Three-dimensional structure MXene/SnO2/C negative electrode composite material and preparation method thereof

A three-dimensional structure, composite material technology, applied in the direction of negative electrodes, structural parts, battery electrodes, etc., can solve the problems of pulverization and peeling of active materials, volume expansion of negative battery materials, battery specific capacity attenuation, etc., to delay the pulverization process, The microscopic crystal structure is stable and the effect of preventing rapid decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

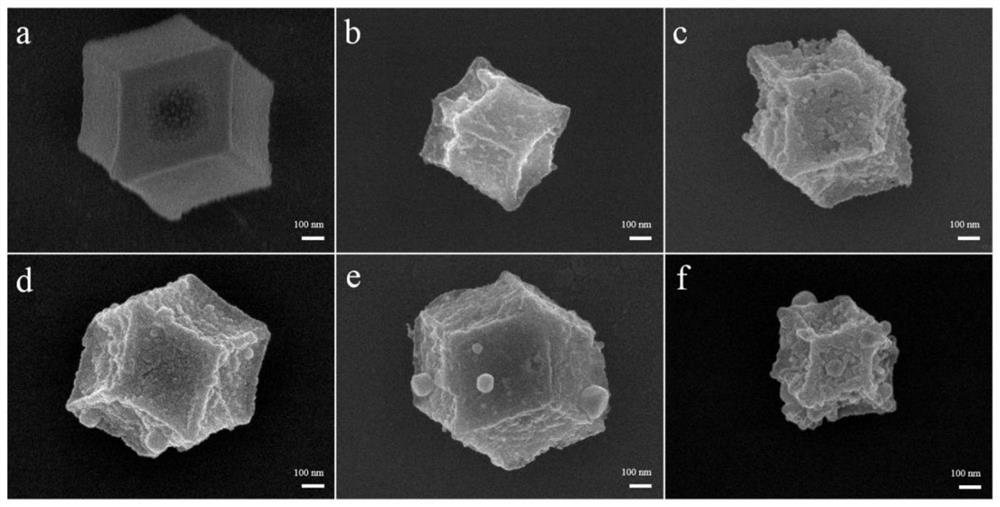

[0047] The three-dimensional structure MXene / SnO of this embodiment 2 / C negative electrode composite materials, including MXene and coated SnO 2 A mixture of metal-organic frameworks of nanoparticles, in which SnO 2 Nanoparticles are coated on the surface of the metal-organic framework to form a core-shell structure. Among them, the transition metal in MXene is one or more of Ti, V, and Nb, and the metal-organic framework is ZIF-67.

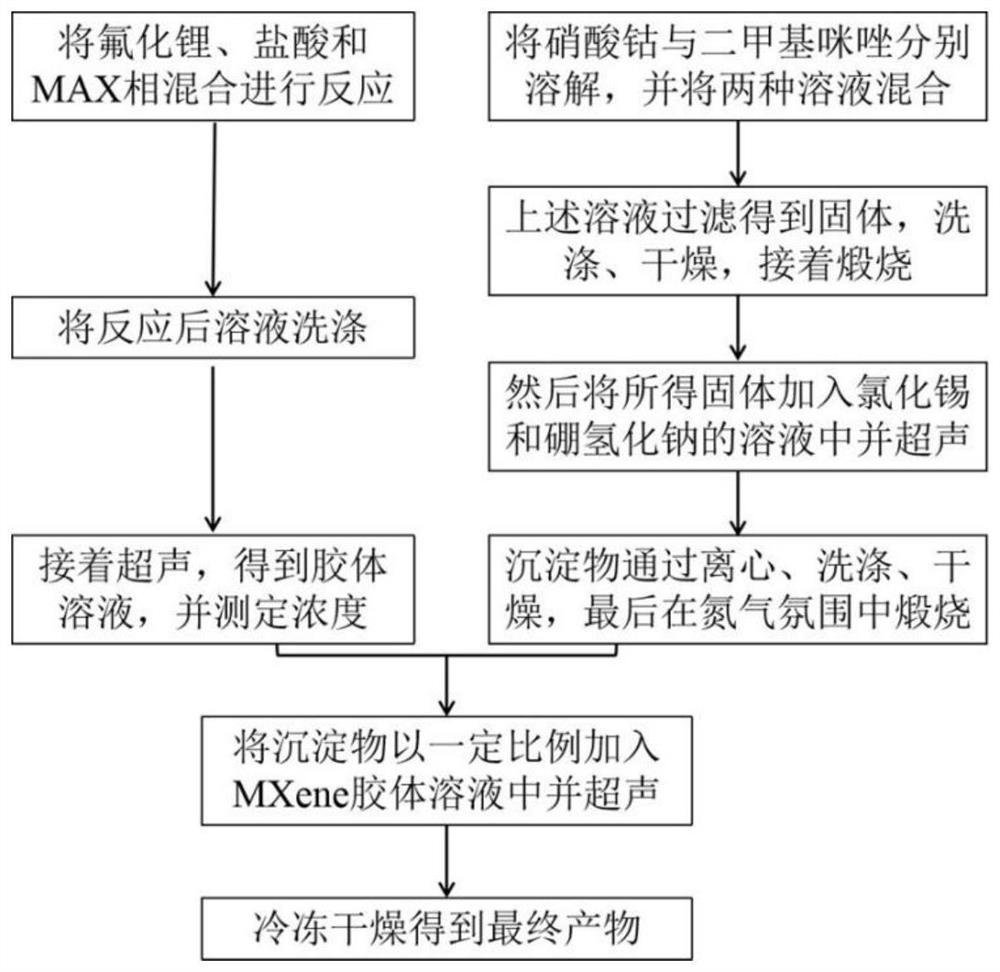

[0048] refer to figure 1 , the three-dimensional structure MXene / SnO of this example 2 The preparation method of / C negative electrode composite material comprises the following steps:

