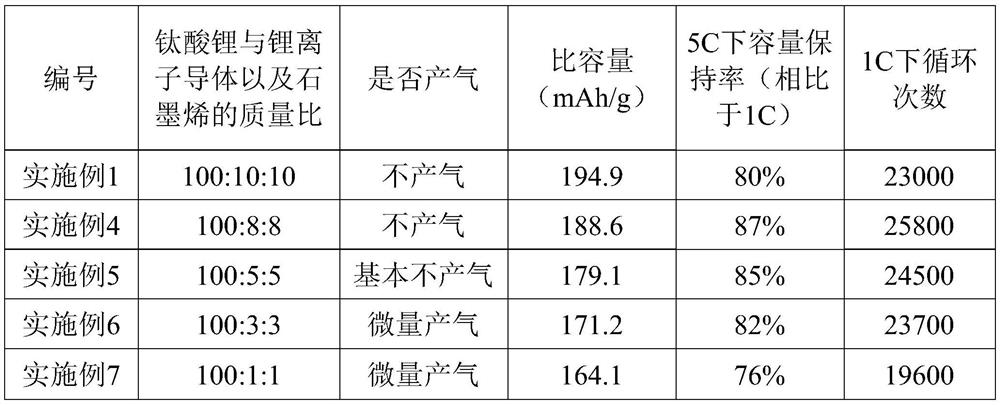

Embodiment 1

[0076] A kind of lithium titanate / lithium ion conductor / graphene composite material, its preparation comprises steps:

[0077] ① Preparation of lithium ion conductor NASICON type lithium germanium aluminum phosphate (Li 1.6 Al 0.6 Ge 0.8 (PO 4 ) 3 ) precursor solution:

[0078] Dissolve lithium nitrate, aluminum nitrate, germanium methoxide, and ammonium dihydrogen phosphate in an appropriate amount of deionized water at a molar ratio of 1.6:0.6:0.8:3, wherein the molar concentration of lithium nitrate is 0.1mol / L. Add an aqueous citric acid solution that is 4 times the molar ratio of lithium ions and germanium ions in the solution, adjust the pH of the solution to 5, and continue stirring at 80°C for 6 hours to obtain the lithium ion conductor Li 1.6 Al 0.6 Ge 0.8 (PO 4 ) 3 precursor solution.

[0079] ② Preparation of lithium germanium aluminum phosphate / lithium titanate composite material:

[0080] Add lithium titanate with a size of 200nm to the prepared lithium...

Embodiment 2~3

[0093] Embodiment 2-3 Compared with embodiment 1, except that the lithium ion conductor type used when preparing lithium titanate / germanium aluminum phosphate / graphene composite material is different (specifically as shown in the following table 1), other materials, steps all the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com