Two-dimensional FeNi3/NiFe-MMOs heterostructure material and preparation method and application thereof

A heterostructure and reaction technology, applied in the field of preparation of two-dimensional FeNi3/NiFe-MMOs heterostructure materials, can solve the problems of high price and low reserves of precious metals, and achieve the effect of simple preparation, large reserves and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

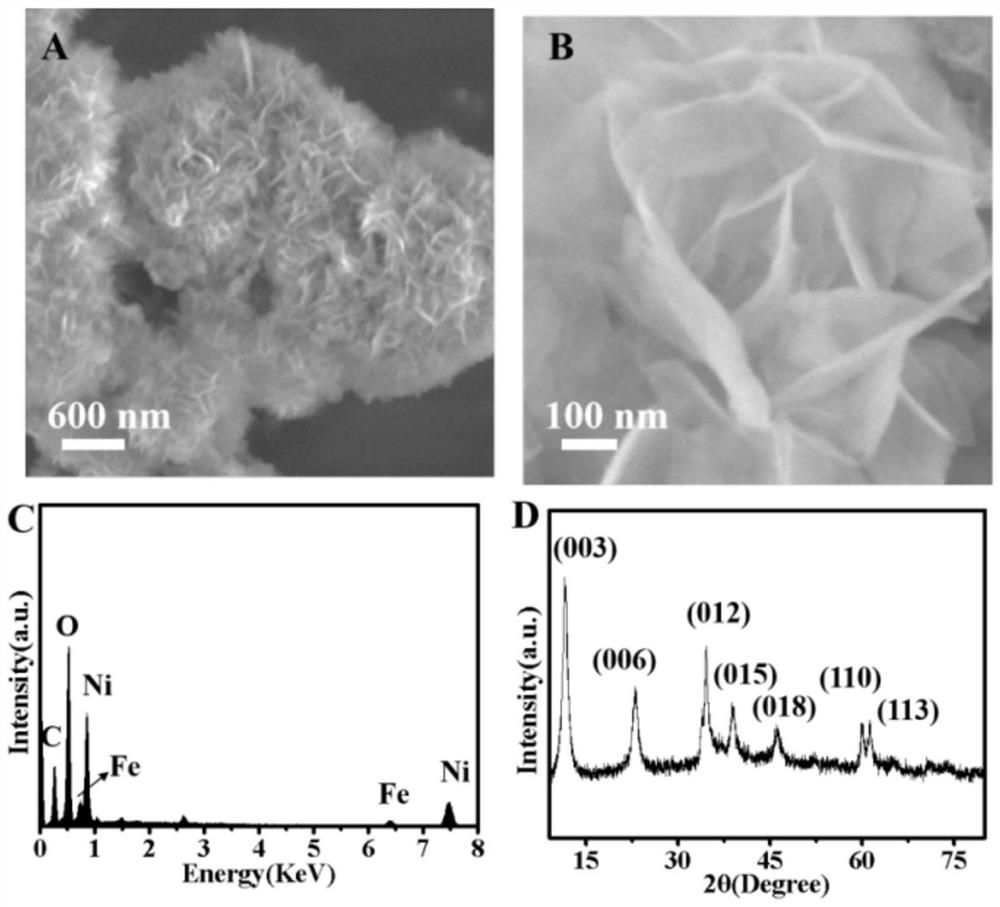

[0034] Step 1: Weigh 0.15g NiCl 2 ·6H 2 O, 0.04g FeCl 3 ·6H 2O, 0.24g urea, 0.006g sodium citrate, dissolved in deionized water, and continued to add deionized water to 40mL, magnetically stirred for 20min. The solution was transferred to a high-pressure reactor, and the high-pressure reactor was sealed and then placed in an electric heating constant temperature blast drying oven. Rise from room temperature to 140°C at a heating rate of 5°C / min, and keep at 140°C for 8 hours. After cooling down to room temperature naturally, the reactor was taken out and the precipitate was extracted by centrifugation, washed alternately with deionized water and absolute ethanol several times, and then stored in a vacuum drying oven at 60°C for 6 hours to dry the sample. Two-dimensional NiFe-LDH was obtained.

