Innovative process for molding tender shoots of vine tea

A technology for rattan tea and tender buds, which is applied in the field of innovative technology for forming rattan tea tender buds, can solve the problems of inconvenient portability and transportation, increased volume, and large volume, and achieves reduction of packaging production and road transportation costs, small size, Guaranteed Integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

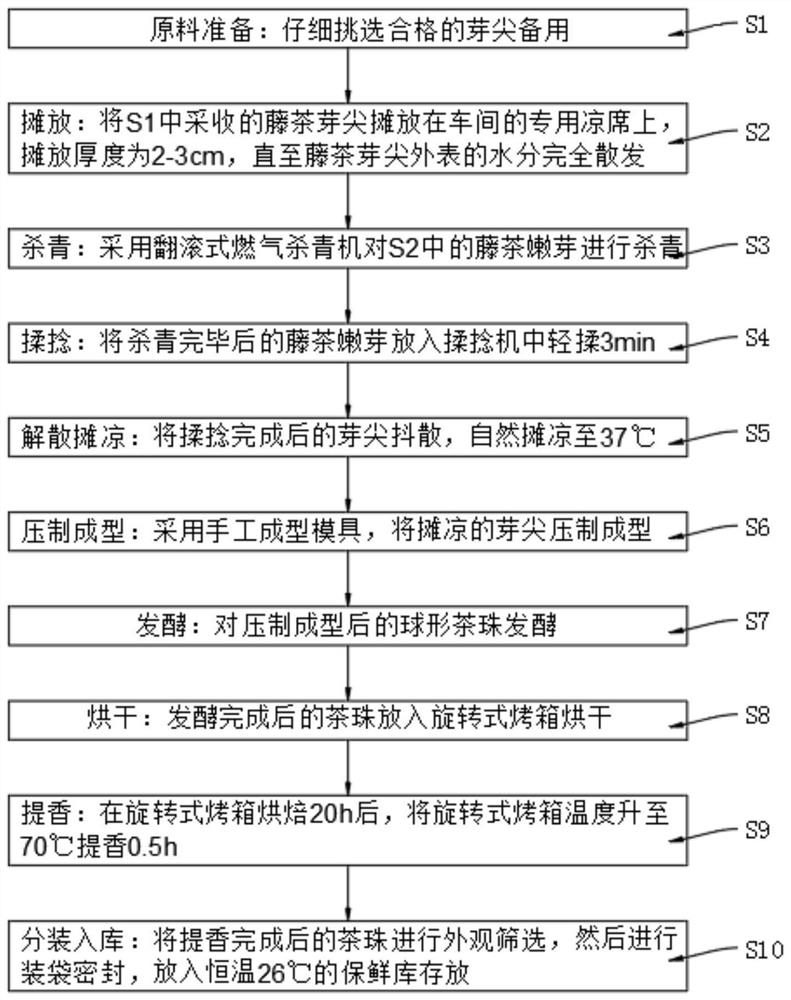

[0044] Please refer to figure 1 As shown, the innovative process of forming the buds of rattan tea comprises the following steps:

[0045] Step 1. Raw material preparation: carefully select qualified bud tips for later use.

[0046] Selecting qualified bud tips refers to harvesting 4-5cm vine tea bud tips in the morning, and selecting vine tea bud tips that are free from disease, insect damage, and damage.

[0047] Step 2. Spreading: Spread the vine tea bud tips harvested in step 1 on a special mat in the workshop, with a thickness of 2 cm, until the moisture on the surface of the vine tea bud tips is completely dispersed.

[0048] Step 3, greening: use a tumbling gas greening machine to kill the green shoots of the rattan tea in step 2.

[0049] Adopt tumbling type gas greening machine to carry out greening to the vine tea tender shoot in step 2, comprise the following steps:

[0050] 301), the tumbling gas greening machine is opened.

[0051] 302), after raising the temp...

Embodiment 2

[0068] The vine tea tender shoot forming innovation process provided by the present embodiment is roughly the same as that of embodiment 1, and its main difference is:

[0069] In step 2, the thickness of spreading is 3cm, until the moisture on the surface of the bud tip of the vine tea is completely dissipated.

[0070] The present invention is based on the traditional craft of making rattan tea, combined with the characteristics of rattan tea, through the natural cooling technology of this craft, it is more scientific and reasonable than the original traditional craft, and the unique fragrance and fragrance of rattan tea are retained in the natural cooling process. The fresh soup color avoids the bitter taste and turbid soup color caused by traditional crafts. The technology of SUS304 stainless steel tube mold pressing can ensure the integrity of the buds of rattan tea. Compared with traditional crafts, it is not fragile, small in size and easy to carry. The advantage of tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com