Damping low-smoke halogen-free flame-retardant CR foam double-faced adhesive tape, and preparation and application thereof

A double-sided adhesive and double-sided technology, applied in adhesives, film/sheet adhesives, adhesive additives, etc., can solve the problem that double-sided adhesives cannot meet the requirements of flame retardancy, shock absorption, light weight, and shock absorption and buffering capabilities Limited and other problems, to achieve good foaming uniformity and mechanical strength, improve flame retardancy, and good shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

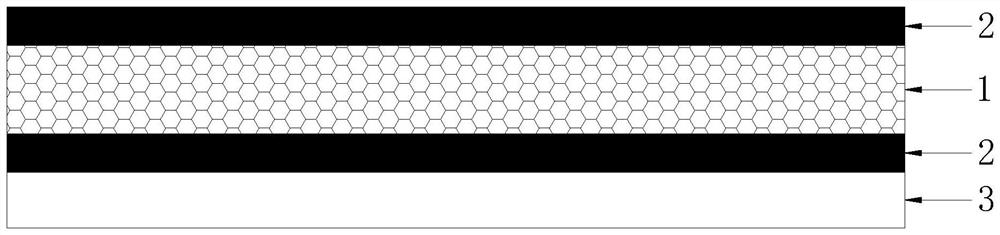

[0039] A shock-absorbing, low-smoke, halogen-free, flame-retardant CR foam double-sided adhesive of this embodiment has a schematic diagram of its laminated structure as shown in figure 1 shown. Including the halogen-free flame-retardant CR foam carrier layer 1, the halogen-free flame-retardant CR foam carrier layer 1 is covered with a thermally conductive halogen-free flame-retardant acrylate adhesive layer 2, and one side is covered with a thermally conductive halogen-free flame-retardant acrylate adhesive layer 2 A release film 3 is also attached, and the release film adopts double-plastic double-silicon release paper. The thickness of the halogen flame-retardant CR foam carrier layer in this embodiment can be adjusted in the range of 0.5mm-1mm; the thickness of the heat-conducting halogen-free flame-retardant acrylate adhesive layer can be adjusted in the range of 0.05mm-0.1mm.

[0040] A shock-absorbing, low-smoke, halogen-free, flame-retardant CR foam double-sided adhes...

Embodiment 2

[0053] A shock-absorbing, low-smoke, halogen-free, flame-retardant CR foam double-sided adhesive of this embodiment is prepared by the following method:

[0054] (1) Preparation of halogen-free flame-retardant CR foam:

[0055] 1) Add IFR powder (consisting of acid source ammonium polyphosphate, gas source melamine polyphosphate and carbon source triazine macromolecular char forming agent) into silica sol and mix evenly. The amount of silica sol added is based on solid content It is 5% of the mass of the IFR powder, and then 0.2% of the mass of the IFR powder is added with vinyltrimethoxysilane for surface modification, vacuum-dried and pulverized to obtain a surface-modified IFR flame retardant.

[0056] 2) In parts by weight, 40 parts of chloroprene rubber, 1 part of stearic acid and 6 parts of naphthenic oil are added into a mixer and mixed evenly, and the mixing temperature is controlled at 85-95°C.

[0057] 3) Put the mixed material of step 2) into the banbury mixer for ...

Embodiment 3

[0066] A shock-absorbing, low-smoke, halogen-free, flame-retardant CR foam double-sided adhesive of this embodiment is prepared by the following method:

[0067] (1) Preparation of halogen-free flame-retardant CR foam:

[0068] 1) Add IFR powder (composed of acid source aluminum diethyl hypophosphite, gas source melamine polyphosphate and carbon source pentaerythritol) into the silica sol and mix evenly. The amount of silica sol added is IFR powder in terms of solid content. 30% of the mass of the material, and then add vinyltrimethoxysilane of 2% of the mass of the IFR powder to modify the surface, dry in vacuum, and pulverize to obtain a surface-modified IFR flame retardant.

[0069] 2) In parts by weight, 55 parts of chloroprene rubber, 2 parts of stearic acid and 3 parts of naphthenic oil are added into the mixer and mixed evenly, and the mixing temperature is controlled at 85-95°C.

[0070] 3) Put the mixed material of step 2) into the internal mixer and banbury for 3 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com