Bone supported catalyst for producing succinic acid and preparation method thereof

A technology of supporting catalyst and succinic acid, applied in catalyst activation/preparation, catalyst carrier, carboxylic acid anhydride preparation, etc., can solve the problem of loss of supported metal elements, improve tolerance, solve acid-intolerant, and good yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A preparation method of a bone-loaded catalyst producing succinic acid, the method comprising the steps of:

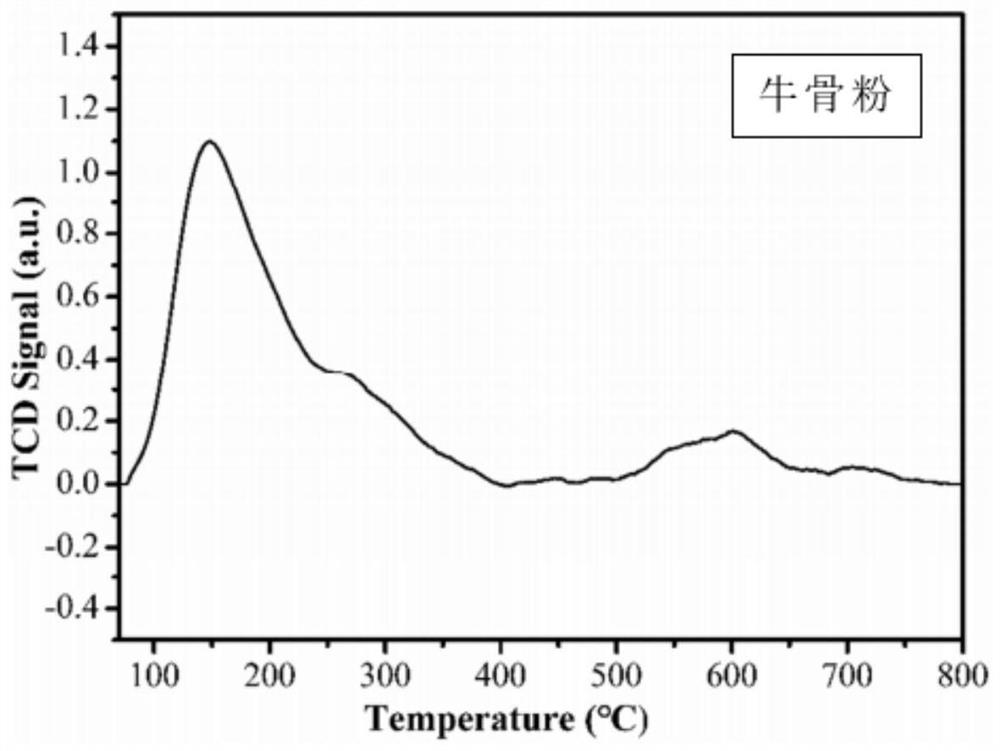

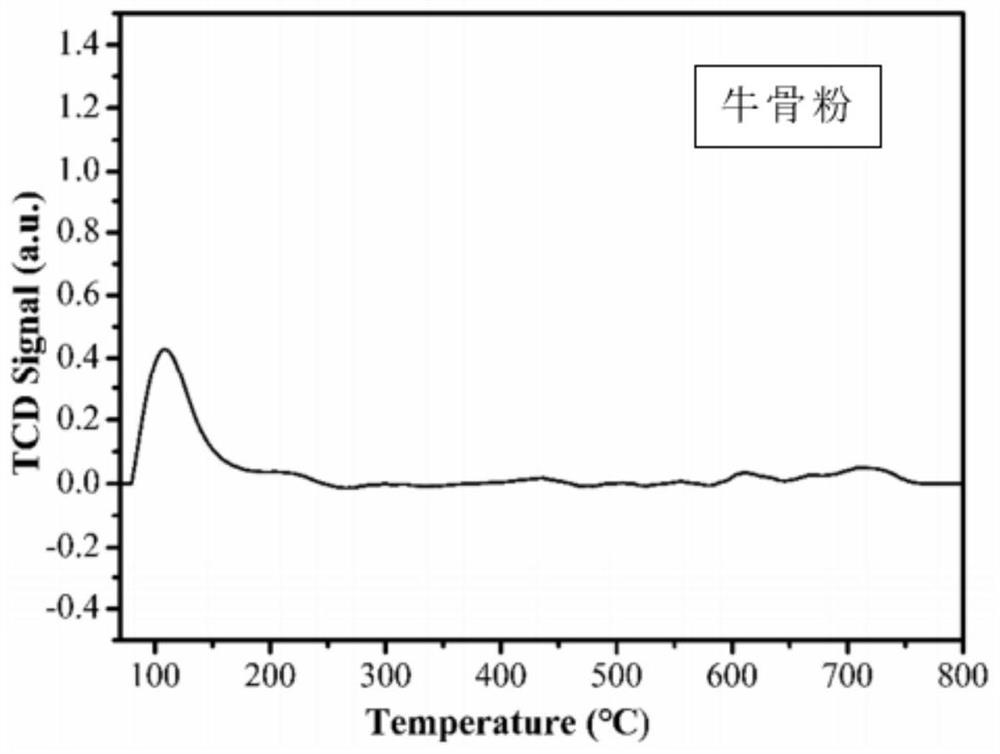

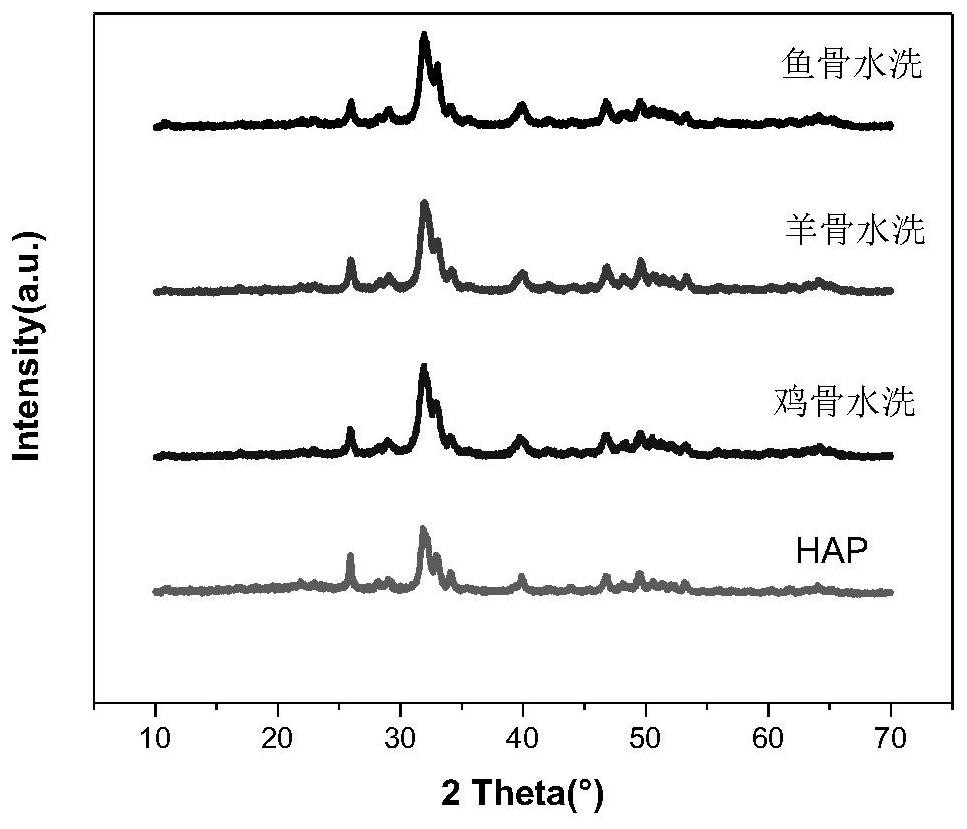

[0045] Step 1, pretreatment, the fresh bovine bone is dried and ground into powder after being washed with water;

[0046] Step 2, impregnation and adsorption, using 50-100 mL of Pd(OAC)2 acetone solution with a concentration of 0.0222-1.11 mg / mL to impregnate 0.50-1.00 g of pretreated bone powder.

[0047] Step 3, drying and activating, filtering and washing with a solvent, drying at 20-100°C for 6-12h, reducing and activating at 150-400°C in a hydrogen atmosphere for 1-6h to obtain Pd with a catalyst metal loading of 0.1%-5%. Loaded bovine bone catalyst (referred to as Pd / bovine bone).

[0048] Catalyst metal loading 1% Pd / bovine bone preparation method embodiment

[0049] Weigh 1g of animal bone powder and add it to a round bottom flask, and add 100ml of acetone. 22.2 mg of palladium acetate was weighed and dissolved in 15 ml of acetone, and then the aceto...

Embodiment 12-16

