Modified fluorosilicone acrylate resin, antifouling and antibacterial coating and preparation method thereof

A technology of fluorosilicon acrylate and antibacterial coatings, which is applied in the field of preparation of modified fluorosilicon acrylate resins, antifouling and antibacterial coatings, modified fluorosilicon acrylate resins and antifouling and antibacterial coatings, and can solve difficult to deal with complex realities Environmental, inorganic or organic single antibacterial methods and other issues, to achieve the effect of outstanding antifouling performance and good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

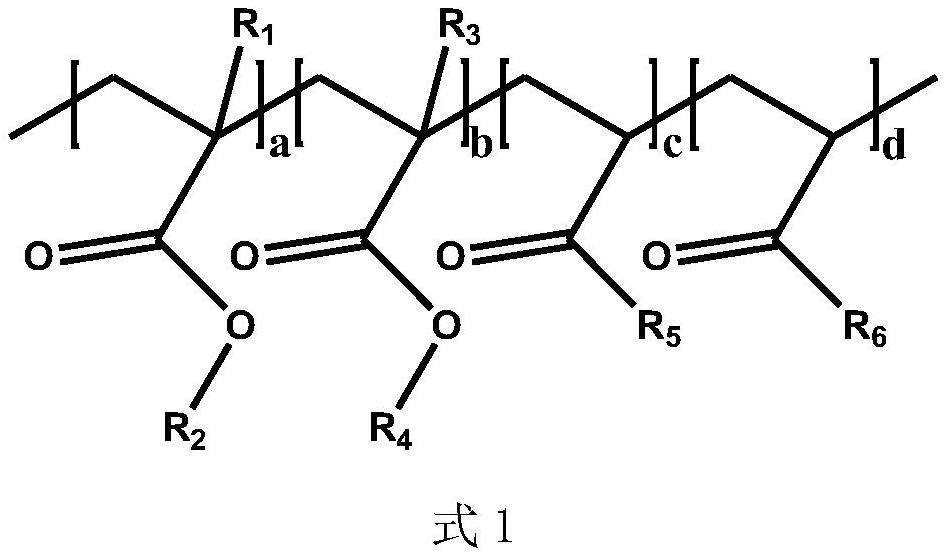

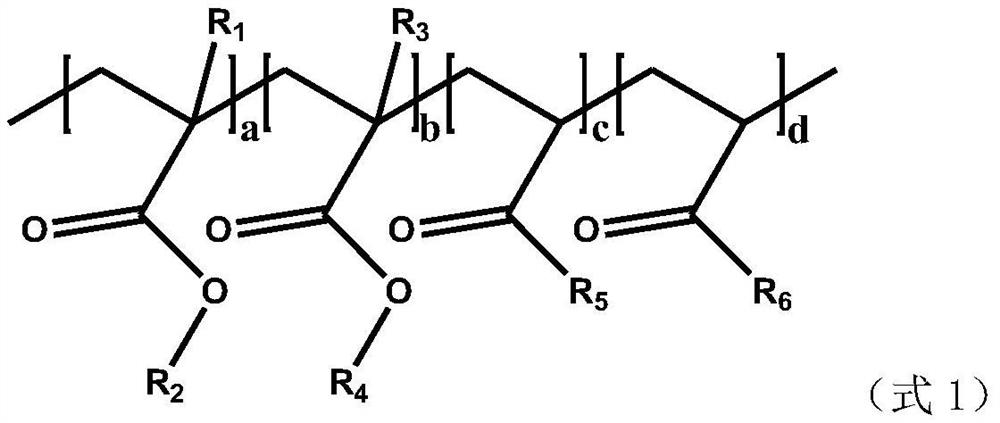

Method used

Image

Examples

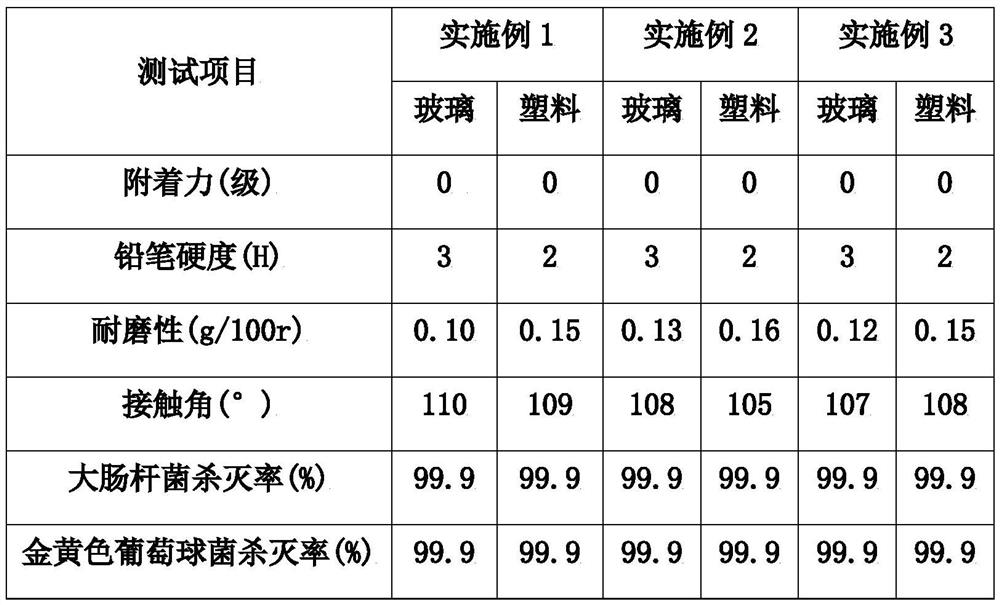

Embodiment 1

[0030] First carry out the preparation of antibacterial modified fluorosilicone acrylate resin:

[0031] (1) Dissolve 20g of methyl methacrylate, 15g of acrylic acid, 20g of n-butyl acrylate, and 5g of hexafluorobutyl methacrylate in an equal-volume mixed solvent of 800ml of butyl acetate and cyclohexanone, stir and feed Nitrogen for 1 h, 0.2 g of azobisisobutyronitrile was added, and the reaction was stirred at 45° C. for 24 h.

[0032] (2) After natural cooling, the reaction solution was concentrated and poured into a large amount of n-hexane for precipitation, washed with ethanol and centrifuged for three times, and dried in an oven at 80°C for 12 hours.

[0033] (3) Redissolve 10g of the initial product in 150ml of an equal ratio mixed solvent of butyl acetate and cyclohexanone, add 0.5g of 4-dimethylaminopyridine and 1g of 1-(3-dimethylaminopropyl)-3-ethyl Carbodiimide hydrochloride, drop a few drops of triethylamine, add 10g of 4-pyridineformyl biguanide after stirring ...

Embodiment 2

[0039] First carry out the preparation of antibacterial modified fluorosilicone acrylate resin:

