Melamine cyanurate derivative covalent triazine framework flame retardant, preparation method and application thereof

A technology of melamine cyanurate and melamine cyanurate, which is applied in the field of melamine cyanurate derivative covalent triazine frame flame retardant and its preparation, can solve the problems affecting the compatibility of epoxy resin, Problems such as the decline in the mechanical properties of composite materials, to avoid side reactions, improve mechanical properties, reduce reaction costs and time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

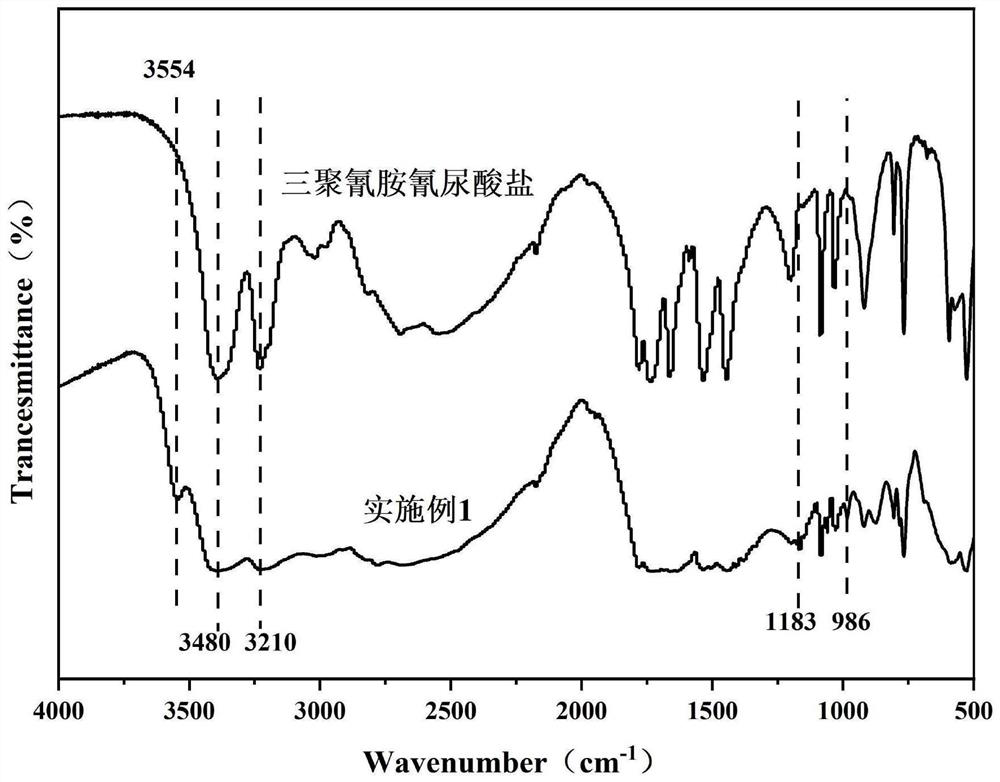

[0045] The preparation of melamine cyanurate derivative covalent triazine frame flame retardant specifically comprises the following steps:

[0046]Disperse 20.4g of melamine cyanurate into a three-necked flask filled with 100mL of tetrahydrofuran, place it in a water bath filled with ice cubes and stir, and control the temperature at 0-5°C. Then dissolve 5.7mL of phenylphosphoryl dichloride in 50mL of tetrahydrofuran, stir with a glass rod for 3-5min, and slowly drop the solution into the three-necked flask with a rubber dropper after dissolving. Ten minutes after the dropwise addition, 10 mL of triethylamine was added. After the addition of triethylamine, it was stirred at 0-5° C. for 6 h, and then the temperature was raised to 25° C. and stirred for 4 h.

[0047] Vacuum filter the mixed liquid after the reaction to obtain a precipitate, then fully wash with tetrahydrofuran, ethanol and deionized water to remove residual triethylamine, triethylamine hydrochloride and other i...

