Temperature-resistant reinforcing agent and fracturing fluid

A technology of reinforcing agent and fracturing fluid, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor temperature resistance and achieve the effects of low residue content, complete gel breaking and low damage in the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The preparation of embodiment 1 temperature-resistant enhancer

[0060] Ethylene glycol, sodium thiosulfate, succinic anhydride, and distilled water are mixed in the water at a mass ratio of 1:6:2:10 and heated for compounding to obtain a temperature-resistant enhancer with a density of 1.137 g / cm 3 ; The compounding temperature is 35° C., and the time is 1 hour.

Embodiment 2

[0061] The preparation of embodiment 2 temperature-resistant enhancer

[0062] Methanol, sodium thiosulfate, maleic anhydride, and distilled water are mixed in the water at a mass ratio of 1:7:3:10 and heated for compounding to obtain a temperature-resistant enhancer with a density of 1.137g / cm 3 ; The compounding temperature is 40° C., and the time is 0.5 hours.

Embodiment 3

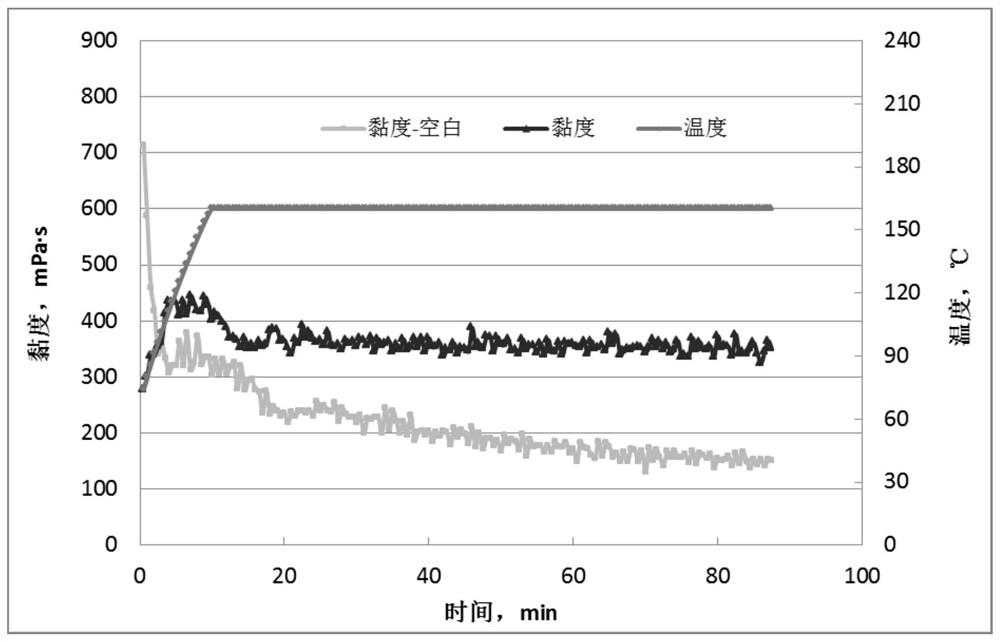

[0063] Example 3 160°C temperature resistance test

[0064] Preparation of base liquid: under stirring conditions, add 5g of polymer thickener to 1000mL of water, add 5.5g of clay stabilizer, then add 7g of drainage aid and 5g of demulsifier in turn, stir continuously for 10min, and put it in a water bath at 30°C , placed at constant temperature for 4h to fully swell, and the viscosity was 49mPa·s.

[0065] Blank group: take 60mL of base fluid, add 0.35g of cross-linking agent into the base fluid drop by drop evenly, mix well to form fracturing fluid, and test its rheological properties by RS6000 rheometer (160°C, 170S -1 , 90min), the result is as follows figure 1 (light gray curve).

[0066] Test group: Take 60mL of base fluid, add 0.48g of temperature-resistant enhancer (prepared in Example 1), stir evenly, add 0.35g of cross-linking agent into the base fluid drop by drop, mix evenly to form high-temperature fracturing fluid, and pass through RS6000 flow The rheology was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com