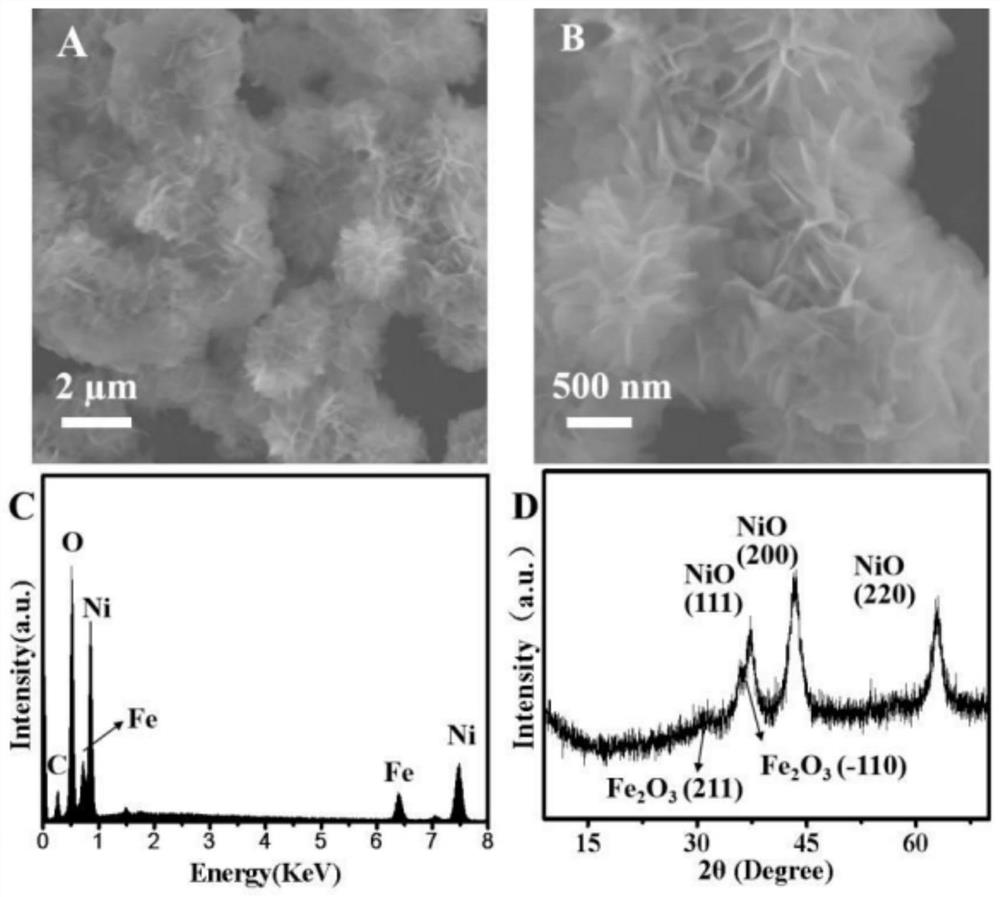

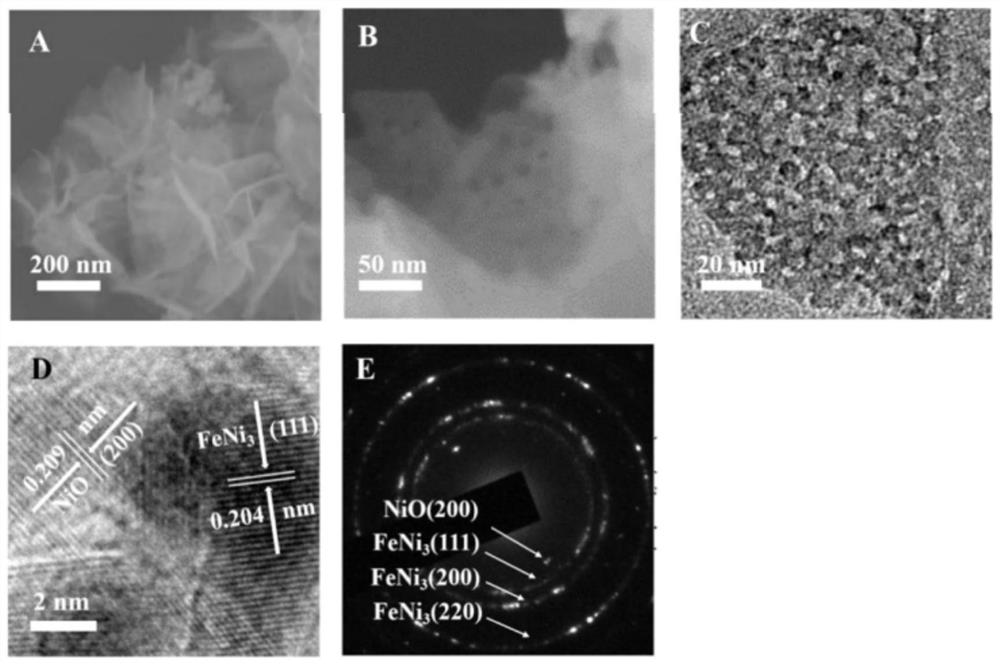

[0035] Step 2: Pour the obtained product into a porcelain boat, lay it flat and transfer it to a tube furnace, raise the temperature from room temperature to 400°C at a rate of 1°C...

Embodiment 2

[0041] Step 1: Weigh 0.15g NiCl 2 ·6H 2 O, 0.04g FeCl 3 ·6H 2 O, 0.30g urea, 0.006g sodium citrate, dissolved in deionized water, and continued to add deionized water to 40mL, magnetically stirred for 20min. The solution was transferred to a high-pressure reactor, and the high-pressure reactor was sealed and then placed in an electric heating constant temperature blast drying oven. Rise from room temperature to 140°C at a heating rate of 5°C / min, and keep at 140°C for 8 hours. After cooling down to room temperature naturally, the reactor was taken out and the precipitate was extracted by centrifugation, washed alternately with deionized water and absolute ethanol several times, and then stored in a vacuum drying oven at 70°C for 12 hours to dry the sample. Two-dimensional NiFe-LDH was obtained.

[0042] Step 2: Pour the obtained product into a porcelain boat, lay it flat and transfer it to a tube furnace, raise the temperature from room temperature to 400°C at a rate of 1...

Embodiment 3

[0045] Step 1: Weigh 0.15g NiCl 2 ·6H 2 O, 0.04g FeCl 3 ·6H 2 O, 0.24g urea, 0.006g sodium citrate, dissolved in deionized water, and continued to add deionized water to 40mL, magnetically stirred for 20min. The solution was transferred to a high-pressure reactor, and the high-pressure reactor was sealed and then placed in an electric heating constant temperature blast drying oven. Rise from room temperature to 120°C at a heating rate of 5°C / min, and keep at 120°C for 10 hours. After cooling down to room temperature naturally, the reactor was taken out and the precipitate was extracted by centrifugation, washed alternately with deionized water and absolute ethanol several times, and then stored in a vacuum drying oven at 60°C for 6 hours to dry the sample. Two-dimensional NiFe-LDH was obtained.

[0046] Step 2: Pour the obtained product into a porcelain boat, lay it flat and transfer it to a tube furnace, raise the temperature from room temperature to 400°C at a rate of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com