[0068] Add 50 mg of the metal catalyst as shown in Table 2 according to the operation of Examples 1-12, and adjust the substrate concentration according to the records in Table 12 (add 0.3 g; 1.2 g; 2.4 g and 3 g of maleic anhydride, water 10 mL, respectively Corresponding substrate concentration is 3wt%; 12wt%; 24wt% and 30wt%), in table 2 corresponding catalytic reaction temperature and catalytic reaction time 0.5MPa H 2 Under the conditions, the maleic anhydride hydrogenation reaction test was carried out in the reactor, and the test analysis was carried out according to the test analysis conditions of Examples 1-12, and the results were recorded in Table 2.

[0069] Table 2, the conditions and results for the preparation of succinic acid by embodiment 13-16

[0070]

[0071] The results in Table 2 show that even if the substrate concentration is 30%, the yield of succinic acid can reach 100% by changing the reaction conditions, indicating that the catalyst has high acid...

Embodiment 17-29

[0073] Add the metal catalyst as shown in table 3 according to the operation of embodiment 1-12, and carry out maleic anhydride hydrogenation reaction test under the corresponding catalytic reaction temperature and catalytic reaction time conditions in table 3, according to embodiment 1-12 Test analysis conditions Carry out test analysis, and record the results in Table 3.

[0074] Table 3, conditions and results for the preparation of succinic acid by embodiment 17-24

[0075]

[0076] The research results in Table 3 show that high temperature is beneficial to the catalyst’s activation of hydrogen and the adsorption of substrates. As the temperature further increases, the catalyst still maintains a high selectivity for succinic acid. In addition, with the increase of metal loading, the rate of catalytic reaction is accelerated. It shows that there are more reactive sites on the catalyst with high metal loading. Elevating the hydrogen pressure increases the mass transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com