Bacillus licheniformis extracellular polymeric substance organic selenium product as well as preparation method and application thereof

A technology of Bacillus licheniformis and extracellular polymers, which is applied in the field of preparation of organic trace elements, can solve the problems of limitations, limitations of production capacity and efficiency tolerance, and biological toxicity, and achieve low production costs and inhibition of intestinal pathogenicity. Effects of pathogenic bacteria and anti-oxidant intestinal pathogenic bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Bacillus licheniformis SPW-1 preserved at -80°C was inoculated in LB agar solid medium for activation. Bacillus licheniformis was screened independently in the early stage and preserved in the China Center for Type Culture Collection, preservation number: CCTCC M 2020298, cultured at 37°C 16h, and then use seed culture to obtain seed liquid based on 37°C and 200rpm cultivation for 20h, the obtained seed liquid is inoculated into the fermentation medium according to the volume ratio of 4%, and cultivated at 37°C and 200rpm for 56h to obtain a fermented liquid, the obtained fermented liquid is sterilized, Alcohol precipitation, freeze-drying to obtain the extracellular polymer of Bacillus licheniformis.

[0054] Wherein, the LB agar solid medium is composed of raw materials of the following concentrations: tryptone 10g / L, yeast powder 5g / L, sodium chloride 10g / L, agar 14g / L.

[0055] Wherein, the seed medium is composed of raw materials with the following concentrations: ...

