Catalyst carrier for preparing high energy density fuel, preparation method and application

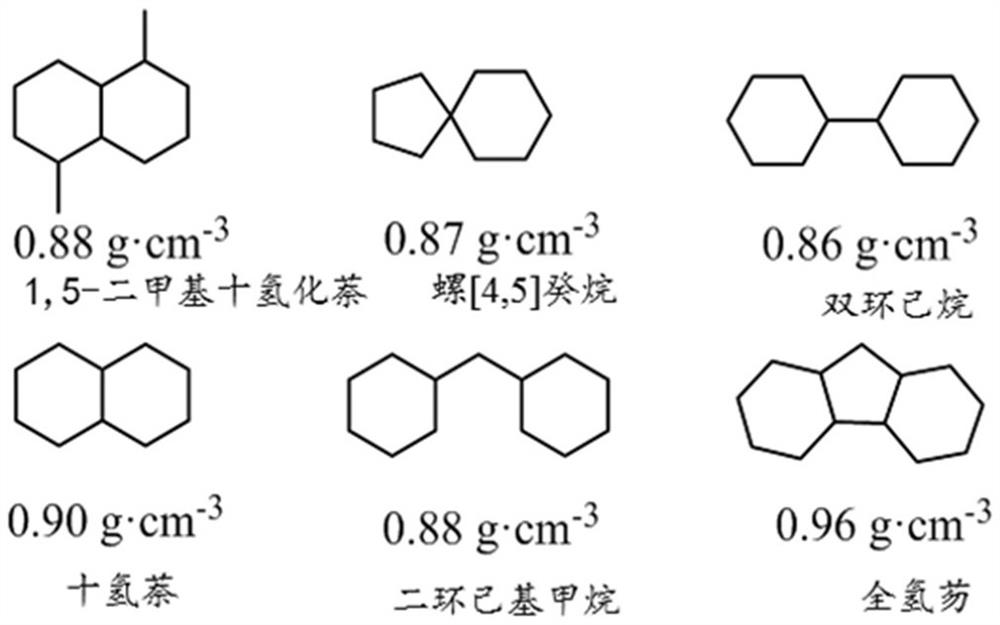

A technology with high energy density and catalyst, which is applied in the direction of catalyst carrier, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of not having high specific surface area and single catalyst function, so as to improve the performance of hydrodeoxygenation and benzene Effects of ring saturation, increased added value, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

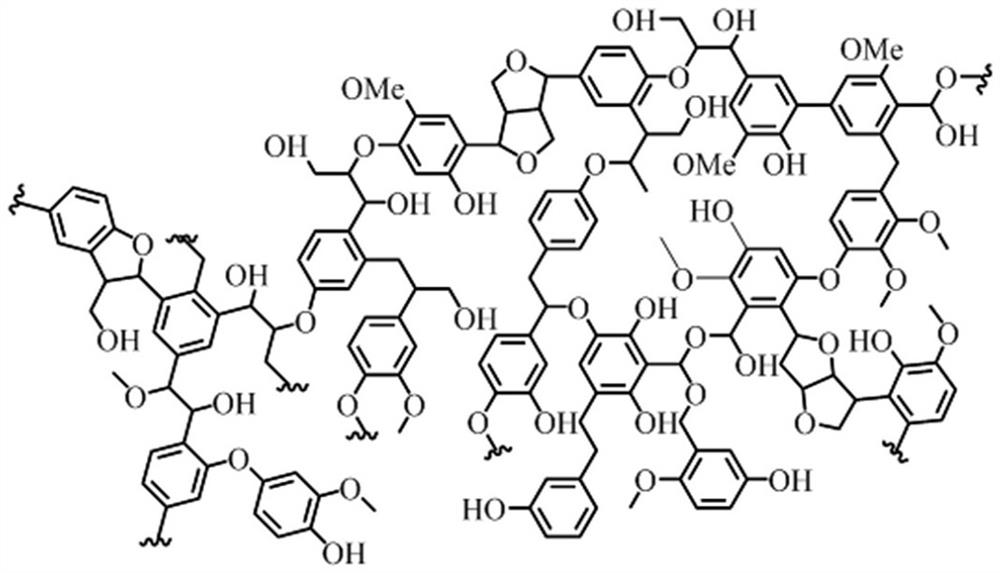

Method used

Image

Examples

Embodiment 1-9

[0065] Examples 1-9 provide one Nb / ZrO, respectively 2 Catalyst carrier and preparation method thereof, the preparation method comprises the following steps,

