Preparation method and application of novel modified polylactic acid

A polylactic acid and modification technology, which is applied in the field of preparation of new modified polylactic acid, can solve the problems of film bubble instability, low melt strength, hardening, etc., and achieve the effect of promoting environmental protection and improving mechanical and optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

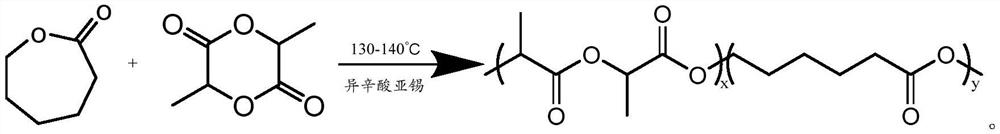

[0026] A kind of preparation method of novel modified polylactic acid, comprises the steps:

[0027] Step 1. Weigh L-lactide and ε-caprolactone according to the molar ratio of 1:2.5, put them into a two-necked flask, and then add stannous isooctanoate with a total mass fraction of 0.1% as a catalyst. The reaction was carried out under nitrogen atmosphere for 24 h to obtain the crude product. Dissolve the crude product in chloroform at room temperature, add methanol solution to precipitate, repeat the purification 3 times and place it in a vacuum oven at 50°C to dry to obtain the final product grafted caprolactone-lactic acid copolymer;

[0028] Step 2. Weigh 1 g of the caprolactone-lactic acid copolymer obtained in step 1 and 99 g of polylactic acid, and use a torque rheometer to perform melt blending, and blend for 5 min at 180 ° C and a speed of 50 r / min to obtain a blend ;

[0029] Step 3. Vacuum-dry 99.5 g of the blend obtained in Step 2 and 0.5 g of long-lasting lumines...

Embodiment 2

[0031] A kind of preparation method of novel modified polylactic acid, comprises the steps:

[0032] Step 1. Weigh L-lactide and ε-caprolactone according to the molar ratio of 1:2.6, put them into a two-necked flask, and then add stannous isooctanoate with a total mass fraction of 0.2% as a catalyst, at 110°C, The reaction was carried out under nitrogen atmosphere for 21 h to obtain the crude product. Dissolve the crude product in chloroform at room temperature, add methanol solution to precipitate, repeat the purification 4 times and place it in a vacuum oven at 60°C to dry to obtain the final product grafted caprolactone-lactic acid copolymer;

[0033] Step 2. Weigh 5 g of caprolactone-lactic acid copolymer and 95 g of polylactic acid obtained in step 1, melt blend them with a torque rheometer, and blend them for 6 minutes at 185 ° C and a speed of 50 r / min to obtain a blend ;

[0034] Step 3. Vacuum-dry 99.5 g of the blend obtained in Step 2 and 0.5 g of long-lasting lumi...

Embodiment 3

[0036] A kind of preparation method of novel modified polylactic acid, comprises the steps:

[0037] Step 1. Weigh L-lactide and ε-caprolactone according to the molar ratio of 1:2.5, put them into a two-necked flask, and then add stannous isooctanoate with a total mass fraction of 0.17% as a catalyst. The reaction was carried out under nitrogen atmosphere for 22 h to obtain the crude product. Dissolve the crude product in chloroform at room temperature, add methanol solution to precipitate, repeat the purification 4 times, and place it in a vacuum oven at 50°C to dry to obtain the final product grafted caprolactone-lactic acid copolymer;

[0038] Step 2. Weigh 10 g of the caprolactone-lactic acid copolymer and 90 g of polylactic acid obtained in step 1, melt blend them using a torque rheometer, and blend them for 8 minutes at 190°C and a speed of 50 r / min to obtain a blend ;

[0039] Step 3. Vacuum-dry 98 g of the blend obtained in Step 2 and 2 g of long-lasting luminous pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com