Combustible cartridge case/box slurry formula and preparation method of combustible cartridge case/box

A cartridge and formula technology, which is applied in the directions of non-explosive filler/gelling agent/thickener, explosives processing equipment, non-explosive/non-thermal agent components, etc., can solve the problem of poor heat resistance, high hygroscopicity and poor flexibility and other problems, to achieve the effect of improving heat resistance time and energy, reducing moisture absorption rate and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The formula of the present embodiment is as follows: 100 parts of epoxy acrylic resin, 3 parts of TPO photoinitiator, 40 parts of 2-(2-ethoxyethoxy) ethyl acrylate reactive diluent, RDX crystal (average particle size 30 μm) 100 copies. The preparation steps are as follows:

[0030] (1) Mix all the components with a stirrer in the dark for 1 hour at a speed of 200 rpm;

[0031] (2) Pour the uniformly mixed material into the trough of the SLA 3D printer (Form 3SLA printer of model formlabs), and the laser wavelength of the printer is 405nm;

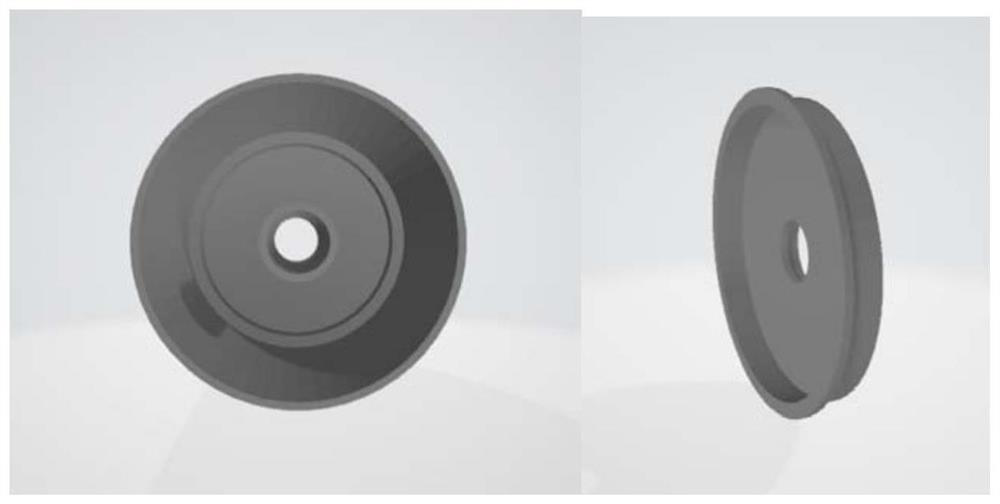

[0032] (3) Select the model of the combustible cartridge to print (generate the model in the cura software), such as figure 1 As shown, use SLA3D printer to print;

[0033] (4) Remove the printed cartridge from the forming platform and clean it with ethanol or glycerin;

[0034] (5) Place the cartridge under a UV curing lamp for 3 hours of light.

Embodiment 2

[0036] Different from Example 1, the formula of this embodiment is as follows: 60 parts of epoxy acrylic resin, 40 parts of polyurethane acrylic resin, 3 parts of TPO-L photoinitiator, 50 parts of trimethylolpropane triacrylate reactive diluent 152 parts of RDX crystals (average particle size 50 μm).

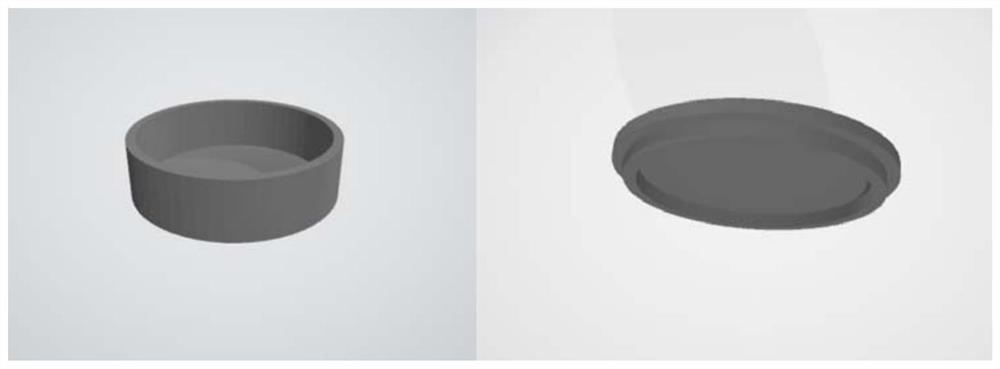

[0037] The difference between the preparation process and Example 1 is that the model is as figure 2 Shown is a combustible cartridge for a solid propellant motor igniter.

Embodiment 3

[0039] Different from Example 1, the mass ratio of this example is as follows: 50 parts of epoxy acrylic resin, 50 parts of epoxy acrylic resin, 4 parts of TPO-L photoinitiator, 2-(2-ethoxyethoxy ) 40 parts of ethyl acrylate reactive diluent, 20 parts of trimethylolpropane triacrylate reactive diluent, 246 parts of RDX crystal (average particle size 70 μm).

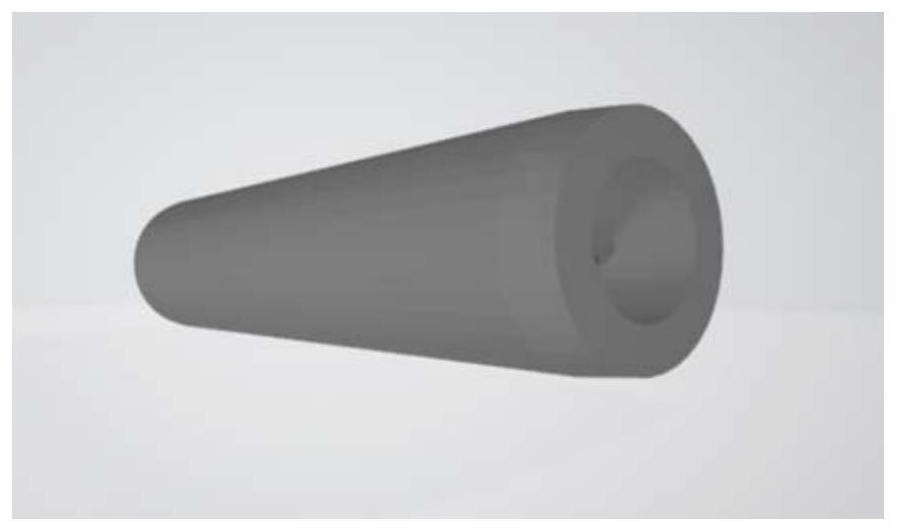

[0040] The difference between the preparation process and Example 1 is that the model is as image 3 Shown is a combustible cartridge for countersunk ammunition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com