Method for enhancing bonding strength of cold spraying coating and base material

A technology of combining strength and cold spraying, which is applied in the field of material engineering, can solve the problems that complex shapes of workpieces are not suitable for the range of process parameters, difficulty in greatly improving the bonding strength, and inconsistent plastic deformation at the interface, so as to achieve wide adaptability of the combined shape of components, Improvement of bond strength, effect of bond strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

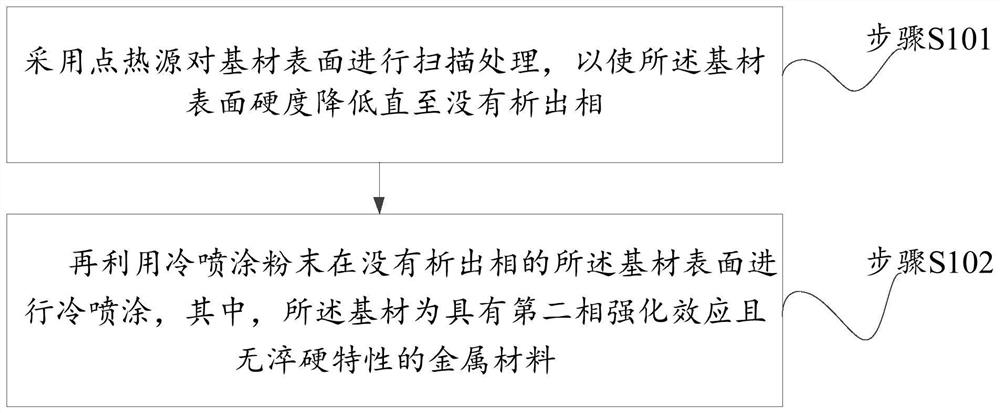

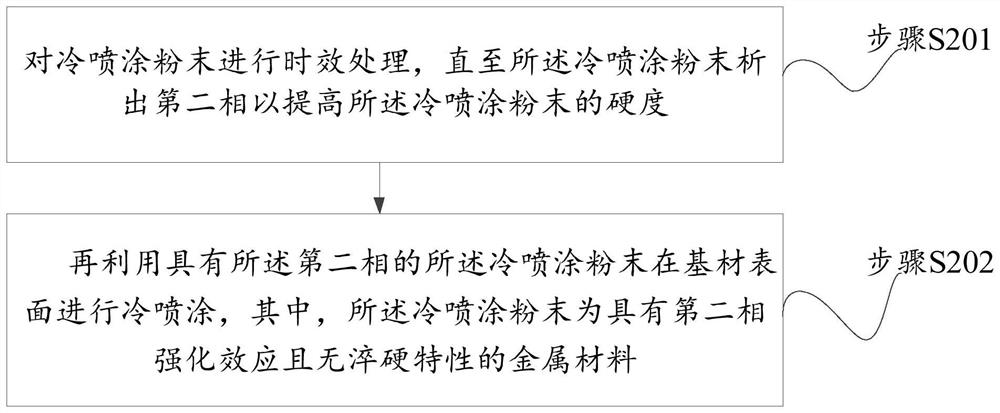

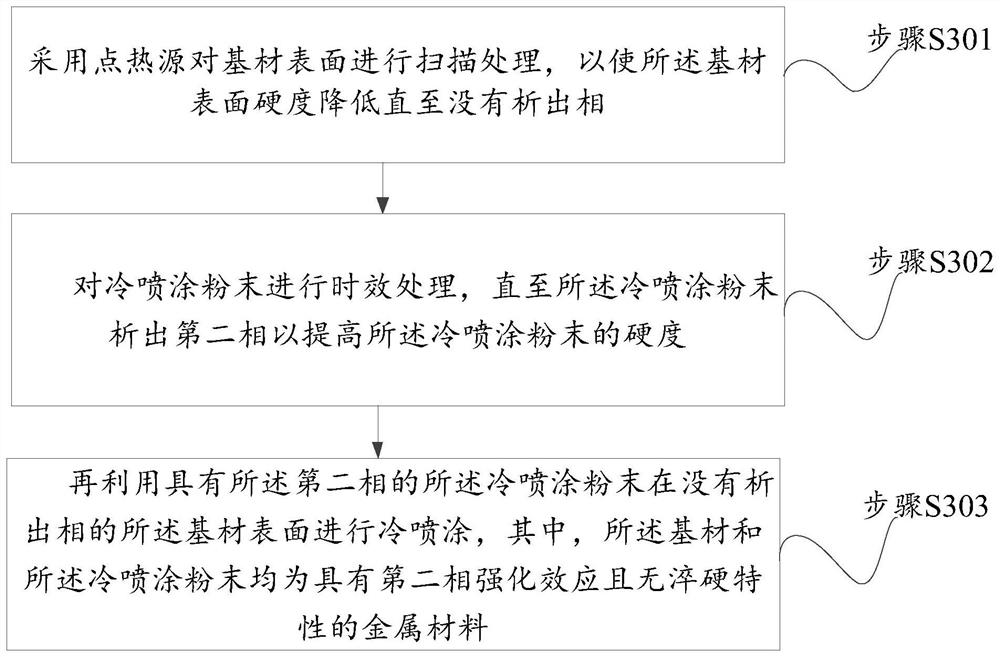

Method used

Image

Examples

Embodiment 1

[0062] The 6061Al alloy powder with a particle size distribution of 10-70m is used as the coating material (i.e. the cold spray powder of the present application), and the AZ31B magnesium alloy is used as the base material, and the aluminum alloy coating is prepared on the surface of the AZ31B magnesium alloy by cold spraying to improve the magnesium alloy. Alloy corrosion resistance. Specifically, firstly, in an argon protective atmosphere, the 6061Al alloy powder was subjected to aging treatment at 170°C under the condition of argon blowing through a rotating electric heating furnace, and the holding time was 4 hours. When the temperature dropped below 50°C, the The powder after aging treatment is taken out from the furnace and vacuum-packed for use. Such as Figure 4a and 4b The comparison shows that after the aging heat treatment, nanoscale precipitates appeared inside the 6061Al alloy powder. The powder was embedded with epoxy glue to prepare metallographic cross-sectio...

Embodiment 2

