Multifunctional hydrogel for immobilizing SRB through microbiological method and preparation method thereof

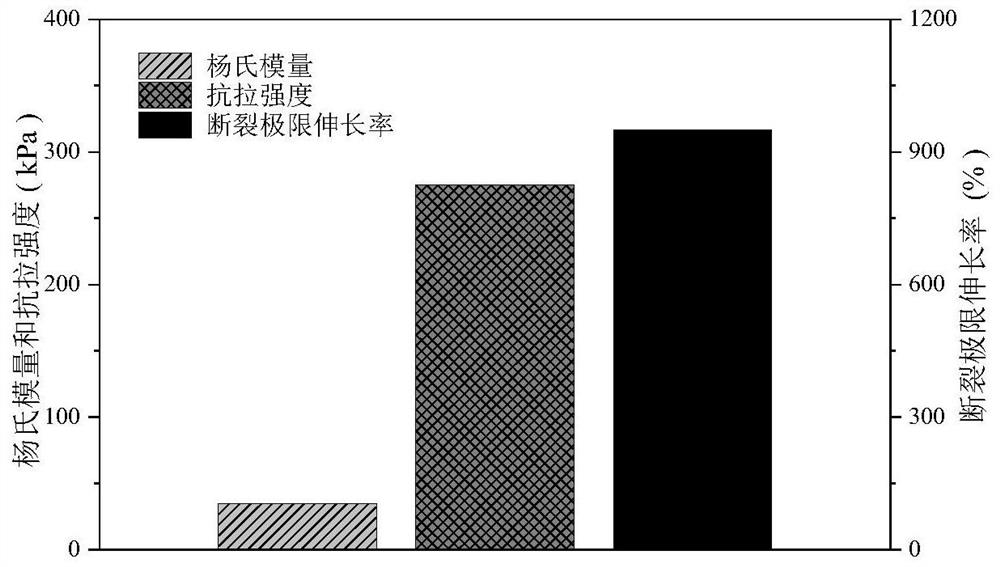

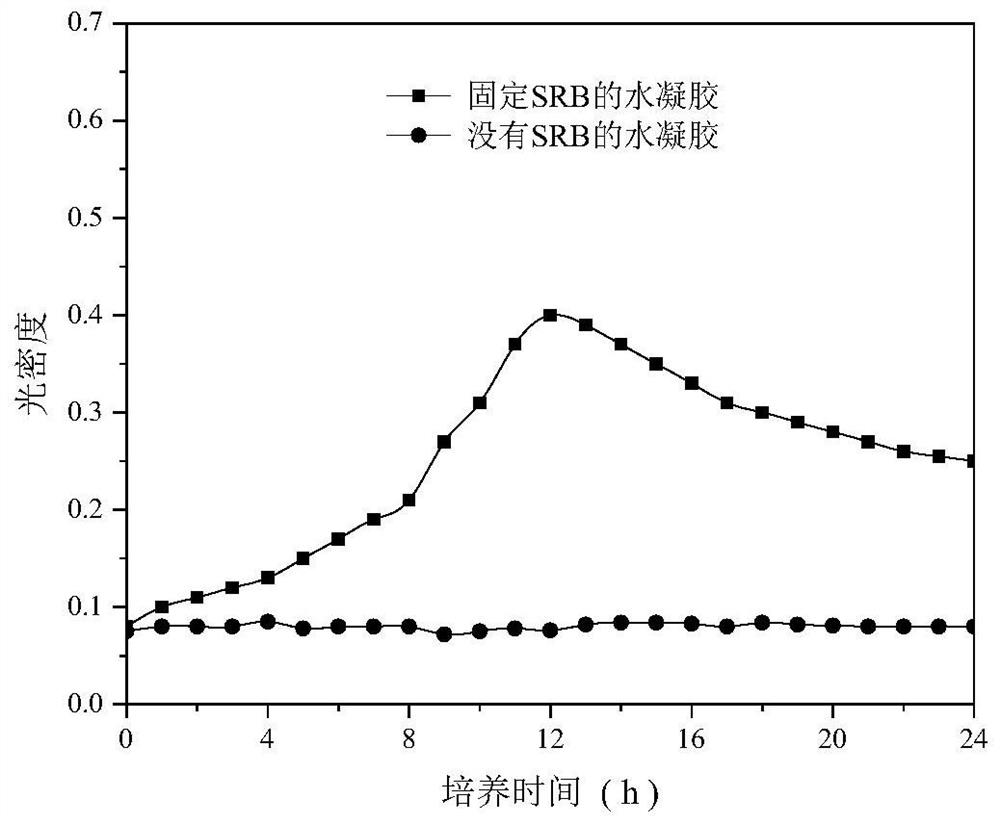

A microbial method and hydrogel technology, applied in gel preparation, biological water/sewage treatment, chemical instruments and methods, etc., to achieve the effects of improving treatment efficiency, improving heavy metal content, and excellent ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

