Perovskite solar cell and preparation method thereof

A technology of solar cells and perovskites, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of long production process time and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing a perovskite solar cell, comprising the following steps:

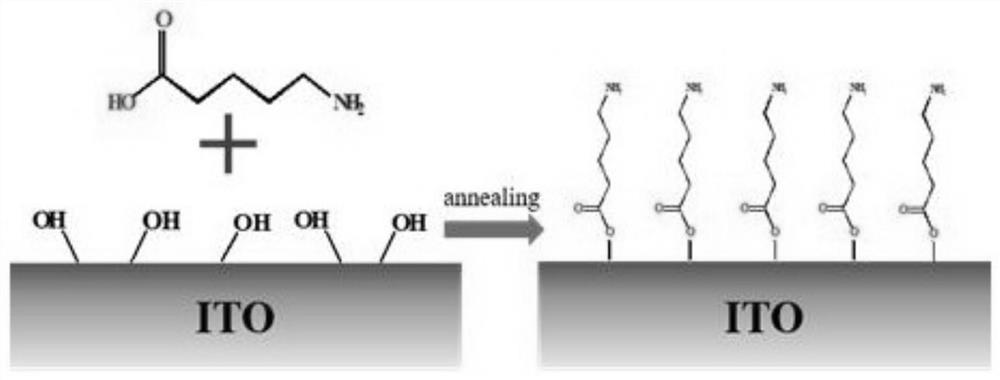

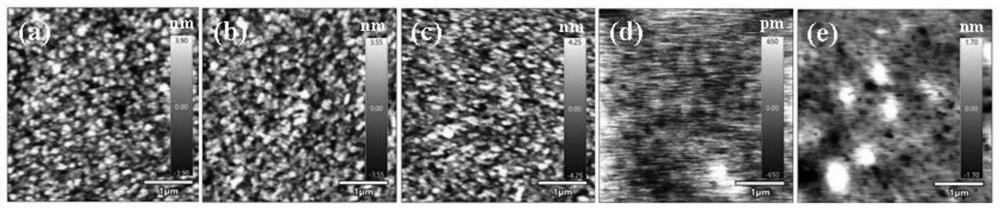

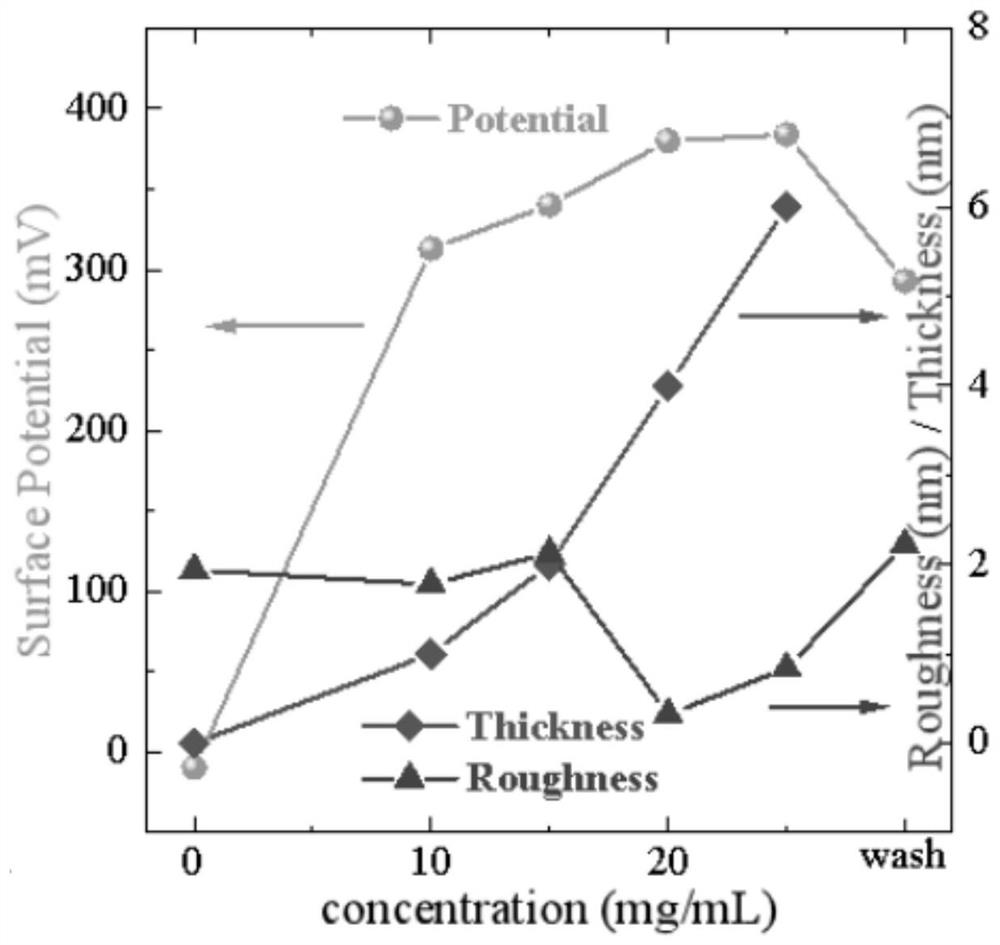

[0033] Step S1: Use deionized water, alcohol, and isopropanol to clean the conductive glass layer (ITO) with a size of 1.5cm*1.5cm, then dry the conductive glass layer, and spin-coat 5-AVA on the surface of the conductive glass layer (5-aminovaleric acid) aqueous solution, spin coating speed is 4000rpm, spin coating time is 30s, and then annealed at 100°C for 10min, on the one hand, it helps to form chemical bonds between 5-AVA and the conductive glass layer, on the other hand Avoid the decomposition of 5-AVA, and finally form a 5-AVA replacement layer on the surface of the conductive glass layer;

[0034] The concentration of 5-AVA in the aqueous solution of 5-AVA in the present embodiment is 10mg / mL;

[0035] Step S2: 1.26mol FAI, 0.14mol CsCl and 1.47mol PbI 2 Dissolve in DMF and DMSO and stir, the volume ratio of DMF and DMSO is 4:1, the stirring temperature ...

Embodiment 2

[0040] The difference between this example and Example 1 is that in step S1, the concentration of 5-AVA in the aqueous solution of 5-AVA is 15 mg / mL.

Embodiment 3

[0042] The difference between this example and Example 1 is that in step S1, the concentration of 5-AVA in the aqueous solution of 5-AVA is 20 mg / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com