[0067] Using 7075 hard aluminum alloy powder with a particle size distribution of 15-60m as the raw material of cold spray powder and 7075 hard aluminum alloy as the base material, the repair of cold spray coating in the field of nickel-based superalloy is simulated. Specifically, high-temperature nitrogen was used to perform solution treatment on the surface of the substrate three times, and the surface temperature during the treatment was 510°C. Micro-Vickers hardness tester was used to test the hardness of the substrate surface before and after treatment under the condition of load of 50g and holding time of 10s. The hardness test result showed that the surface hardness of the treated substrate decreased from 185HV to 127HV ,Such as Figure 6a As shown, the thickness of the softened layer is about 150-250m.

[0068] Laser cleaning is used to clean the oxide film on the surface of the substrate before coating preparation, and fine sand (60 mesh) is used for sandblasting tre...

Embodiment 3

[0072] Using Inconel 718 nickel-based superalloy powder with a particle size distribution of 10-50m as the raw material for cold spray powder, and using Inconel 718 nickel-based superalloy as the substrate, simulate the repair of cold spraying in the field of nickel-based superalloy. Specifically, firstly, under an argon protective atmosphere, mix Inconel 718 alloy with alumina powder, and perform aging treatment on the powder at 720°C for 1.5h. When the temperature drops below 50°C, the powder Take it out from the furnace and vacuum seal it for use. Such as Figure 7 As shown, a large number of precipitated phases appeared inside the powder after heat treatment. The powder was inlaid with epoxy glue to prepare a metallographic cross-section sample. The hardness test was carried out with the treated powder, and the hardness of the treated powder was increased from 345HV to 445HV.

[0073] The surface of the superalloy substrate is solid-solution treated with a laser. The las...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Average binding strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com