[0049] S1: Preparation of two-dimensional material MXene

[0050] Add 2gLiF into 20mL hydrochloric acid solution, the concentration of hydrochloric acid is 9M, stir for 30min, and the rotation speed is 400rpm. Then the 2gMAX-Ti 3 AlC 2 Slowly add to the beaker, and the adding process should be controlled over 10 minutes; adjust the reaction temperature t...

Embodiment 2

[0061] This example is basically the same as Example 1, except that the three-dimensional structure MXene / SnO of this example 2 In the preparation method of / C negative electrode composite material:

[0062] S3: Preparation of core-shell structure

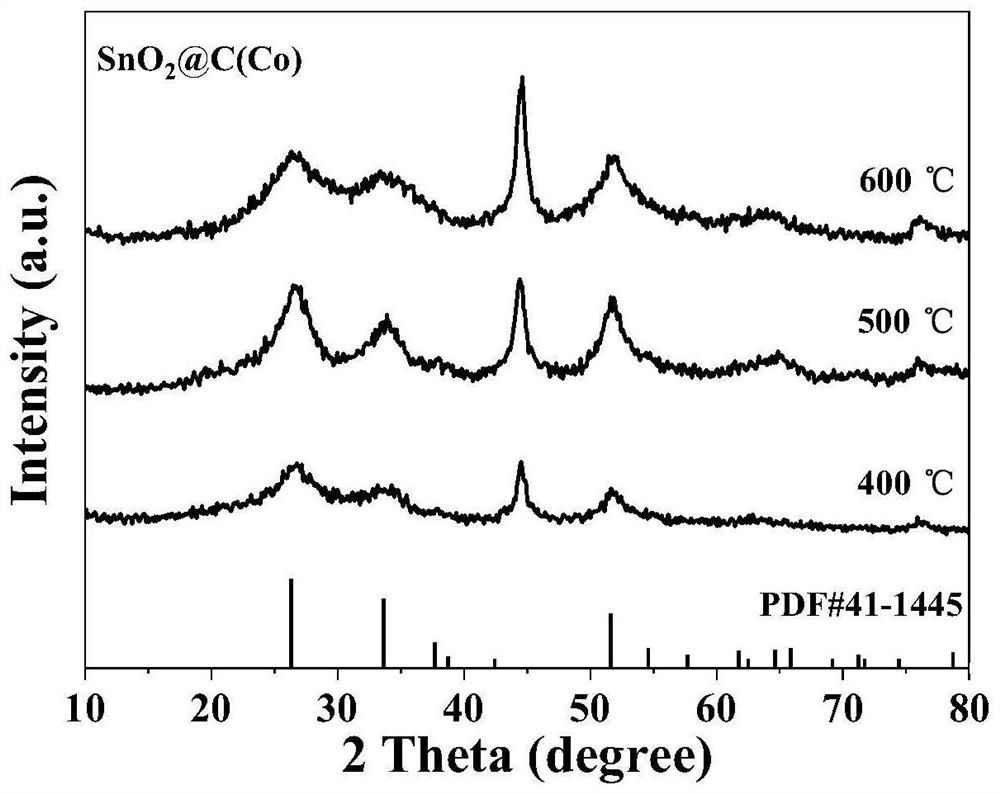

[0063] The template was added to the methanol solution of tin chloride, and ultrasonically dispersed for 30 minutes. Add excess NaBH to the mixed solution 4 , Stir vigorously at room temperature for 1 to 2 hours to generate a precipitate. The precipitate was centrifuged and washed alternately with anhydrous methanol and deionized water, 4-8 times each; after washing, it was then dried overnight in vacuum at 60°C. The dried product was heated to 500° C. in a nitrogen atmosphere, then kept at temperature for 2 h, and then cooled to room temperature to obtain a black solid product.

[0064] S5: Chemical performance test

[0065] First, the three-dimensional structure MXene / SnO 2 / C negative electrode composite material, binder, ...

Embodiment 3

[0068] This example is basically the same as Example 1, except that the three-dimensional structure MXene / SnO of this example 2 In the preparation method of / C negative electrode composite material:

[0069] S3: Preparation of core-shell structure

[0070] The template was added to the methanol solution of tin chloride, and ultrasonically dispersed for 30 minutes. Add excess NaBH to the mixed solution 4 , Stir vigorously at room temperature for 1 to 2 hours to generate a precipitate. The precipitate was centrifuged and washed alternately with anhydrous methanol and deionized water, 4-8 times each; after washing, it was then dried overnight in vacuum at 60°C. The dried product was heated to 600° C. in a nitrogen atmosphere, then kept at temperature for 2 h, and then cooled to room temperature to obtain a black solid product.

[0071] S5: Chemical performance test

[0072] First, the three-dimensional structure MXene / SnO 2 / C negative electrode composite material, binder, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial discharge capacity | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com