Preparation method of photocuring hydrogel microspheres capable of promoting angiogenesis

A technology of hydrogel microspheres and angiogenesis, which is applied in prosthetics, medical science, etc., can solve the problems of inability to achieve sustained release and inability to effectively control the degradation rate, and achieve excellent adjustable mechanical properties and excellent biological properties. compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

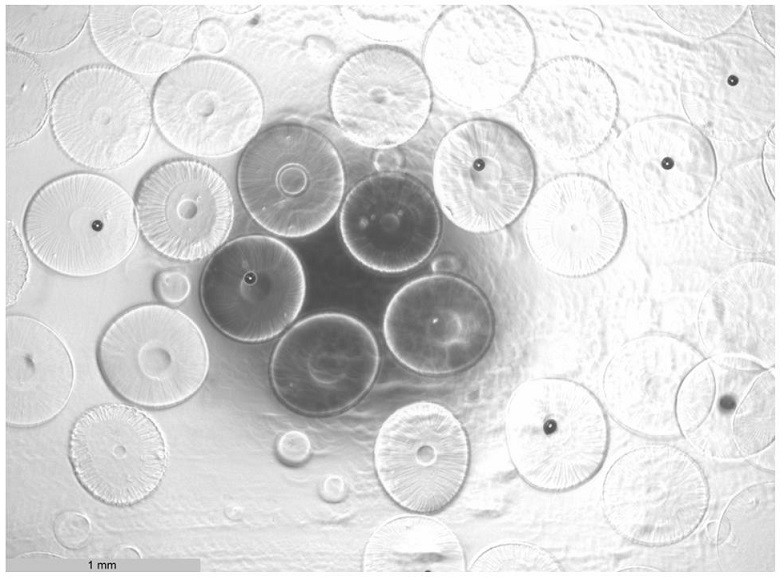

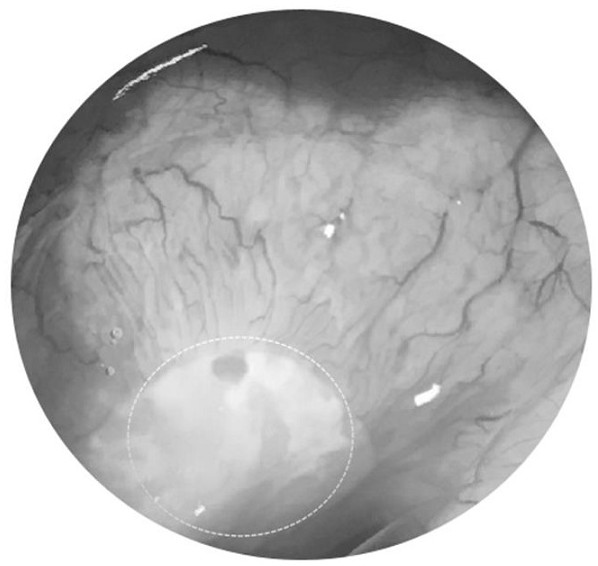

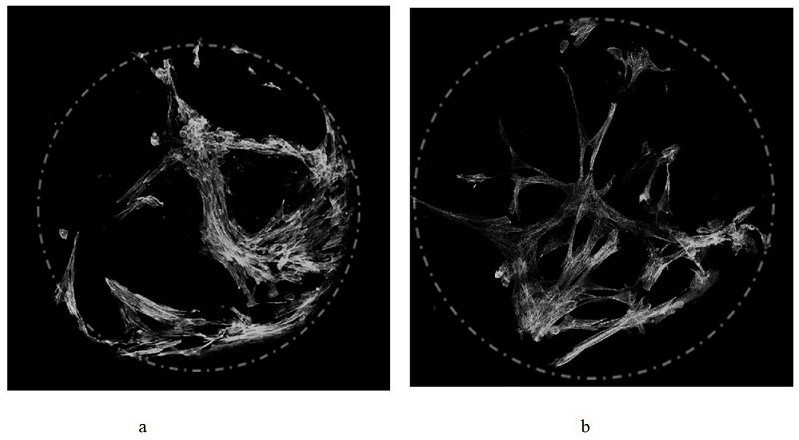

[0030] A method for preparing photocurable hydrogel microspheres that can promote angiogenesis, specifically comprising the following steps:

[0031] (1) Add sodium carbonate to the obtained deionized water, dilute and adjust the pH to 7.4, add gelatin to the sodium carbonate solution at a ratio of 100g / L, stir and dissolve at 50°C, then add methacrylic anhydride, methyl The volume mass ratio of acrylic anhydride to gelatin is 2:1. After the reaction is completed, dialyze with deionized water at room temperature for 5 days, change the water every 12 hours, and the molecular weight cut-off of the dialysis bag is 8KDa-14Kda. Acrylic acylated gelatin.

[0032] (2) Dissolve methacrylic acylated gelatin in deionized water at a ratio of 100g / L, then add succinic anhydride, the volume-to-mass ratio of succinic anhydride to methacrylic acylated gelatin is 1:1.6. Stir and react for 24 hours; after the reaction is completed, dialyze with deionized water at room temperature for 5 days, ...

Embodiment 2

[0052] A method for preparing photocurable hydrogel microspheres that can promote angiogenesis, specifically comprising the following steps:

[0053] (1) Add sodium carbonate to the obtained deionized water, dilute and adjust the pH to 8, add gelatin to the sodium carbonate solution at a ratio of 50g / L, stir and dissolve at 35°C, then add methacrylic anhydride, methyl The volume mass ratio of acrylic anhydride to gelatin is 1:1. After the reaction is completed, dialyze with deionized water at room temperature for 5 days, change the water every 12 hours, and the molecular weight cut-off of the dialysis bag is 8KDa-14Kda. Acrylic acylated gelatin.

[0054] (2) Dissolve methacrylic acid acylated gelatin in deionized water at a ratio of 50g / L, then add succinic anhydride, the volume-mass ratio of succinic anhydride to methacrylic acid acylated gelatin is 1:1, at 25°C Stir and react for 24 hours; after the reaction is completed, dialyze with deionized water at room temperature for...

Embodiment 3

[0061] A method for preparing photocurable hydrogel microspheres that can promote angiogenesis, specifically comprising the following steps:

[0062] (1) Add sodium carbonate to the obtained deionized water, dilute and adjust the pH to 10, add gelatin to the sodium carbonate solution at a ratio of 200g / L, stir and dissolve at 60°C, then add methacrylic anhydride, methyl The volume mass ratio of acrylic anhydride to gelatin is 3:1. After the reaction is completed, use deionized water to dialyze at room temperature for 5 days, and change the water every 12 hours. The molecular weight cut-off of the dialysis bag is 8KDa-14Kda. Acrylic acylated gelatin.

[0063] (2) Dissolve methacrylic acid acylated gelatin in deionized water at a ratio of 200g / L, then add succinic anhydride, the volume mass ratio of succinic anhydride to methacrylic acid acylated gelatin is 1:3, at 55℃ Stir and react for 24 hours; after the reaction is completed, dialyze with deionized water at room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com