Ointment for removing slough and promoting tissue regeneration, preparation method and application thereof

A technology of removing putrefaction and promoting granulation and ointment, which is applied in the field of medicine, can solve the problems of slow granulation formation and growth, poor cell metabolism, and unsatisfactory clinical curative effect, so as to promote the proliferation of granulation tissue, cell regeneration, collagen synthesis and The effect of capillary neovascularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

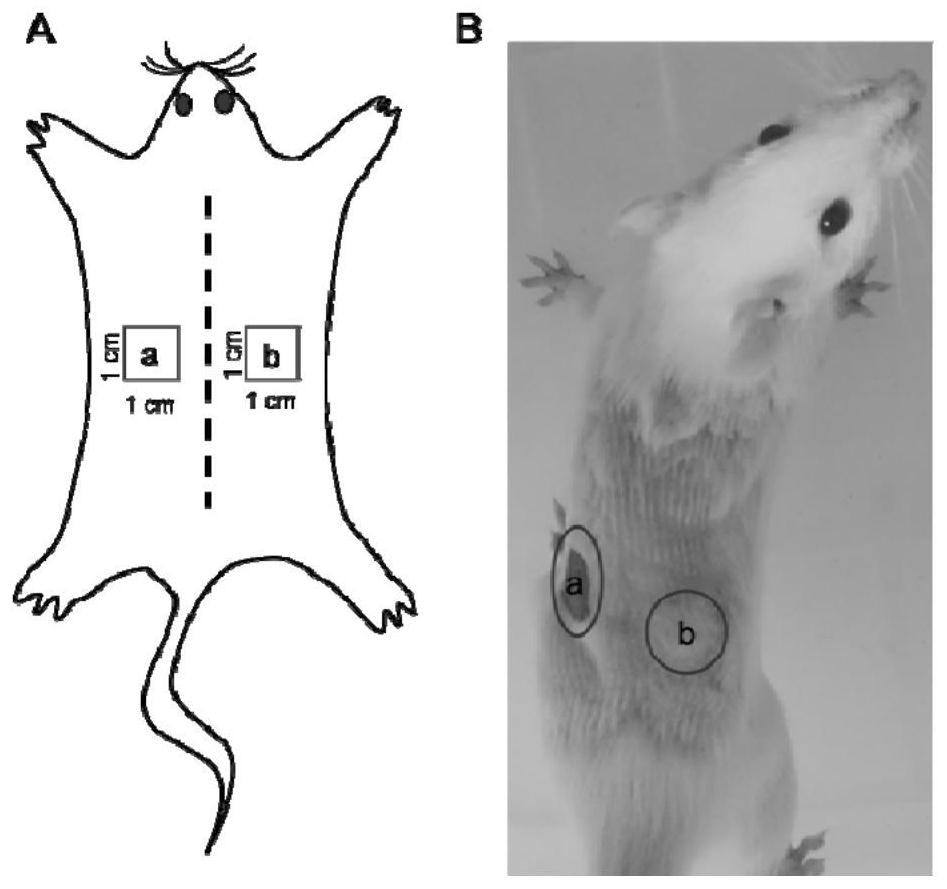

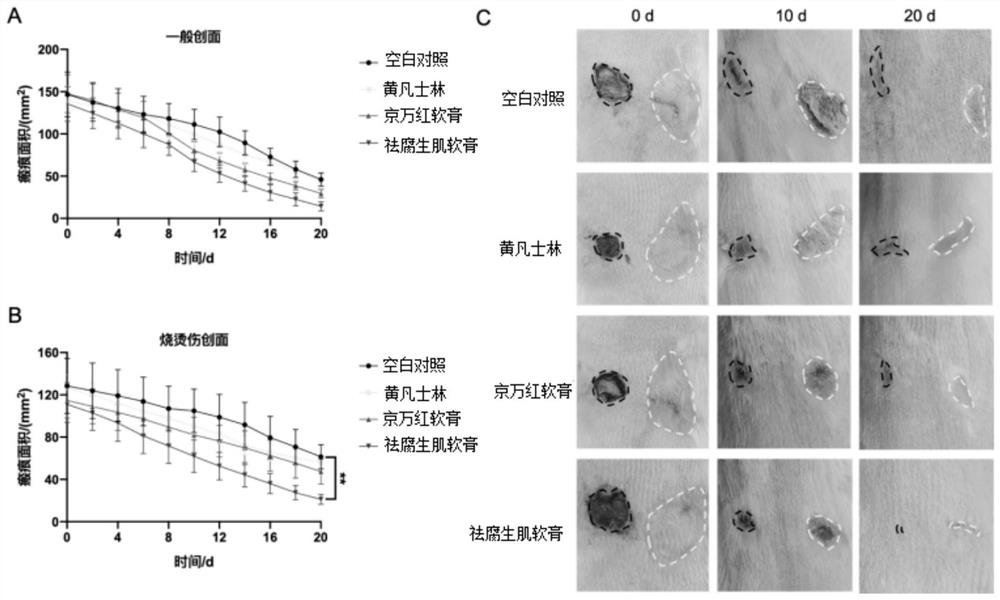

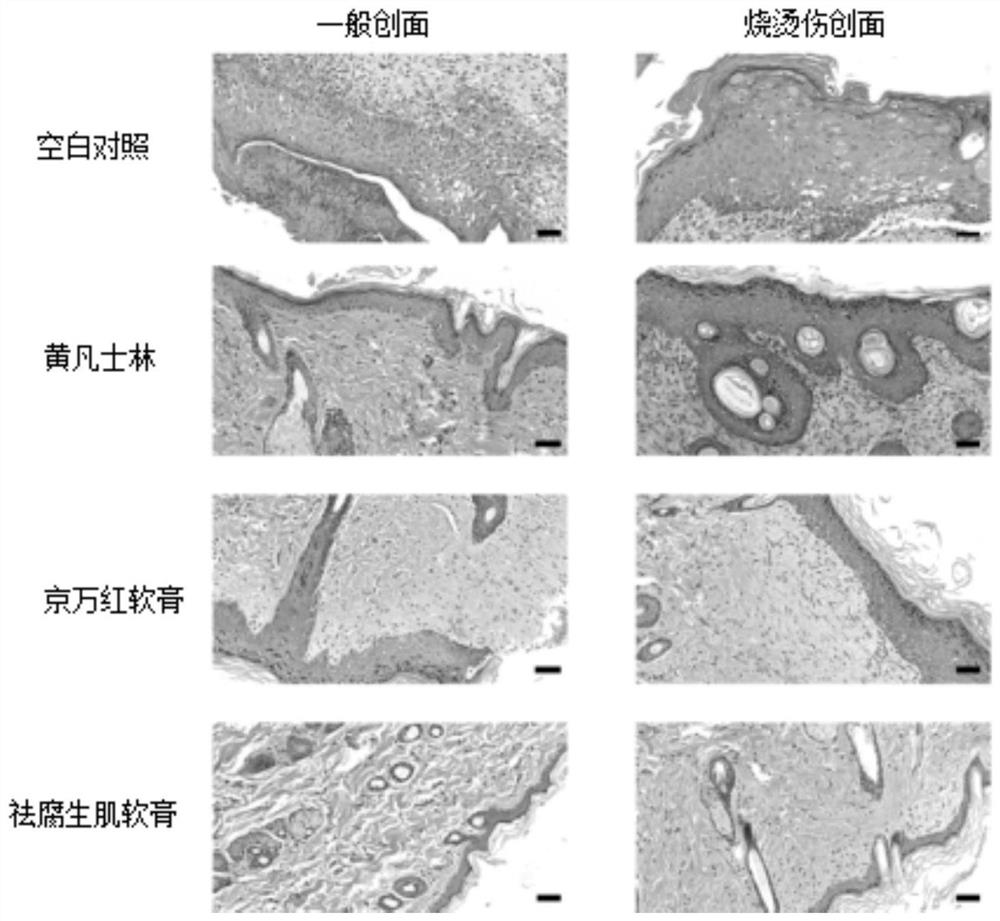

Image

Examples

preparation example Construction

[0039] The preparation method of described putrefaction-promoting granulation ointment, comprises the steps:

[0040] Preparation of traditional Chinese medicine powder: respectively crush calamine, gypsum (calcined), mother-of-pearl powder (calcined), cold water stone powder (calcined), borneol, and centella asiatica into fine powders according to the above weight parts, pass through a 80-100 mesh sieve, and mix evenly, to obtain mixed traditional Chinese medicine powder; crush the borax in the above weight portion into fine powder, and pass through a 80-100 mesh sieve to obtain borax powder;

[0041] Prepare the base: melt the raw materials of the ointment base according to the above weight parts, stir, and stir at a speed of 100-500 r / min, and obtain the base after mixing;

[0042] Preparation of ointment: add the mixed traditional Chinese medicine powder into the melted matrix, stir at a speed of 100-500r / min for 4-6h, until the temperature drops to about 40°C, add the bor...

Embodiment 1

