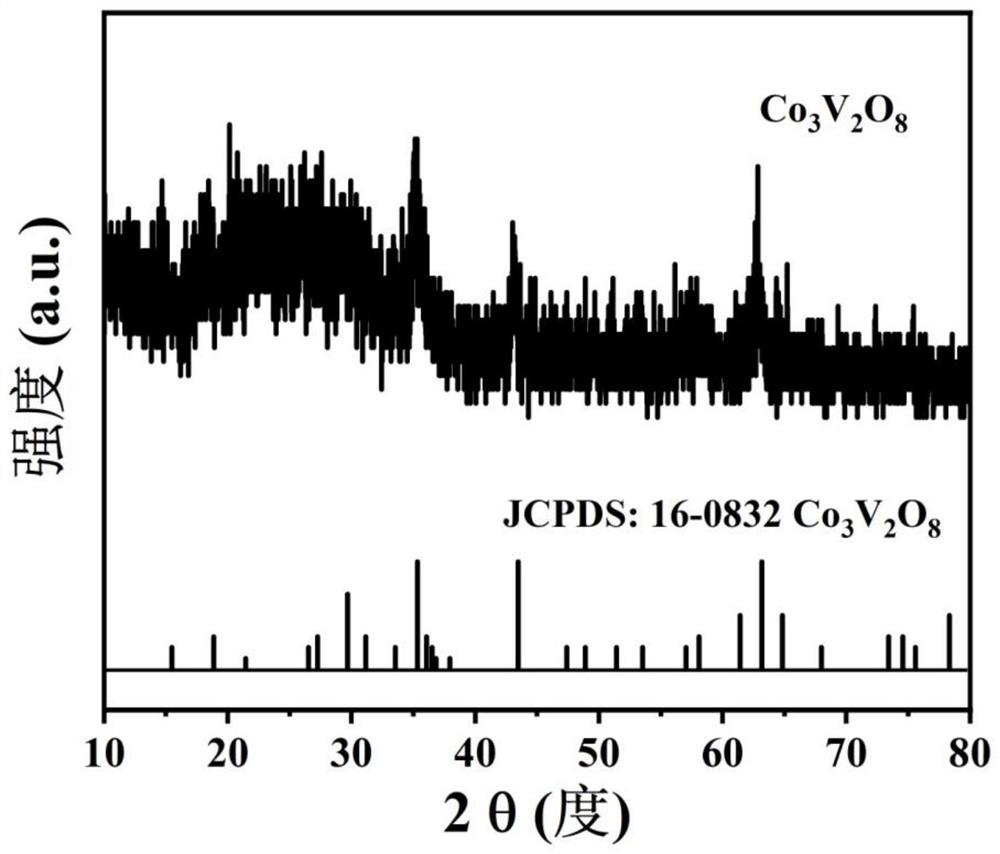

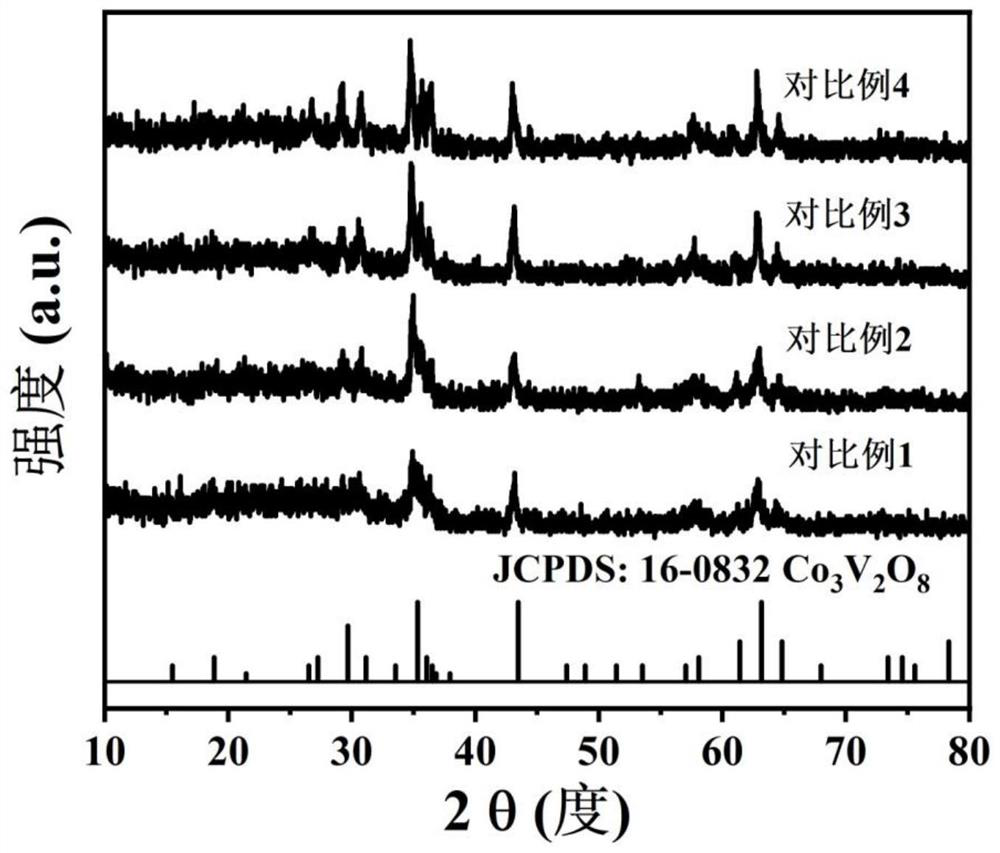

Co3V2O8 bifunctional electro-catalytic material as well as preparation method and application thereof

