Temperature-resistant and moisture-resistant epoxy pouring sealant for hydrogen energy fuel cell humidifier and preparation method of temperature-resistant and moisture-resistant epoxy pouring sealant

A fuel cell and humidifier technology, which is applied to fuel cells, epoxy resin glue, electrochemical generators, etc., can solve the problems of inability to meet the proton membrane humidifier, proton membrane failure, etc., and achieve good high temperature and high humidity resistance. , The effect of improving temperature resistance and improving toughness

Active Publication Date: 2022-01-28

DOCBOND TECH DEV CO LTD

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005]The proton membrane plays a vital role in the whole hydrogen fuel cell, and the organic substances such as N and S and the ionized substances such as Sn, Pb, Hg, Bi and As It will make the proton membrane invalid, so the curing agents (amines, imidazoles, etc.) used in general epoxy resins cannot meet the requirements of the proton membrane and humidifier

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention, but this does not limit the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

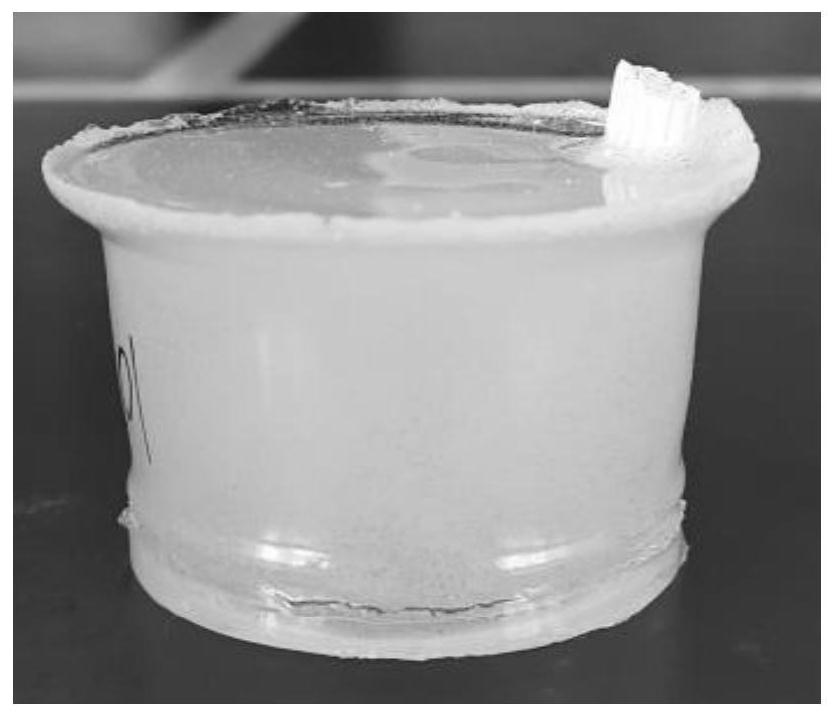

The invention discloses a temperature-resistant and moisture-resistant epoxy pouring sealant for a hydrogen energy fuel cell humidifier , the epoxy pouring sealant is prepared by mixing a component A and a component B according to a certain proportion, the component A comprises the following components in parts by weight: 80-90 parts of epoxy resin, 10-20 parts of toughened resin and 0-2 parts of a surfactant; the epoxy resin is a mixture of m-xylenol formaldehyde epoxy resin, hydrogenated bisphenol A epoxy resin and organic titanium epoxy resin; the toughened resin is one or more of organic silicon modified epoxy resin, polyether epoxy resin, acrylic rubber modified epoxy resin and carboxyl-terminated liquid nitrile rubber; and the component B is a curing agent, and the curing agent is one or more of an SP multifunctional epoxy curing agent, FB high-temperature-resistant flame-retardant thermosetting phenolic resin and liquid anhydride. The pouring sealant disclosed by the invention has good temperature resistance and moisture resistance, can resist 100-110 DEG C for a long time, has very good adhesive force to an LCP (Liquid Crystal Polymer) shell, and most importantly, does not cause failure of a proton membrane.

Description

technical field [0001] The invention relates to the technical field of compound preparation, in particular to a heat-resistant and moisture-resistant epoxy potting glue for a hydrogen energy fuel cell humidifier and a preparation method thereof. Background technique [0002] Hydrogen fuel cell is a clean, efficient and long-life power generation device. Compared with conventional power generation technologies, hydrogen fuel cells have great advantages in terms of efficiency, safety, reliability, flexibility, cleanliness, and operational performance, and have broad application prospects. The principle of the hydrogen energy fuel cell: H2 passes through the anode carbon fiber diffusion layer in a gaseous state, and is separated into H protons and electrons in the catalytic layer, and the H protons (in the state of H3O+) pass through the proton exchange membrane, and combine with O ions in the cathode catalytic layer to form water. . The proton exchange membrane can only pass...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J163/04C09J163/02C09J163/00C09J11/08C08G59/42H01M8/04119

CPCC09J163/04C09J11/08C08G59/4284C08G59/4071H01M8/04126C08L2201/08C08L2203/20C08L2205/025C08L2205/035C08L63/00C08L13/00C08L83/04Y02E60/50

Inventor 郑健保赖育南李锦青莫华

Owner DOCBOND TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com