[0066] (1) Zirconium nitrate, stabilizer and 100mL ethanol are mixed to form solution A; niobium oxalate and 100mL aqueous oxalic acid solution are mixed to form solution B; template agent and 100mL ethanol are mixed to form solution C;

[0067] (2) Solution A and solution B are added to solution C at the same time, to obtain a mixed solution, add ammonia in the mixed solution to adjust the pH to 3-6, stir the reaction at 25 ° C, take it out and filter, dry it at 100 ° C for 10h, and then calcinate for 6h to give Nb-doped ZrO 2 Catalyst carrier, denoted Nb / ZrO 2 。

[0068] The difference between Examples 1-9 is that the molar concentration of zirconium ions in the mixed solution in the preparation catalyst support, the mass concentration of the stabilizer in the mixed solution, the molar concentration of niobium ions in th...

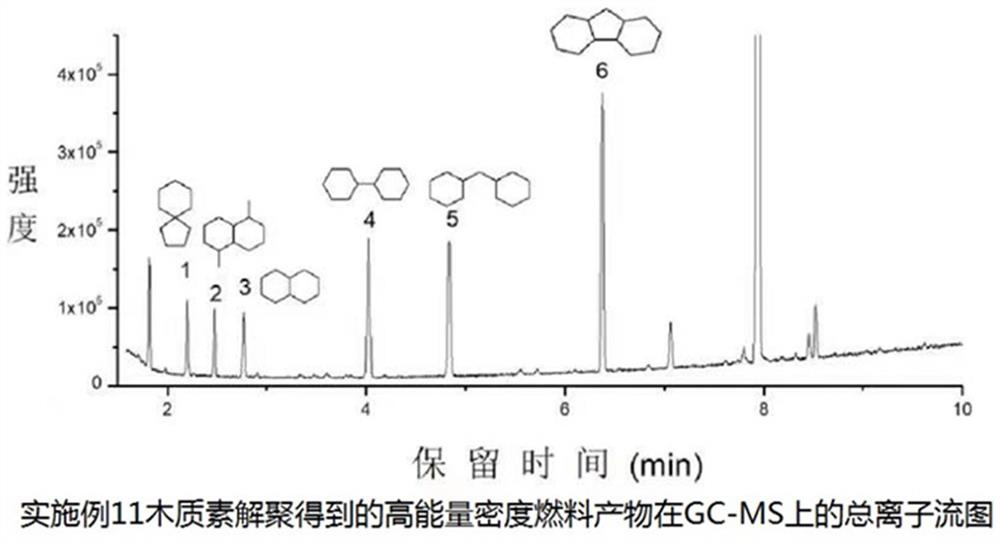

Embodiment 10-20

[0075] Examples 10-20 respectively provide a method for preparing a high energy density fuel, comprising the following steps,

[0076] The lignin and catalyst were dispersed in 100mL of water, and then placed in a 300mL high-pressure reactor, into which 0.5-5MPa of hydrogen was poured, heated to 250-350 °C, stirred reaction for 0.5-12h, after the end of the reaction, filtration, rotary distillation to remove the solvent, to obtain high energy density fuel.

[0077] Wherein, the difference between Example 10-20 is that the amount of lignin, the amount of catalyst, the type of catalyst, the hydrogen pressure, the reaction temperature, the reaction time are different, the process parameters in Example 10-20 are shown in Table 2.

[0078] Table 2 Process parameters in Example 10-20

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com