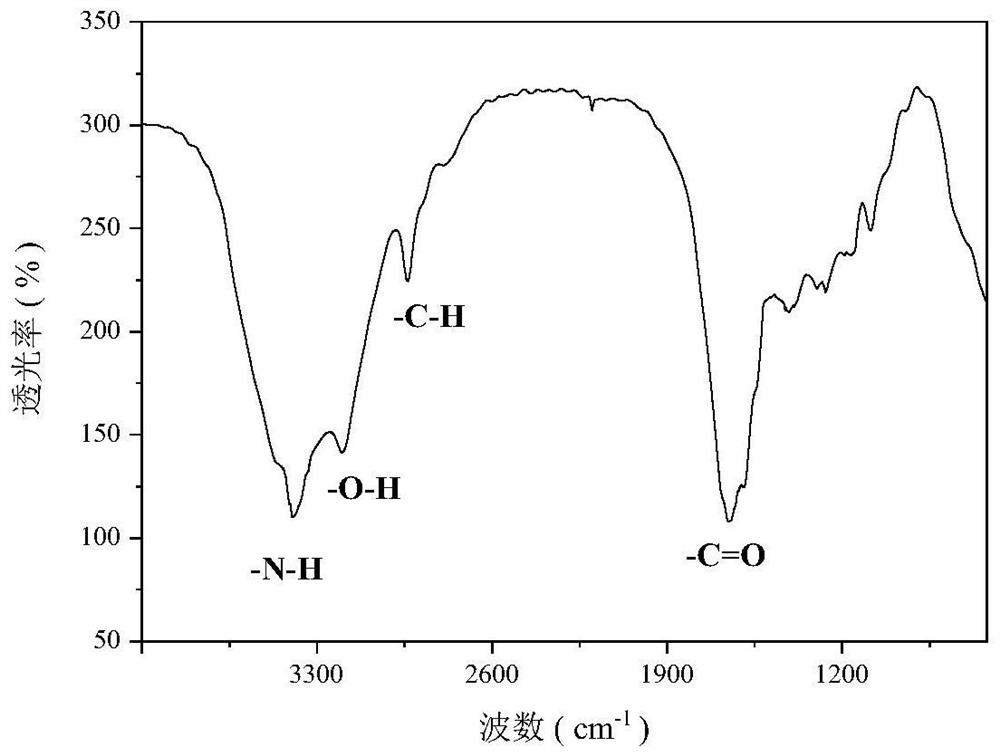

[0030] (1) Synthesis of self-healing, high mechanical strength acryloyl-containing hydrogels

[0031]Dissolve 3.2 g of glycinamide hydrochloride in 50 mL of N,N-dimethylformamide, and place in an ice bath to cool. Subsequently, 3.5 mL of acryloyl chloride was added dropwise to the solution, and the solution was stirred at room temperature for 4 hours. After stirring, add HCl solution for acidification, the pH after acidification is 2.0, and then wash with ether for 3-5 times. The pH was then adjusted to neutral by adding NaOH solution, and the solution was lyophilized overnight. The freeze-dried initial product was extracted with a methanol / ethanol mixed solution with a volume ratio of 1:2, and the extracted organic layer was concentrated in vacuo and cooled for recrystallization to obtain N-acryloylglycinamide.

[0032] Dissolve 5.6 g of L-alanine in 50 mL of N,N-dimethylformamide containing 1.5 mL of ethylenediamine, and place in an ice bath to cool. Afterwards, 3.1 mL of...

Embodiment 2

[0037] (1) Synthesis of self-healing, high mechanical strength acryloyl-containing hydrogels

[0038] Dissolve 4.3 g of glycinamide hydrochloride in 80 mL of N,N-dimethylformamide, and place in an ice bath to cool. Subsequently, 5.1 mL of acryloyl chloride was added dropwise to the solution, and the solution was stirred at room temperature for 3 hours. After stirring, add HCl solution for acidification, the pH after acidification is 3.0, and then wash with ether for 3-5 times. The pH was then adjusted to neutral by adding NaOH solution, and the solution was lyophilized overnight. The freeze-dried primary product was extracted with a methanol / ethanol mixed solution with a volume ratio of 1:1, and the extracted organic layer was concentrated in vacuo and cooled for recrystallization to obtain N-acryloylglycinamide.

[0039] Dissolve 2.8 g of L-alanine in 80 mL of N,N-dimethylformamide containing 1.0 mL of ethylenediamine, and place in an ice bath to cool. Afterwards, 4.2 mL o...

Embodiment 3

[0044] (1) Synthesis of self-healing, high mechanical strength acryloyl-containing hydrogels

[0045] Dissolve 5.8 g of glycinamide hydrochloride in 80 mL of N,N-dimethylformamide, and place in an ice bath to cool. Subsequently, 6.2 mL of acryloyl chloride was added dropwise to the solution, and the solution was stirred at room temperature for 6 hours. After stirring, add HCl solution for acidification, the pH after acidification is 4.5, and then wash with ether for 3-5 times. The pH was then adjusted to neutral by adding NaOH solution, and the solution was lyophilized overnight. The freeze-dried primary product was extracted with a methanol / ethanol mixed solution with a volume ratio of 1:4, and the extracted organic layer was concentrated in vacuo and cooled for recrystallization to obtain N-acryloylglycinamide.

[0046] Dissolve 8.2 g of L-alanine in 80 mL of N,N-dimethylformamide containing 1.6 mL of ethylenediamine, and place in an ice bath to cool. Afterwards, 7.3 mL o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com