PBAT resin composition and preparation method and application thereof

A resin composition and resin technology, applied in the field of polymer materials, can solve problems such as redness or purpleness, yellowish product color, unstable appearance color, etc., and achieve good mechanical properties and mechanical properties, excellent mechanical strength and toughness , the effect of improving the appearance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

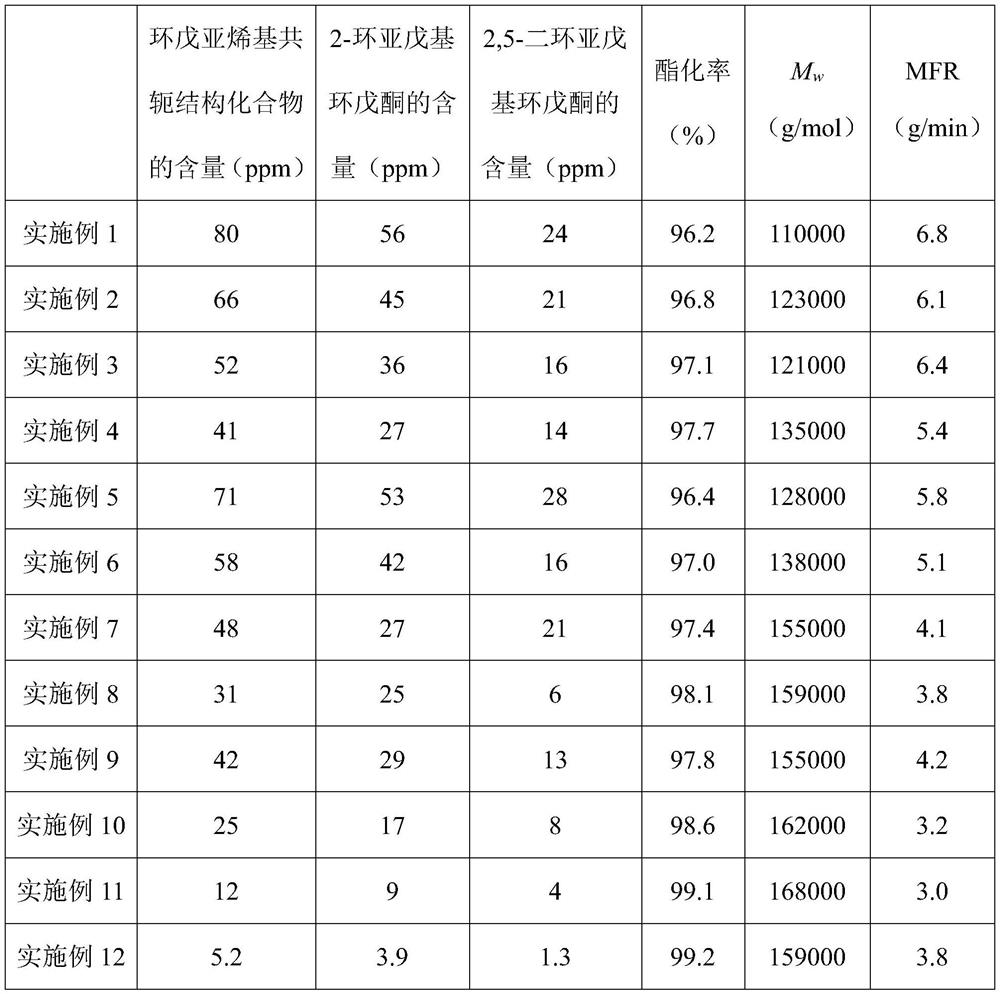

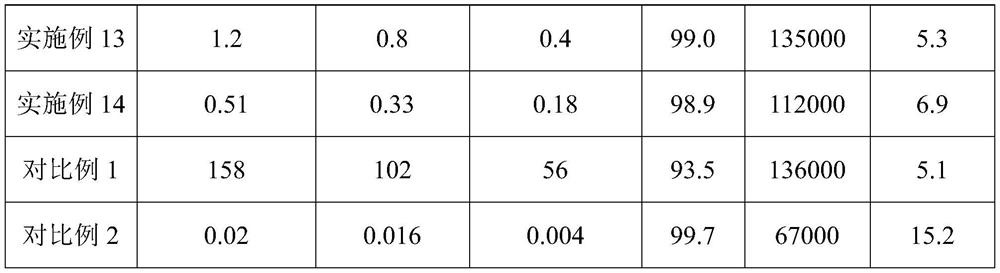

Embodiment 1

[0149] A kind of PBAT resin composition, comprises PBAT resin and cyclopentylidene conjugated structure compound (2-cyclopentylene cyclopentanone and 2,5-dicyclopentylene cyclopentanone); Preparation method is as follows:

[0150] Weigh 1,000g of terephthalic acid, 1,000g of adipic acid, 1,700g of 1,4-butanediol, and 2.37g of tetra-n-butyl titanate into a 5L reaction kettle, start stirring, replace with nitrogen three times, and maintain normal pressure. Raise the temperature of the reaction system to 220°C, react for 90min, and the esterification rate is 96.2%; Nitrogen is filled into the reactor to return the reactor to normal pressure to obtain a PBAT melt, which is extruded under the protection of nitrogen, cooled to room temperature, and pelletized to obtain the PBAT resin composition.

Embodiment 2

[0152] A kind of PBAT resin composition, comprises PBAT resin and cyclopentylidene conjugated structure compound (2-cyclopentylene cyclopentanone and 2,5-dicyclopentylene cyclopentanone); Preparation method is as follows:

[0153] Weigh 990g of terephthalic acid, 1100g of adipic acid, 1750g of 1,4-butanediol, and 2.73g of tetra-n-butyl titanate into a 5L reactor, start stirring, replace with nitrogen three times, and maintain normal pressure. Raise the temperature of the reaction system to 215°C, react for 120min, and the esterification rate is 96.8%; Nitrogen is filled into the reactor to return the reactor to normal pressure to obtain a PBAT melt, which is extruded under the protection of nitrogen, cooled to room temperature, and pelletized to obtain the PBAT resin composition.

Embodiment 3

[0155] A kind of PBAT resin composition, comprises PBAT resin and cyclopentylidene conjugated structure compound (2-cyclopentylene cyclopentanone and 2,5-dicyclopentylene cyclopentanone); Preparation method is as follows:

[0156] Weigh 980g of terephthalic acid, 1250g of adipic acid, 1680g of 1,4-butanediol, and 2.68g of tetra-n-butyl titanate and add them into a 5L reaction kettle, start stirring, nitrogen replacement 3 times, and maintain normal pressure. Raise the temperature of the reaction system to 210°C, react for 130min, and the esterification rate is 97.1%; Nitrogen is filled into the reactor to return the reactor to normal pressure to obtain a PBAT melt, which is extruded under the protection of nitrogen, cooled to room temperature, and pelletized to obtain the PBAT resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com