Embodiment 2

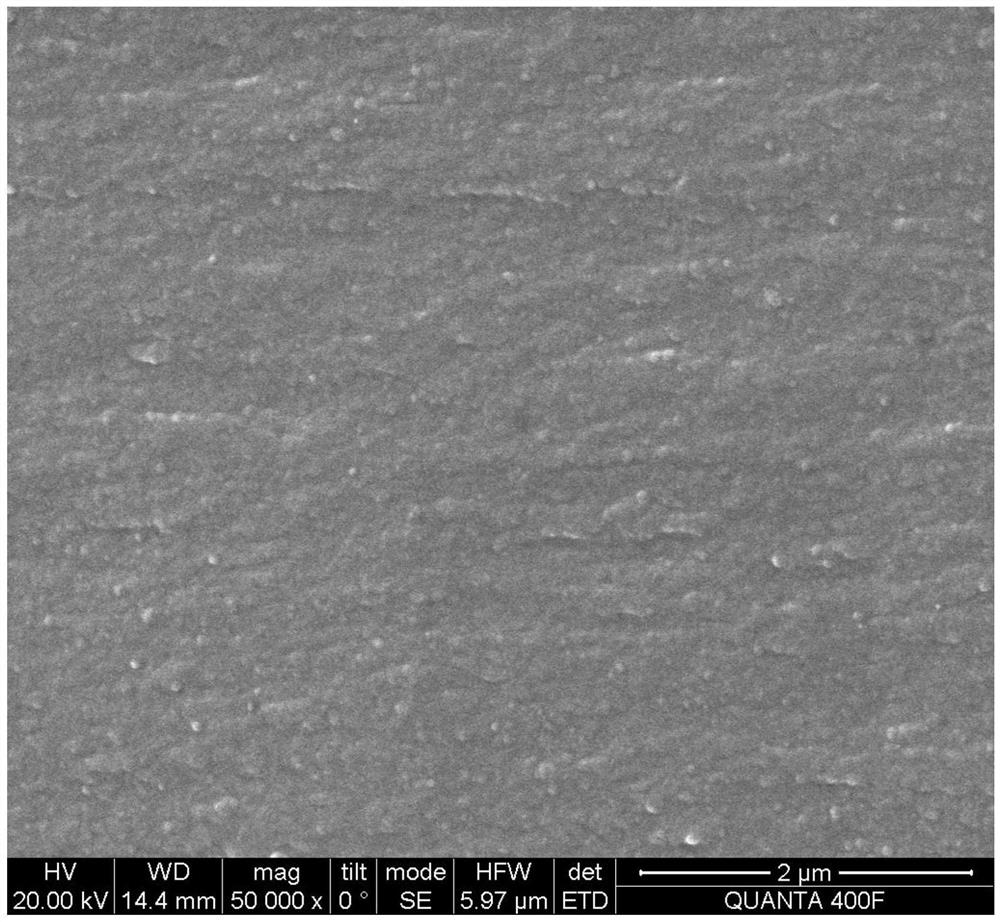

[0050] The preparation of the melamine cyanurate derivative covalent triazine frame flame-retardant epoxy resin composite material specifically comprises the following steps:

[0051] Preheat the epoxy resin in a blast oven for 15 minutes at a temperature of 85°C, then weigh 79.2g of epoxy resin and add them to 1g of melamine cyanurate derivative covalent triazine framework, and set the temperature at 80°C After stirring for 10 minutes under heating in a water bath, add 19.8g of 4,4-diaminodiphenylmethane respectively, and continue stirring for 10 minutes. After the stirring is completed, vacuumize to remove air bubbles, and then pour the mixture into a standard-sized polytetrafluoroethylene mold coated with silicone oil. , after being put into an oven for solidification, cooling and demoulding, and Example 2 was obtained. For comparison, pure epoxy resins were prepared. Add 25g of 4,4-diaminodiphenylmethane to 100g of epoxy resin, stir in a water bath at 80°C for 10min, then...

