Additive for flame-retardant adhesive as well as flame-retardant adhesive and application method thereof

A flame retardant adhesive and additive technology, which is applied in the directions of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc. The effect of increasing the scope of use, good mixing effect and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

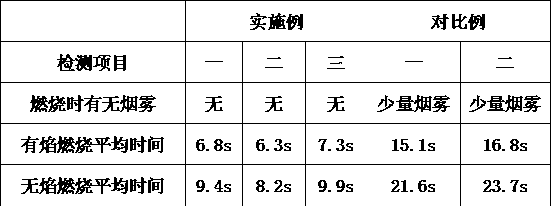

Examples

Embodiment 1

[0025] A kind of flame retardant glue proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of ethylene-vinyl acetate copolymer, 15 parts of polyurethane resin, 1.5 parts of glyceryl tristearate, 2 parts of flame retardant glue additives, antibacterial agent 0.5 parts, 2 parts of heat stabilizer, 50 parts of thinner, the flame retardant rubber additive includes the following raw materials in parts by weight: 2 parts of molybdenum trioxide, 4 parts of diatomaceous earth, 6 parts of mineral oil, 2 parts of silica gel powder, 0.5 parts of ethylene bis stearamide, 3 parts of polyethylene glycol;

[0026] Its preparation method comprises the following steps:

[0027] S1. First weigh each raw material according to 2 parts of molybdenum trioxide, 4 parts of diatomaceous earth, 6 parts of mineral oil, 2 parts of silica gel powder, 0.5 part of ethylene bis stearamide, and 3 parts of polyethylene glycol, and Molybdenum trioxide, diatomace...

Embodiment 2

[0033] A kind of flame-retardant glue proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of ethylene-vinyl acetate copolymer, 13 parts of polyurethane resin, 1 part of glyceryl tristearate, 3 parts of flame-retardant glue additive, bacteriostat 0.3 parts, 2 parts of heat stabilizer, 40 parts of diluent, the flame retardant rubber additive includes the following raw materials in parts by weight: 2 parts of molybdenum trioxide, 4 parts of diatomaceous earth, 6 parts of mineral oil, 2 parts of silica gel powder, 1 part of ethylene bis stearamide, 2 parts of polyethylene glycol;

[0034] Its preparation method comprises the following steps:

[0035] S1, first weigh each raw material according to 2 parts of molybdenum trioxide, 4 parts of diatomaceous earth, 6 parts of mineral oil, 2 parts of silica gel powder, 1 part of ethylene bisstearamide, and 2 parts of polyethylene glycol, and Molybdenum trioxide, diatomaceous earth, minera...

Embodiment 3

[0041] A kind of flame-retardant glue proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of ethylene-vinyl acetate copolymer, 10 parts of polyurethane resin, 1.5 parts of glyceryl tristearate, 5 parts of flame-retardant glue additives, antibacterial agent 0.1 part, 2 parts of heat stabilizer, 30 parts of diluent, the flame retardant rubber additive includes the following raw materials in parts by weight: 3 parts of molybdenum trioxide, 6 parts of diatomaceous earth, 5 parts of mineral oil, 1 part of silica gel powder, 0.5 parts of ethylene bis stearamide, 3 parts of polyethylene glycol;

[0042] Its preparation method comprises the following steps:

[0043] S1, first weigh each raw material according to 3 parts of molybdenum trioxide, 6 parts of diatomaceous earth, 5 parts of mineral oil, 1 part of silica gel powder, 0.5 part of ethylene bisstearamide, and 3 parts of polyethylene glycol, and Molybdenum trioxide, diatomaceous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com