Composite oligosaccharide enzyme for reducing uric acid and preparation method thereof

A technology for lowering uric acid and enzymes, applied in the field of enzymes, can solve problems such as large side effects, and achieve the effects of improving shelf life, easy availability of raw materials, and stable preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

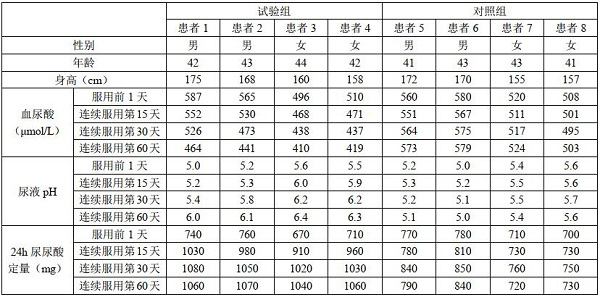

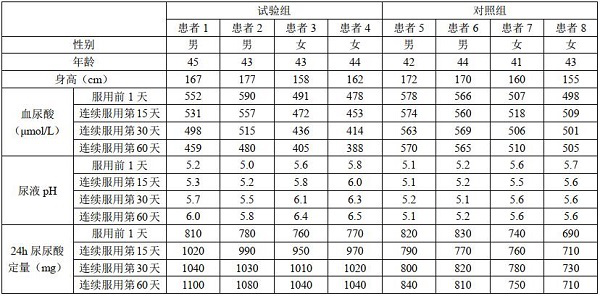

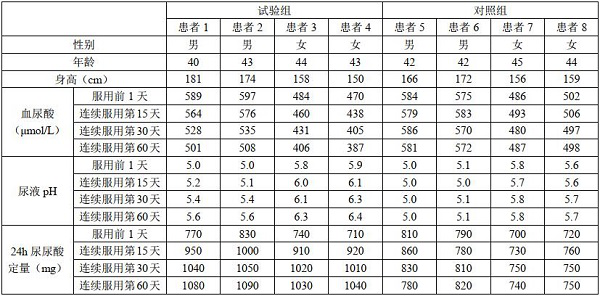

Image

Examples

Embodiment 1

[0026] Example 1: A enzyme enzyme complex oligosaccharides acid drop, mainly formed by the mass ratio of raw material: extract Plantago 5kg, wolfberry extract 3kg, 0.1kg of zinc yeast, brown sugar, 5kg, tea flower extract 7kg, grape seed powder 5kg, distilled water 60kg, daylily powder 10kg, chitosan oligosaccharide 1kg, vitamin A0.01kg, rosemary extract 0.05kg.

[0027] Specific method for preparing the starting material are as follows:

[0028] (1) Plantago extract, wolfberry extract, zinc yeast, brown sugar, tea flower extract, grape seed powder, distilled water, lily powder according to the ratio added to the fermentation kettle and mixing evenly, fermentation at 43 ℃ 60 days, to give dark brown and have a sweet and sour fermentation product; (2) the fermentation product was filtered, slag, and the filtrate was collected; (3) the filtrate was added to the formulating tank, while according to the ratio of chitosan oligosaccharide was added to the reactor deployment, vitamin aft...

Embodiment 2

[0033] Example 2: A composite drop acid oligosaccharide enzyme enzymes, mainly formed by the mass ratio of raw material: extract Plantago 8kg, wolfberry extract 5kg, 0.2kg of zinc yeast, brown sugar 6kg, tea flower extract 8kg, grape seed powder 7kg, distilled water 62kg, lily powder 15kg, oligochitosan 2kg, vitamin A0.02kg, rosemary extract 0.07kg.

[0034] Specific method for preparing the starting material are as follows:

[0035](1) Plantago extract, wolfberry extract, zinc yeast, brown sugar, tea flower extract, grape seed powder, distilled water, lily powder according to the ratio added to the fermentation kettle and stir 62 days fermentation at 45 ℃, to give dark brown and have a sweet and sour fermentation product; (2) the fermentation product was filtered, slag, and the filtrate was collected; (3) the filtrate was added to the formulating tank, while according to the ratio of chitosan oligosaccharide was added to the reactor deployment, vitamin after a, rosemary extract a...

Embodiment 3

[0040] Example 3: A Reduced uric acid enzyme enzyme complex oligosaccharides, mainly by the mass ratio of raw materials: 6.5kg Plantago extract, wolfberry extract 4kg, zinc yeast 0.15kg, 5.5kg brown sugar, tea flower extract 7.5kg, grape seed powder 6kg, distilled water 61kg, daylily powder 12.5kg, chitosan oligosaccharide 1.5kg, vitamin A0.015kg, rosemary extract 0.06kg.

[0041] Specific method for preparing the starting material are as follows:

[0042] (1) Plantago extract, wolfberry extract, zinc yeast, brown sugar, tea flower extract, grape seed powder, distilled water, lily powder according to the ratio added to the fermentation kettle and stir 61 days fermentation at 44 ℃, to give dark brown and have a sweet and sour fermentation product; (2) the fermentation product was filtered, slag, and the filtrate was collected; (3) the filtrate was added to the formulating tank, while according to the ratio of chitosan oligosaccharide was added to the reactor deployment, vitamin aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com