Embodiment 3

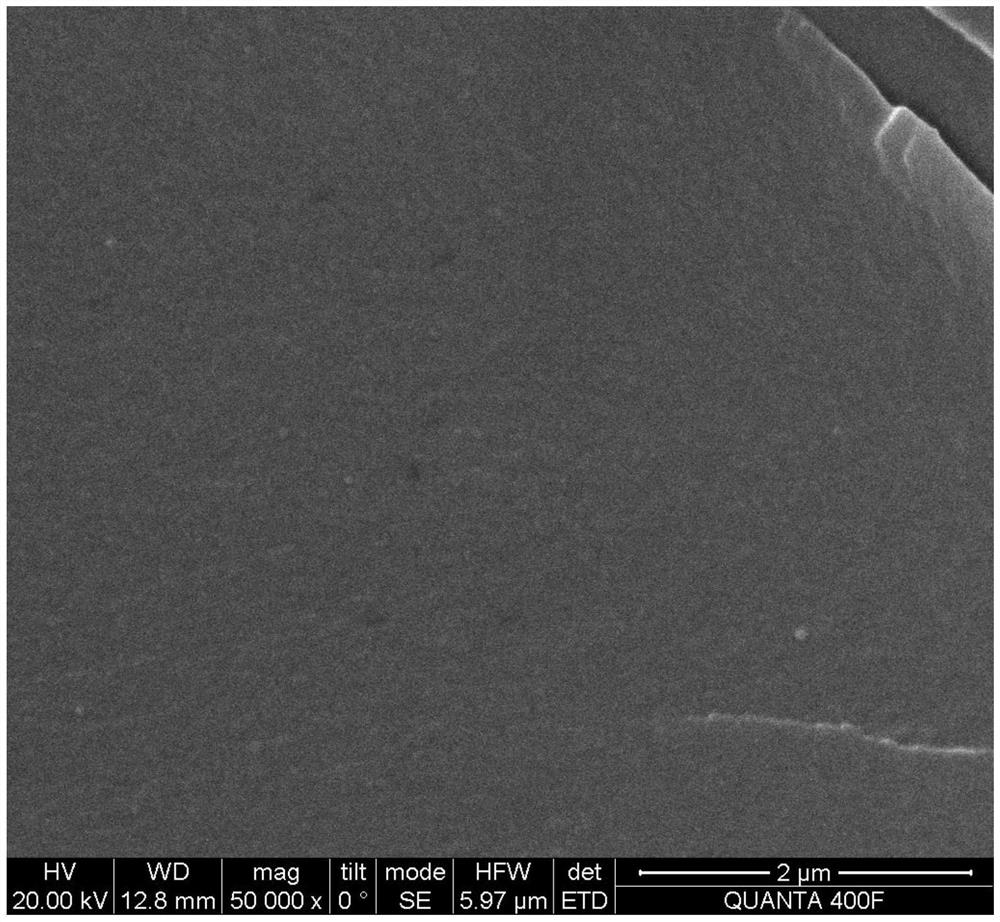

[0055] The preparation of the melamine cyanurate derivative covalent triazine frame flame-retardant epoxy resin composite material specifically comprises the following steps:

[0056] Place the epoxy resin in a blast oven for preheating for 15 minutes, and the oven temperature is 85°C, then weigh 76g of epoxy resin and add them to 5g of melamine cyanurate derivative covalent triazine frame flame retardant respectively. After heating and stirring in a water bath at 80°C for 10 minutes, add 19g of 4,4-diaminodiphenylmethane respectively, and continue stirring for 10 minutes. After the stirring is completed, vacuumize to remove air bubbles, and then pour the mixture into a standard-sized polytetrafluoroethylene mold coated with silicone oil. After being put into an oven for solidification, cooling and demoulding obtained Example 3, wherein the UL-94 test sample size was 130×13×3mm 3 .

[0057] The present invention only needs 5wt% melamine cyanurate derivatives covalent triazine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crimp elongation | aaaaa | aaaaa |

| crimp elongation | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com