[0040] (1) Dissolve 20g of methyl methacrylate, 20g of acrylic acid, 20g of n-butyl acrylate, 10g of perfluoromethyl ethyl acrylate in 1000ml of butyl acetate, cyclohexanone and methyl isobutyl ketone in an equal volume mix In the solvent, stir and blow nitrogen gas for 1 h, add 0.2 g of azobisisobutyronitrile, and stir and react at 40° C. for 36 h.

[0041] (2) After natural cooling, the reaction solution was concentrated and poured into a large amount of n-hexane for precipitation, washed with ethanol and centrifuged for three times, and dried in an oven at 80°C for 12 hours.

[0042] (3) Redissolve 10 g of the initial product in a mixed solvent, add 0.5 g of N-methylmorpholine and 1 g of 3-diethoxyphosphoryl-1,2,3-oxazol 4(3H)-one in sequence, drop Add a few drops of triethylamine, stir for 1 hour, add 10 g of 4-pyridineformyl biguanide, react at 40°C for 8 hours, then add 10 ...

Embodiment 3

[0048] First carry out the preparation of antibacterial modified fluorosilicone acrylate resin:

[0049] (1) 20g methyl methacrylate, 20g acrylic acid, 20g n-butyl acrylate, 5g perfluoropropyl ethyl acrylate are dissolved in the equal volume mixed solvent of 1000ml butyl acetate and methyl isobutyl ketone, stir Nitrogen gas was introduced for 1 h, 0.2 g of azobisisobutyronitrile was added, and the reaction was stirred at 50° C. for 18 h.

[0050] (2) After natural cooling, the reaction solution was concentrated and poured into a large amount of n-hexane for precipitation, washed with ethanol and centrifuged for three times, and dried in an oven at 80°C for 12 hours.

[0051] (3) Redissolve 10 g of the initial product in a mixed solvent, add 0.5 g of N-methylmorpholine and 1 g of 2-(7-azabenzotriazole)-N,N,N',N'-tetra Add a few drops of triethylamine to methylurea hexafluorophosphate, stir for 1 hour, add 15g of 3-pyridineformyl biguanide, react at 40°C for 12 hours, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com