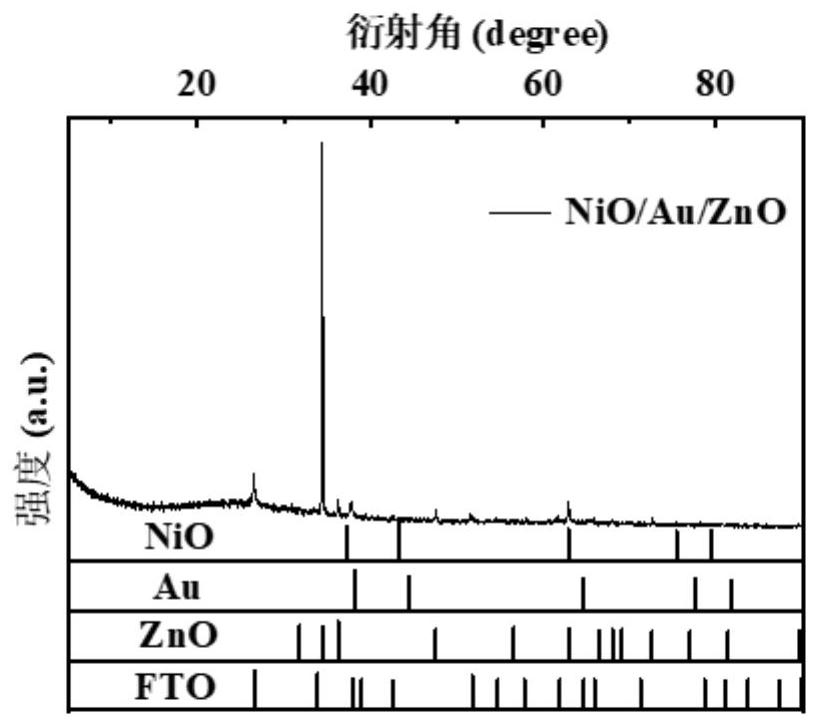

Preparation method and application of nickel oxide-gold-zinc oxide coaxial nano array

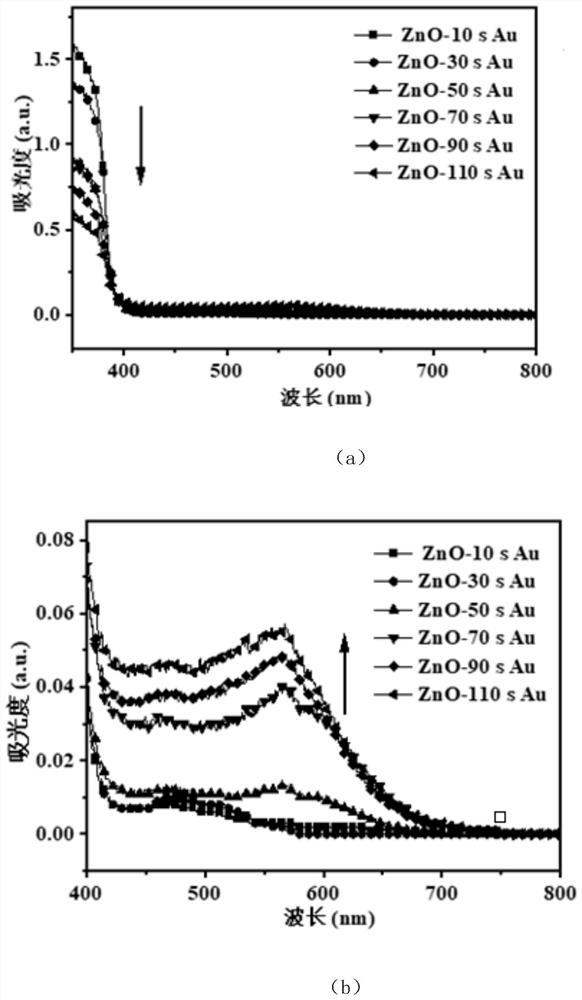

A technology of zinc oxide nanowires and nanowire arrays, applied in nanotechnology, nanotechnology, nanotechnology for sensing, etc., can solve problems such as poor process stability, difficult large-area growth, and complex solution preparation environment, and achieve Excellent photoelectric performance, beneficial to light absorption, and the effect of promoting transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

