Solid-state electrolyte and solid-state battery containing same

A solid-state electrolyte and battery technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, solid electrolytes, etc. It can solve the problems that all solid-state lithium-ion batteries cannot be assembled, affect the electrochemical performance of solid-state lithium batteries, and lithium ions cannot pass smoothly, etc. problem, to achieve the effect of solving poor interface contact, reducing transmission impedance, and improving interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

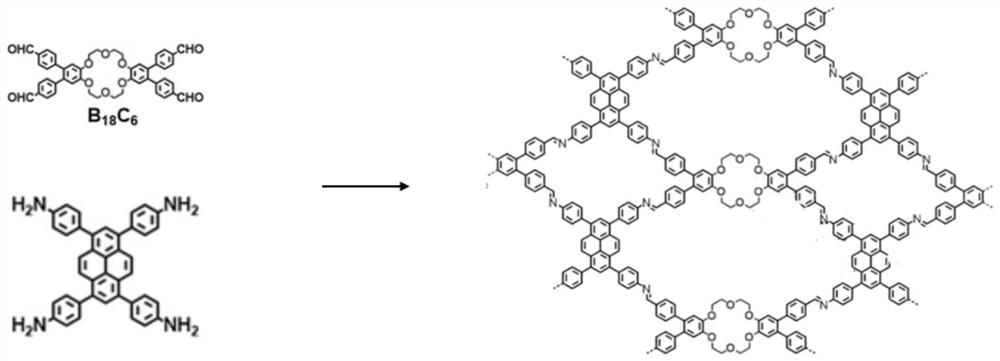

[0083] Preparation of crown ethers COFs-1:

[0084] S1: In a glove box filled with argon, the LLZTO (Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 ) the surface of the electrolyte, and then use anhydrous tetrahydrofuran solvent to wash off the residual impurities on the surface of the electrolyte;

[0085] S2: Place the clean LLZTO electrolyte treated in step S1 in a reaction flask containing 0.024 mmol 1,3,6,8-tetrakis-(p-aminophenyl)-pyrene and 10 mL o-dichlorobenzene solution, and Stir at 50°C for 1 hour;

[0086] S3: Add 0.024mmol of B to the above solution 18 C 6 And 0.1mL 6M acetic acid solution, and continue to stir and react at 50°C for 24h;

[0087] S4: The unreacted residue was washed away with anhydrous tetrahydrofuran, and heated at 50° C. for 1 h to remove the residual solvent. ;

[0088] S5: Add a crystallization transition solvent consisting of 13.5 mL of o-dichlorobenzene and 1.5 mL of n-butanol to the COF@LLZTO material prepared in step S4, and simultaneously ad...

Embodiment 2

[0093] Preparation of crown ethers COFs-2:

[0094] S1: In a glove box filled with argon, the LLZTO (Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 ) the surface of the electrolyte, and then use anhydrous tetrahydrofuran solvent to wash away possible residual impurities on the surface of the electrolyte;

[0095] S2: Place the clean LLZTO electrolyte treated in step S1 in a reaction flask containing 0.024 mmol 1,3,6,8-tetrakis-(p-aminophenyl)-pyrene and 10 mL o-dichlorobenzene solution, and Stir at ℃ for 1 h;

[0096] S3: Add 0.024mmol of B to the above solution 24 C 8 And 0.1mL 6M acetic acid solution, and continue to stir and react at 50°C for 24h;

[0097] S4: wash off the unreacted residue with anhydrous tetrahydrofuran, and heat at 50° C. for 1 h to remove the residual solvent;

[0098] S5: Add a crystallization transition solvent consisting of 13.5 mL of o-dichlorobenzene and 1.5 mL of n-butanol to the COF@LLZTO material prepared in step S4, and simultaneously add 1.5 mL of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com