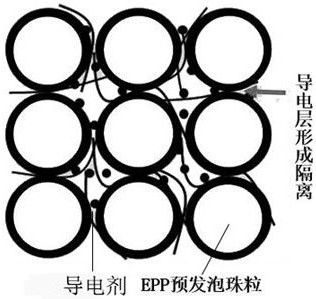

Preparation method of conductive EPP foam with isolation structure

An isolation structure and foam technology, which is applied in the field of conductive and electromagnetic shielding materials, can solve problems such as limited foaming ratio and molding process challenges, and achieve good shielding performance, simple process, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: a kind of preparation method of the conductive EPP foam with isolation structure, it may further comprise the steps:

[0025] S1. Preparation of conductive paste: add conductive agent, liquid high molecular polymer and additives into a high-speed disperser for dispersion. The speed of the high-speed disperser is 400 r / min. After dispersing for 1 hour, take out the paste and let it stand for 1 hour Carry out defoaming afterward, make conductive paste;

[0026] Wherein, the conductive agent is a mixture of graphite, nickel-coated carbon fiber carbon black, iron powder and flake iron-nickel alloy powder in any proportion; the liquid polymer is polyurethane resin, ethylene-vinyl acetate copolymer and water-soluble modified The mixing of polypropylene in any proportion; the auxiliary agent is the mixing of dispersant, wetting agent, thickener and defoamer;

[0027] In the conductive paste, the mass fraction of the solid content of the liquid polymer is 0.1%, t...

Embodiment 2

[0030] Embodiment 2: a kind of preparation method of the conductive EPP foam with isolation structure, it may further comprise the steps:

[0031] S1. Preparation of conductive paste: Add conductive agent, liquid high molecular polymer and additives into a high-speed disperser for dispersion. The speed of the high-speed disperser is 600 r / min. After dispersing for 1 hour, take out the paste and let it stand for 1 hour Carry out defoaming afterward, make conductive paste;

[0032] Wherein, the conductive agent is a mixture of carbon nanofibers, graphite nanosheets, graphene and flake iron-based metal powder in any proportion; the liquid polymer is acrylic resin, epoxy resin and styrene-acrylic emulsion in any proportion Mixing; the auxiliary agent is a dispersant, a wetting agent, a thickener and a defoamer;

[0033] In the conductive paste, the mass fraction of the solid content of the liquid polymer accounts for 30%; the mass fraction of the solid content of the dispersant a...

Embodiment 3

[0036] Embodiment 3: a kind of preparation method of the conductive EPP foam with isolation structure, it may further comprise the steps:

[0037]S1. Preparation of conductive paste: Add conductive agent, liquid high molecular polymer and additives into a high-speed disperser for dispersion. The speed of the high-speed disperser is 500 r / min. After dispersing for 1 hour, take out the paste and let it stand for 1 hour Carry out defoaming afterward, make conductive paste;

[0038] Wherein, the conductive agent is nickel-coated carbon fiber carbon black; the liquid polymer is a mixture of epoxy resin and polyvinylpyrrolidone with a weight ratio of 1:2; the auxiliary agent is a dispersant, a wetting agent, a thickener agent and defoamer;

[0039] In the conductive paste, the mass fraction of the solid content of the liquid polymer is 12%; the mass fraction of the solid content of the dispersant is 1%, and the mass fraction of the solid content of the wetting agent is 0.8%. The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com