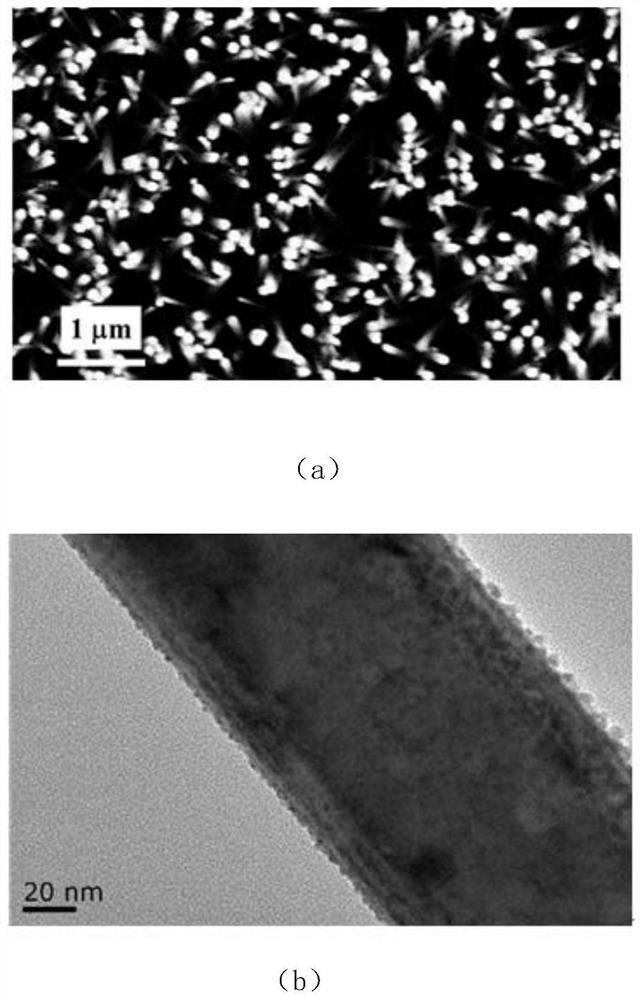

[0029] like Image 6 The, according to the present invention, nickel oxide - gold - Preparation ZnO nanowire arrays coaxially; specific preparation steps are as follows:

[0030] (1), the conductive substrate pretreated into a magnetron sputtering device, evacuated by a mechanical pump and the degree of vacuum molecular pump chamber ≤7.0 × 10 -4 PA, then adjust RF system starter zinc oxide target, the first period of time that the pre-sputter clean the target surface, while allowing the system to stabilize and then into high purity oxygen and high purity argon gas, thereby obtaining an oxide sputtering zinc seed layer substrate;

[0031] (2), an equimolar preparation of zinc acetate [Zn (CH 3 COO) 2 · 2H 2 O] and hexamethylenetetramine [(CH 2 ) 6 N 4 ] Aqueous solution in step (1) in the resulting substrate, zinc acetate and hexamethylenetetramine aqueous solution was added to a hydrothermal reaction vessel, and then placed in an oven at 90-120 deg.] C the reaction 4-10h, with ultr...

Embodiment 1

[0047] (1), the FTO conductive glass was cut into 0.5 × 1.0cm 2 Pieces, which in turn is in ultra pure water, each ultrasonic acetone, ethanol, ultrapure water 10min, then washed with ultrapure water, dried soaked in absolute ethanol for standby;

[0048] (2), the first clean FTO conductive glass with a high temperature adhesive tape 0.5 × 0.5cm 2 Electrode area, placed in a magnetron chamber was then evacuated by a mechanical pump and molecular pump chamber reaches a vacuum degree 5.0 × 10 -4 PA, then adjust RF system starter zinc oxide target, the first period of time that the pre-sputter clean the target surface, while allowing the system to stabilize; when the chamber temperature is stabilized, while bubbling high purity oxygen and 50sccm high purity 5sccm argon, when the operating pressure is of 2 Pa, RF power of 50W, the sputtering time was 40min, to obtain a sputtering zinc oxide seed layer of a thickness of 12nm;

[0049] (3), and 0.219g of zinc acetate dissolved in 100mL ...

Embodiment 2

[0053] (1), the FTO conductive glass was cut into 0.5 × 1.0cm 2 Pieces, which in turn is in ultra pure water, each ultrasonic acetone, ethanol, ultrapure water 10min, then washed with ultrapure water, dried soaked in absolute ethanol for standby;

[0054] (2), the first clean FTO conductive glass with a high temperature adhesive tape 0.5 × 0.5cm 2 Electrode area, placed in a magnetron chamber was then evacuated by a mechanical pump and molecular pump chamber reaches a vacuum degree 6.0 × 10 -4 PA, RF system reconditioning zinc oxide target ignition, the first period of time that the pre-sputter clean the target surface, while allowing the system to stabilize; when the chamber temperature is stabilized, while 10sccm into high purity oxygen and high purity 100sccm argon pressure of 3Pa work, 200W of RF power, sputtering time was 40min, a thickness of the sputtering zinc oxide seed layer of 36nm;

[0055] (3), and 2.190g of zinc acetate dissolved in 100mL ultrapure water with a magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com