Activated carbon for antibiotic adsorption treatment as well as preparation method and application thereof

An adsorption treatment and activated carbon technology, applied in the field of porous materials, can solve the problems of inability to meet the needs of antibiotic pollution treatment, poor antibiotic adsorption effect, and high product cost performance, and achieve effective recovery and enrichment, low treatment cost, and high product cost-effective effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

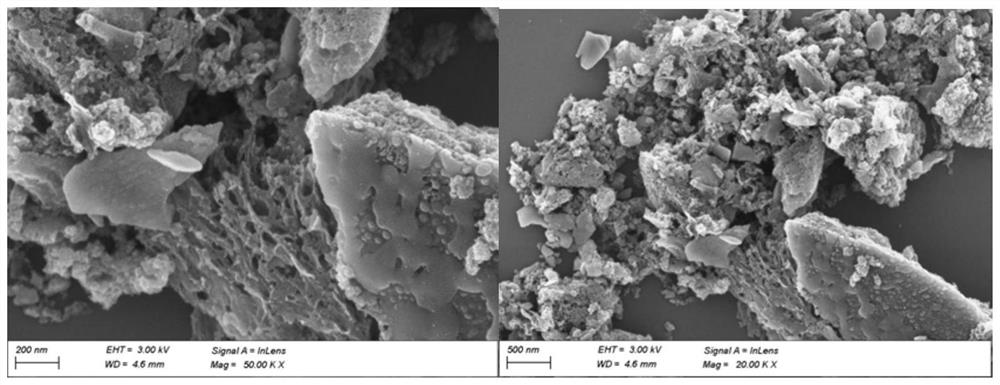

[0032] A method for preparing activated carbon for antibiotic adsorption treatment, comprising the following steps: crush rubber seed shells, pass through a 100-mesh sieve, and dry at 70°C; weigh 2g of rubber seed shell powder and add water to 200mL. Immerse for 2 hours, evaporate the water to dryness at 70°C, and then dry at 135°C for 2 hours; carbonize the dried material in a tube furnace for 1 hour under the protection of nitrogen, the carbonization temperature is 800°C, the heating rate is 5°C / min, nitrogen The flow rate is 100 mL / min. The obtained product was washed twice with hydrochloric acid, and then washed with deionized water until the washing liquid was neutral. Finally, put the washed product into a drying oven and dry it at 70°C for 2 hours to obtain the modified activated carbon.

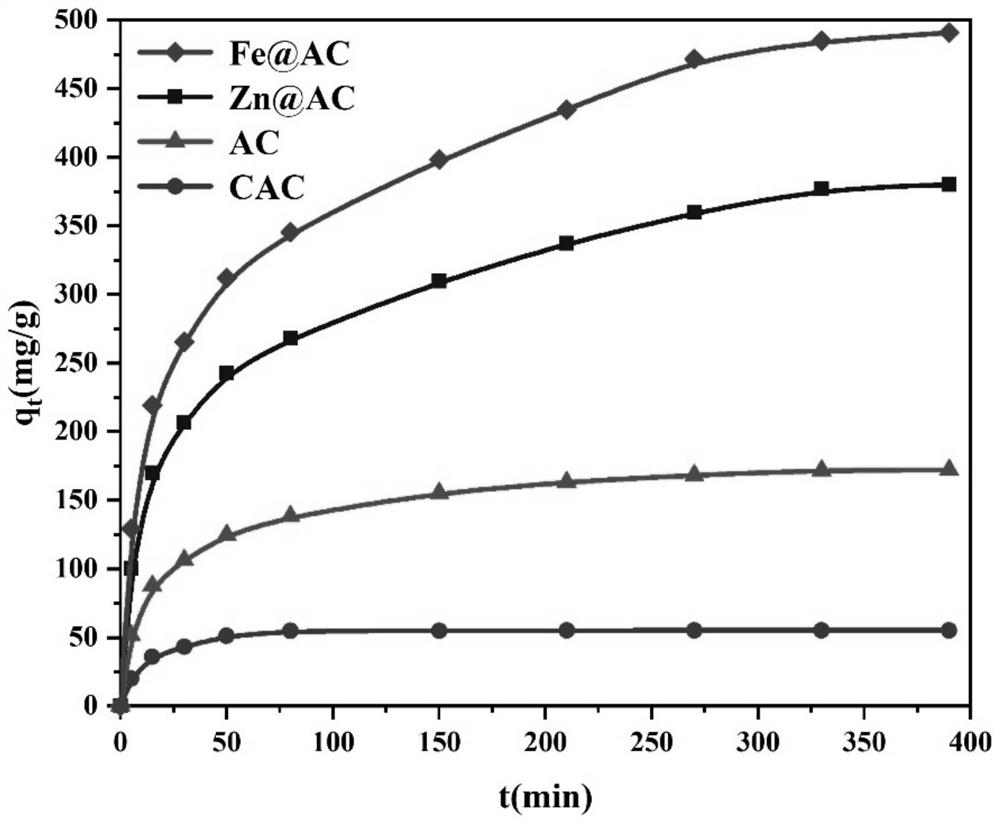

[0033] Weigh 5 mg of the above modified activated carbon and place it in 100 mL of antibiotic solution with a concentration of 80 mg / L. After 22 hours, the adsorption capacity of tet...

Embodiment 2

[0035] A preparation method of activated carbon for antibiotic adsorption treatment, which includes the following steps: crush rubber seed shells and pass through a 100-mesh sieve, and dry at 70°C; weigh 2g of rubber seed shell powder, and then weigh 4g of FeCl 3 ·6H 2 O Mix the two, add water to 200mL, soak for 2h, evaporate the water to dryness at 70°C, and then dry at 135°C for 2h; carbonize the dried product in a tube furnace for 1h under the protection of nitrogen, and the carbonization temperature is 700°C. The heating rate was 5 °C / min, and the nitrogen flow rate was 100 mL / min. The prepared product was washed twice with hydrochloric acid, and then washed with deionized water until the washing solution was neutral; finally, the washed product was dried in a drying oven at 70°C for 2 hours to obtain modified activated carbon.

[0036] Weigh 5 mg of the above-mentioned modified activated carbon and place it in 100 mL of antibiotic solution with a concentration of 80 mg / L...

Embodiment 3

[0038] A preparation method of activated carbon for antibiotic adsorption treatment, which includes the following steps: crush rubber seed shells through a 60-mesh sieve, and dry at 55°C; weigh 2g of rubber seed shell powder, and then weigh 6g of FeCl 3 ·6H 2O Mix the two, add water to 200mL and impregnate for 2h, evaporate the water to dryness at 70°C, and then dry at 135°C for 2h; carbonize the dried product in a tube furnace for 1h under the protection of nitrogen, and the carbonization temperature is 650°C. The heating rate is 6°C / min, and the nitrogen flow rate is 100mL / min; the prepared product is washed twice with hydrochloric acid, and then washed with deionized water until the washing solution is neutral; finally, the washed product is placed in a drying oven Dry at 70°C for 2 hours to obtain modified activated carbon.

[0039] Weigh 5 mg of the above-mentioned modified activated carbon and place it in 100 mL of antibiotic solution with a concentration of 80 mg / L. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com