[0047] This embodiment provides an ointment for removing putrefaction and promoting granulation, which includes by weight: 30 parts of calamine, 100 parts of gypsum (calcined), 20 parts of mother-of-pearl powder (calcined), cold water stone powder (calcined) 20 parts, 100 parts of borax, 5 parts of borneol, 20 parts of centella asiatica, 105 parts of liquid paraffin and 600 parts of yellow petrolatum.

[0048] The preparation method of described putrefaction-promoting granulation ointment, comprises the steps:

[0049] Preparation of traditional Chinese medicine powder: crush calamine, gypsum (calcined), mother-of-pearl powder (calcined), cold water stone powder (calcined), borneol, and centella asiatica in the above parts by weight into fine powder, pass through a 80-100 mesh sieve, and mix well , to obtain mixed traditional Chinese medicine powder; crush the borax in the above weight portion into fine powder, and pass through a 80-100 mesh sieve to obtain borax powder;

[0...

Embodiment 2

[0054] This embodiment provides an ointment for removing putrefaction and promoting granulation, which includes by weight: 10 parts of calamine, 70 parts of gypsum (calcined), 10 parts of mother-of-pearl powder (calcined), cold water stone powder (calcined) 10 parts, 70 parts of borax, 1 part of borneol, 10 parts of centella asiatica, 300 parts of liquid paraffin and 519 parts of yellow petrolatum.

[0055] The preparation method of described putrefaction-promoting granulation ointment, comprises the steps:

[0056] Preparation of traditional Chinese medicine powder: crush calamine, gypsum (calcined), mother-of-pearl powder (calcined), cold water stone powder (calcined), borneol, and centella asiatica in the above parts by weight into fine powder, pass through a 80-100 mesh sieve, and mix well , to obtain mixed traditional Chinese medicine powder; crush the borax in the above weight portion into fine powder, and pass through a 80-100 mesh sieve to obtain borax powder;

[0057...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com