An electrocatalytic material and dual-function technology, applied in the field of electrocatalytic materials, can solve the problem of no one-dimensional shape, etc., and achieve the effect of low raw material cost, excellent performance, and large limit current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

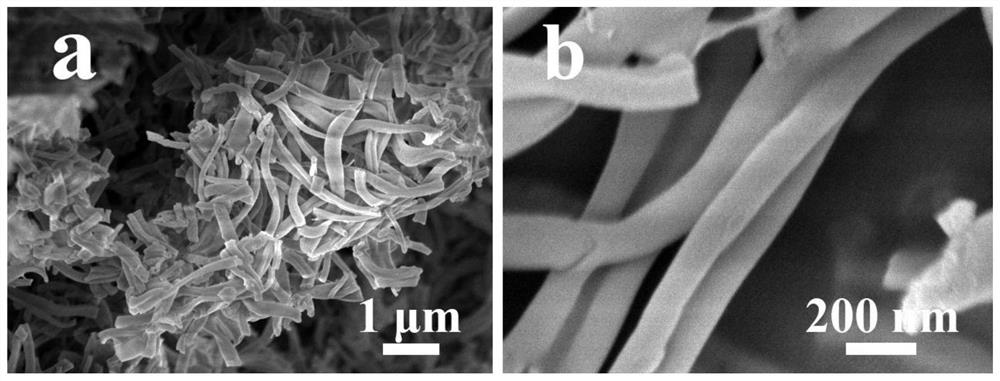

Embodiment 1

[0046] a Co 3 V 2 O 8 The preparation method of bifunctional electrocatalytic material comprises the following steps:

[0047] (1) 0.44g of cobalt nitrate hexahydrate, 0.12g of ammonium metavanadate and 1g of citric acid were dissolved in 14mL of deionized water, and then 1.5mL of hydrochloric acid with a mass concentration of 37wt% was added dropwise, and stirred for 120min to obtain a precursor solution.

[0048] (2) Weigh 0.8 g of polyvinylpyrrolidone (PVP) and dissolve it in 10 mL of absolute ethanol, and stir evenly; then add 2 mL of the precursor solution obtained in step (1) into it to obtain a precursor sol; place the obtained precursor sol in a The pressure is 20 kV, the relative humidity is 30%, electrospinning is performed at room temperature, the spinning receiving distance is 20 cm, and the advancing speed is 1 mL / h to obtain the precursor fiber.

[0049] (3) drying the precursor fiber obtained in step (2) at 40°C for 12 hours, then placing it in a tube furnace...

Embodiment 2

[0053] a Co 3 V 2 O 8 The preparation method of bifunctional electrocatalytic material comprises the following steps:

[0054] (1) 0.44g of cobalt nitrate hexahydrate, 0.12g of ammonium metavanadate and 1g of citric acid are dissolved in 14mL of deionized water, then 1.5mL of nitric acid with a mass concentration of 66wt% is added dropwise, and stirred for 120min to obtain a precursor solution;

[0055] (2) Weigh 1.2 g of polyvinylpyrrolidone (PVP) and dissolve it in 15 mL of absolute ethanol, and stir evenly; then add 3 mL of the precursor solution obtained in step (1) into it to obtain a precursor sol; place the obtained precursor sol in a The pressure is 25kV, the relative humidity is 30%, electrospinning is performed at room temperature, the spinning receiving distance is 15cm, and the advancing speed is 1.2mL / h, to obtain the precursor fiber.

[0056] (3) drying the precursor fiber obtained in step (2) at 50 °C for 16 h, then placing it in a tube furnace, heating up to...

Embodiment 3

[0058] a Co 3 V 2 O 8 The preparation method of bifunctional electrocatalytic material comprises the following steps:

[0059] (1) 0.5g of cobalt nitrate hexahydrate, 0.134g of ammonium metavanadate and 1.145g of citric acid were dissolved in 16mL of deionized water, and then 2mL of acetic acid with a mass concentration of 99wt% was added dropwise, and stirred for 150min to obtain a precursor solution;

[0060] (2) Weigh 0.9 g of polyvinylpyrrolidone (PVP) and dissolve it in 12 mL of absolute ethanol, and stir evenly; then add 2 mL of the precursor solution obtained in step (1) into it to obtain a precursor sol; place the obtained precursor sol in a The pressure is 20 kV, the relative humidity is 30%, electrospinning is performed at room temperature, the spinning receiving distance is 15 cm, and the advancing speed is 1 mL / h to obtain the precursor fiber.

[0061] (3) drying the precursor fiber obtained in step (2) at 60 °C for 12 h, then placing it in a tube furnace, heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com