Embodiment 2

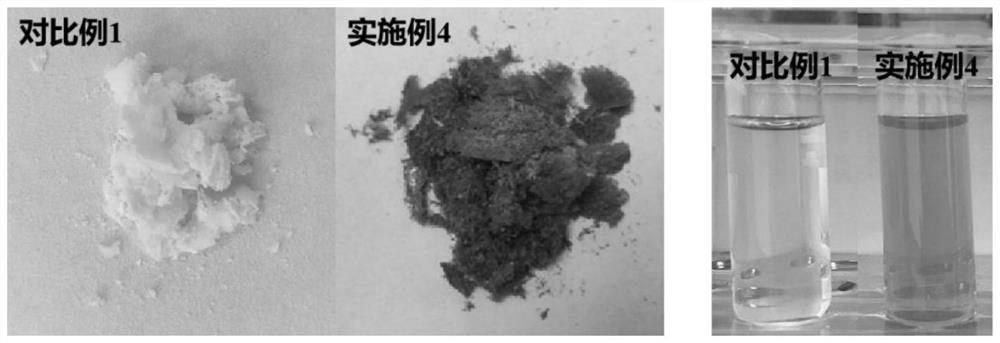

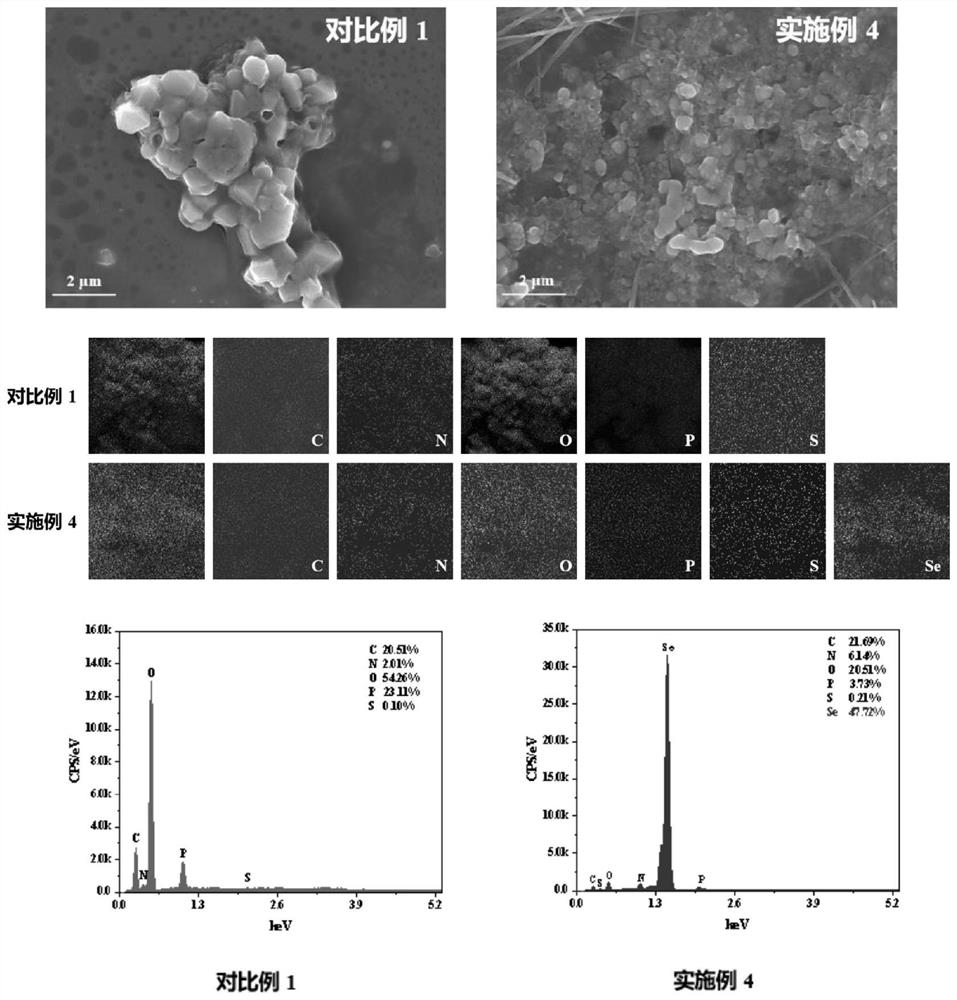

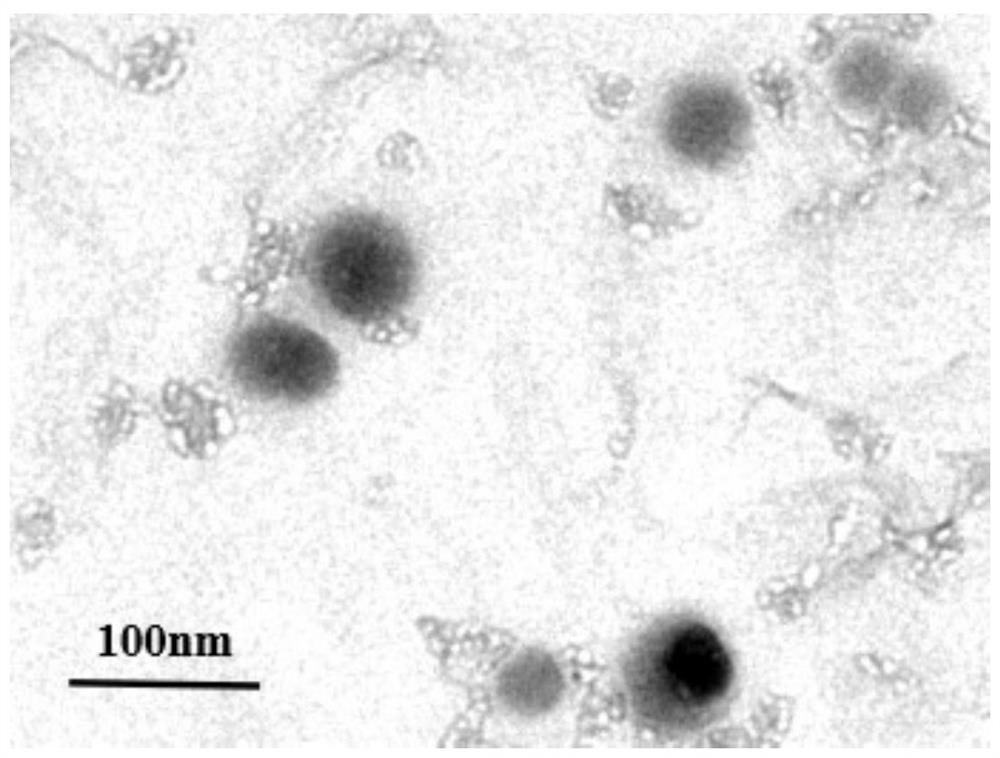

[0059] Weigh 0.1 g of the extracellular polymer of Bacillus licheniformis and dissolve it in water, stir and dissolve in a water bath at 60° C., and the concentration of the extracellular polymer of Bacillus licheniformis is 1.43 g / L. After the solution temperature returns to room temperature, add dropwise a sodium selenite aqueous solution of 50 mM and a 200 mM ascorbic acid aqueous solution (the molar ratio of sodium selenite to ascorbic acid is 1:4), and when the mixed solution becomes blood red, stop Sodium selenite and ascorbic acid were added dropwise, and the reaction was continued for 2h. After the reaction, centrifuge to obtain the supernatant, mix the supernatant with absolute ethanol at a volume ratio of 1:3, let it stand at 4°C for 12 hours, centrifuge to obtain a precipitate, wash with absolute ethanol for 2 to 3 times, and freeze-dry to obtain Bacillus licheniformis extracellular polymer organic selenium, wherein the content of selenium is 96.83mg / g.

Embodiment 3

[0061] Weigh 0.1 g of the extracellular polymer of Bacillus licheniformis and dissolve it in water, stir and dissolve in a water bath at 60° C., and the concentration of the extracellular polymer of Bacillus licheniformis is 1.43 g / L. After the solution temperature returns to room temperature, add dropwise a sodium selenite aqueous solution of 50 mM and a 200 mM ascorbic acid aqueous solution (the molar ratio of sodium selenite to ascorbic acid is 1:4), and when the mixed solution becomes blood red, stop Sodium selenite and ascorbic acid were added dropwise, and the reaction was continued for 2h. After the reaction, centrifuge to obtain the supernatant, mix the supernatant with absolute ethanol at a volume ratio of 1:3, let it stand at 4°C for 12 hours, centrifuge to obtain a precipitate, wash with absolute ethanol for 2 to 3 times, and freeze-dry to obtain Bacillus licheniformis extracellular polymer organic selenium, wherein the content of selenium is 103.39mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com